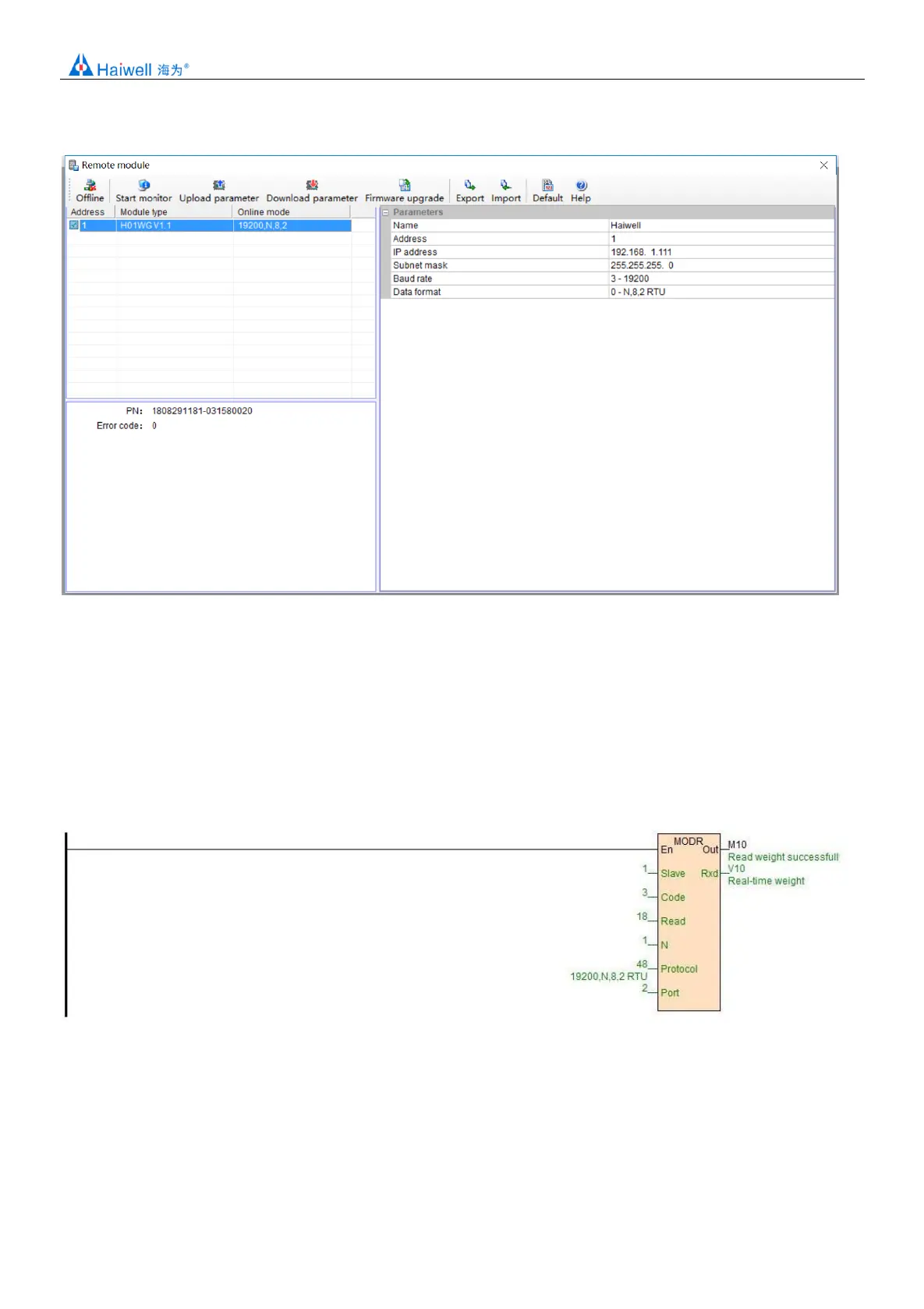

communication parameters, and then download it after modification.

6.Examples of remote IO applications: reading Module real-time weight

①:hardware wiring: the 485 ports of the host PLC and the load Cell Module are connected by the shielded twisted cable and the

A+ is connected by A+ and B- to B-. If PLC connects to multiple weighing Modules, it is necessary to connect by mode of “hand by

hand”.

