27

E. Additional refrigerant charging

Charge the additional refrigerant as liquid state with the gauge.

If the additional refrigerant can not be charged totally when the outdoor stops, charge it at the trial mode.

If the unit runs for a long period in the state of lack of refrigerant, compressor will occur failure.

(the charging must be nished within 30 minutes especially when the unit is running, meanwhile charging the

refrigerant).

A. Charging amount when out of factory excludes the refrigerant in the pipe.

B. The unit only is charged the standard volume of refrigerant (distributing pipe length is 0m).

Additional charging amount=actual length of liquid pipe x additional amount per meter liquid pipe

Additional charging amount=L1×0.35+L2×0.25+L3×0.17+L4×0.11+L5×0.054+L6×0.022

L1: total length of 22.22 liquid pipe

L2: total length of 19.05 liquid pipe

L3: total length of 15.88 liquid pipe

L4: total length of 12.7 liquid pipe

L5: total length of 9.52 liquid pipe

L6:total length of 6.35 liquid pipe

C. Refrigerant charging and additional charging

Note:

• To prevent the different oil into the pipe, please use the special tool for R410A, especially for gauge manifold and

charging hose.

• Mark the refrigerant type in different colour on the tank. R410A is pink.

• Must not use the charging cylinder, because the R410A will change when transferring to the cylinder.

• When charging refrigerant, the refrigerant should be taken out from the tank as liquid state.

• Mark the counted refrigerant volume due to the distributing pipe length on the label.

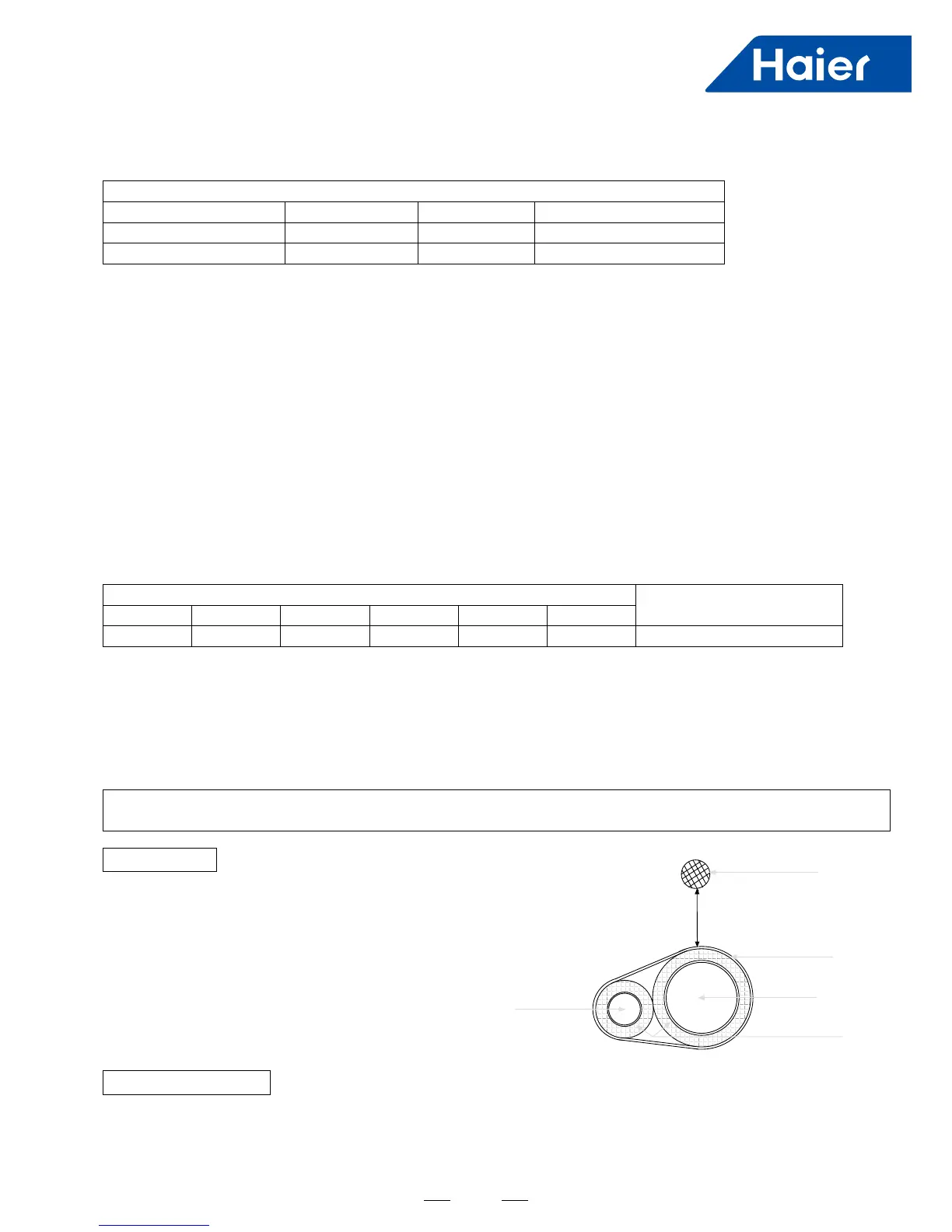

Tighten torque as the table below:

Tighten torque N.m

Shaft (valve body) Cap (cover) T-shape nut (check joint)

For gas pipe Less than 7 Less than 30 13

For liquid pipe 7.85 (MAX15.7) 29.4 (MAX39.2) 8.8 (MAX14.7)

Additional refrigerant charging per meter(kg/m)

Charge when out of factory

Ø22.22 Ø19.05 Ø15.88 Ø12.7 Ø9.52 Ø6.35

0.35 0.25 0.17 0.11 0.054 0.022 Refer to label

GWP: 2088

The product contains uorinated greenhouse gases and its functioning relies upon such gases.

