Overview I-6

Installation Preparations

Use of welding primer

To prevent corrosion, remove the paint, grease

and other substances from new parts and welding

portions and then apply welding primer.

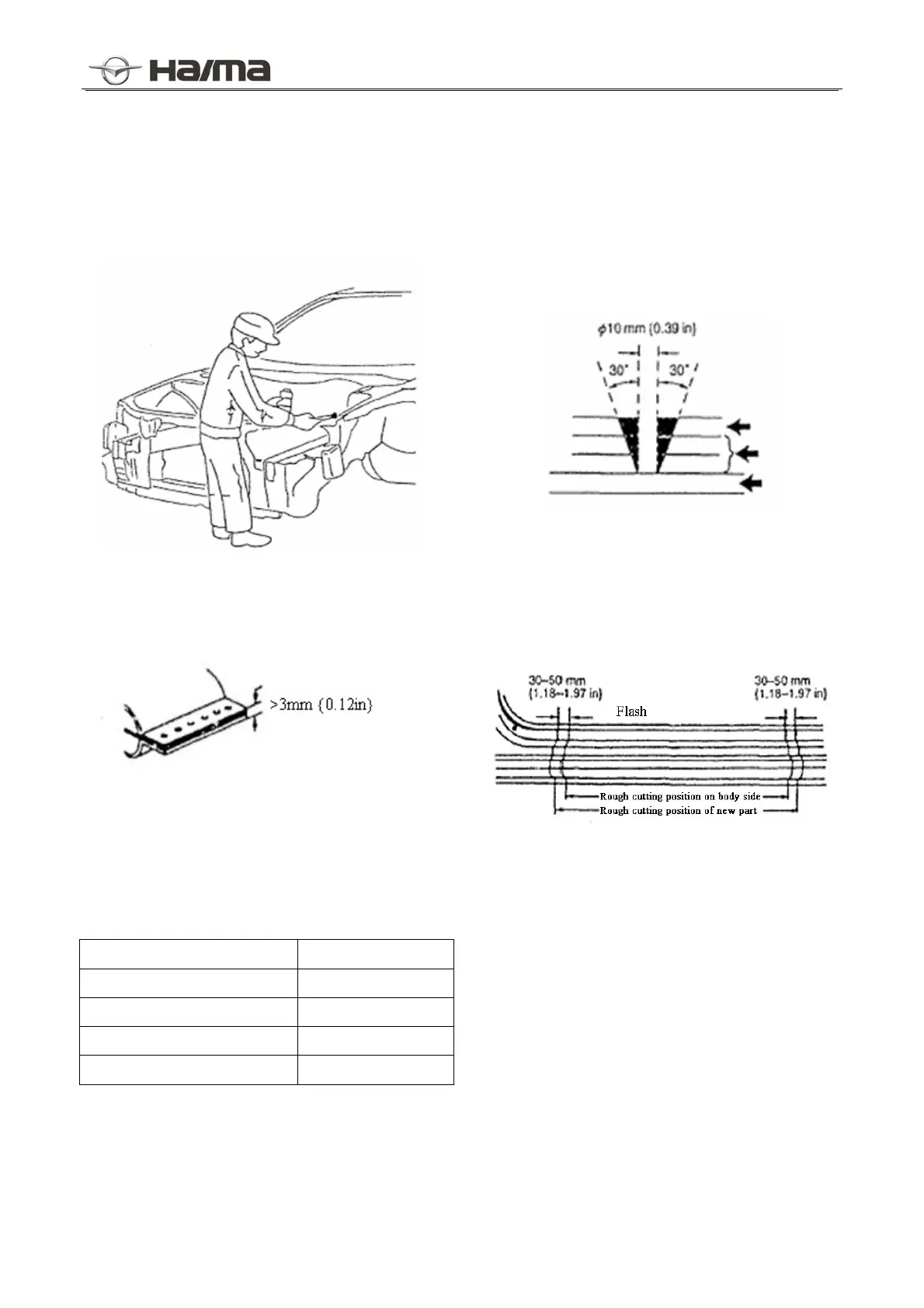

Determination of welding methods

If the overall thickness of weld points is higher

than or equals to 3mm(0.12in), adopt CO2

shielded welding for rivet welding.

Drilling for CO2 shielded welding

For the locations in which the spot welding can’t

be adopted, drill a hole with drilling machine or

hand-held drilling machine for CO2 shielded

welding.

mm {in}

Panel thickness Hole diameter

0.60-0.90{0.02-0.03} 5{0.19}

0.91-1.20{0.04-0.05} 6{0.23}

1.21-1.80{0.051-0.07} 8{0.31}

1.81-4.50{0.071-0.017} 10{0.39}

Grind the hatched portion shown in the figure below,

drill a hole on 3~4 pieces of metal panels stacked

together, and weld tightly together these metal

panels, in order to eliminate the further development

of gap.

Rough Cutting of New Parts

For cutting and splicing portions, leave

overlapping parts of 30~50mm {1.18~1.97in} on

the body side and then roughly cut the new parts.

Loading...

Loading...