1414

-14-

6.2. FORCED FEED LUBRICATION

All rotating elements above oil bath level are lubricated by a gear pump forcing the oil through

pressure lines.

Pumps can be either of the integral type, driven by one of the gear unit shafts, or a motorpump.

The integral type pumps are always provided with a built-in reversing device for operation in

both directions.

In case of motorpumps the direction of rotation is always indicated.

Built-on pumps reach their normal operating capacity already after a few seconds. However, in

order to avoid unwanted alarm during the start-up period, we recommend to delay the triggering

of the warning signal by 5 to 10 seconds.

Motorpumps should be switched on at least one minute before starting the

gear unit.

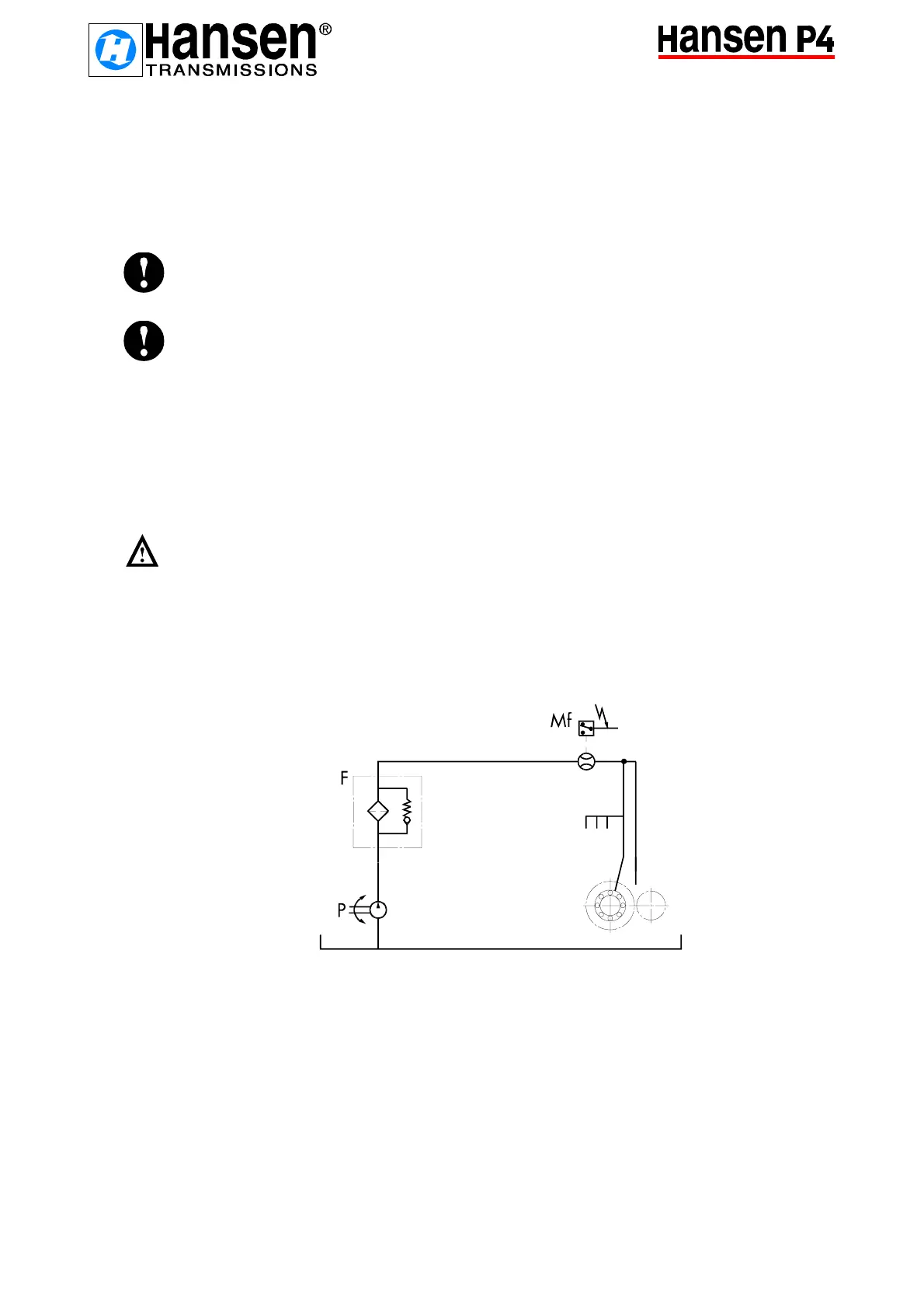

6.2.1. Circulation lubrication

- With integral pump (fig. 4).

The circulation lubrication system consists of

- a pump P

- a filter F with bypass (standard from gear unit size G onwards)

- a flow switch Mf (standard from gear unit size G onwards)

Flow switch must be wired in a circuit to automatically stop the main drive

motor when oil flow drops below alarm setting.

- With motorpump

The service manual of the lubrication and cooling system gives detailed information about the

circulation lubrication system with motorpump.

Fig. 4

6.2.2. Pressure lubrication

The service manual of the lubrication and cooling system gives detailed information about the

pressure lubrication system.

Loading...

Loading...