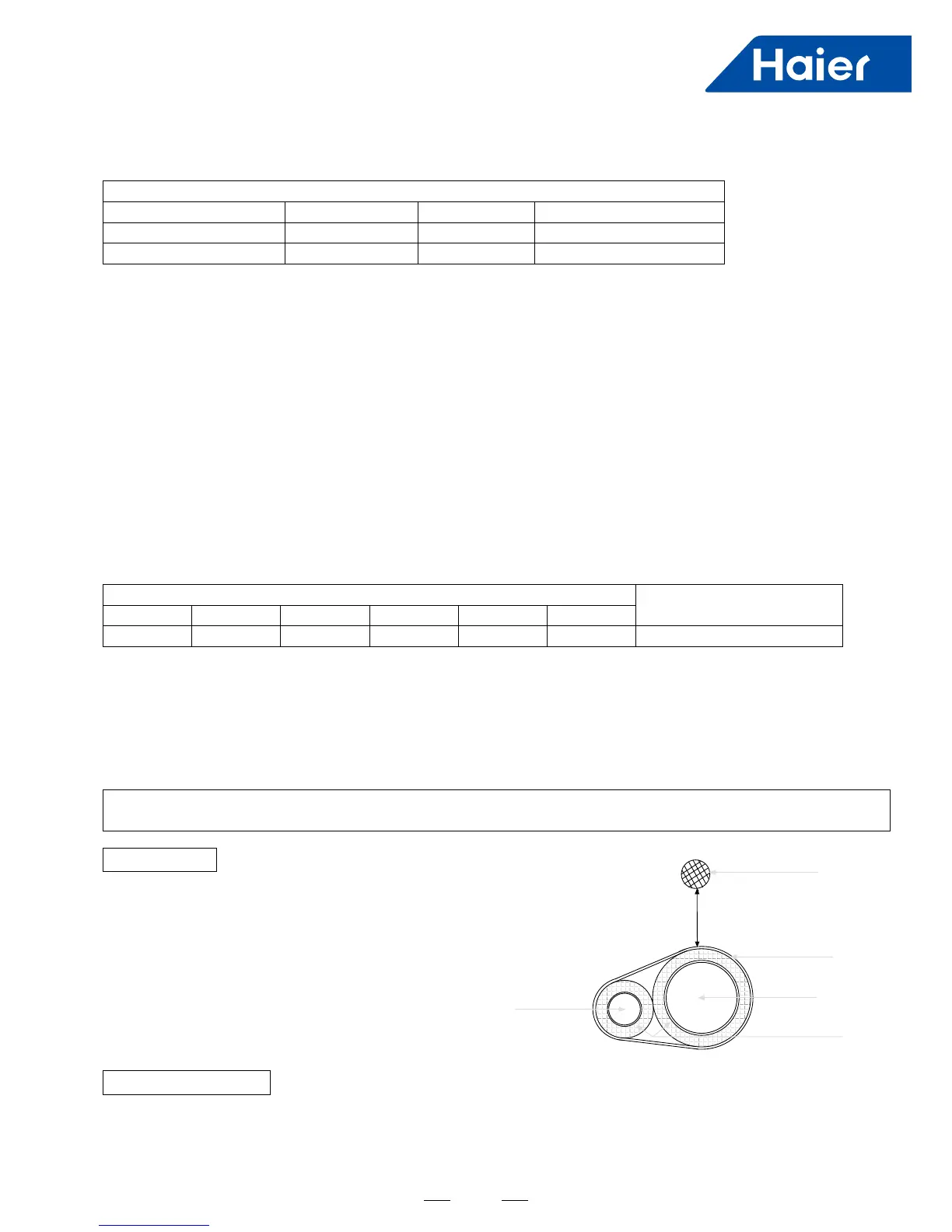

• Gas pipe and liquid pipe should be heat insulated separately.

• The material for gas pipe should endure the high

temperature over 120°C.That for liquid pipe should be over

70°C.

• The material thickness should be over 10mm, when ambient

temp. is 30°C, and the relative humidity is over 80%, the

material thickness should be over 15mm.

• He material should cling the pipe closely without gap, then

be wrapped with adhesive tape. The connection wire can not

be put together with the heat insulation material and should

be far at least 20cm.

Heat insulation

• In operation, the pipe will vibrate and expand or shrink. If not being xed, the refrigerant will focus on one part to

cause the broken pipe.

• To prevent the central stress, x the pipe for every 2-3m.

Fix the refrigerant pipe

Connection wire

over 20cm

Adhesive tape

Gas pipe

Heat insulator

Liquid pipe

Loading...

Loading...