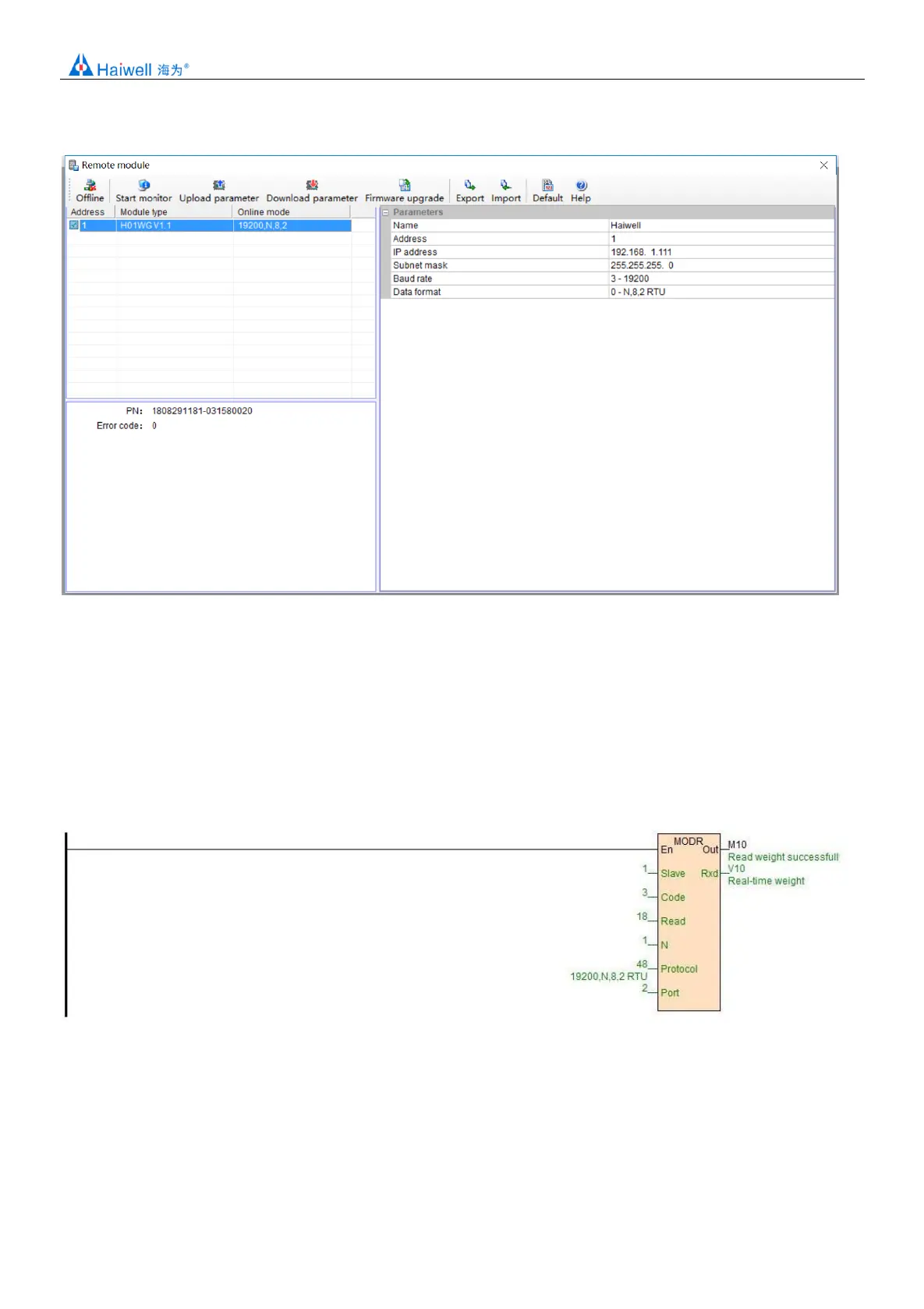

②: Modbus address: from the CR parameter table above, we can see that the H01WG Module CR 12H means the real-time

weight.

③PLC program: this example H01WG communication is the default parameter: station number 1, baud rate 19200, data format N

82 RTU. PLC reads the 4 Channels values as follows:

7.Examples of remote IO applications: calibration

The weighing Module supports three segments of calibration, and can realize multi-scale calibration. Take Channel 1 as an

example, the tutorial steps are as follows:

Step1: No weight is put on the weighing unit.

Step2: CR26H write value 1, enter the calibration mode;

Step3: Paragraph 1 is calibrated by adding a standard weight to the weighing unit and writing the weight on the current chassis

into CR27H.

Loading...

Loading...