47HARDI

®

COMMANDER OPERATOR’S MANUAL

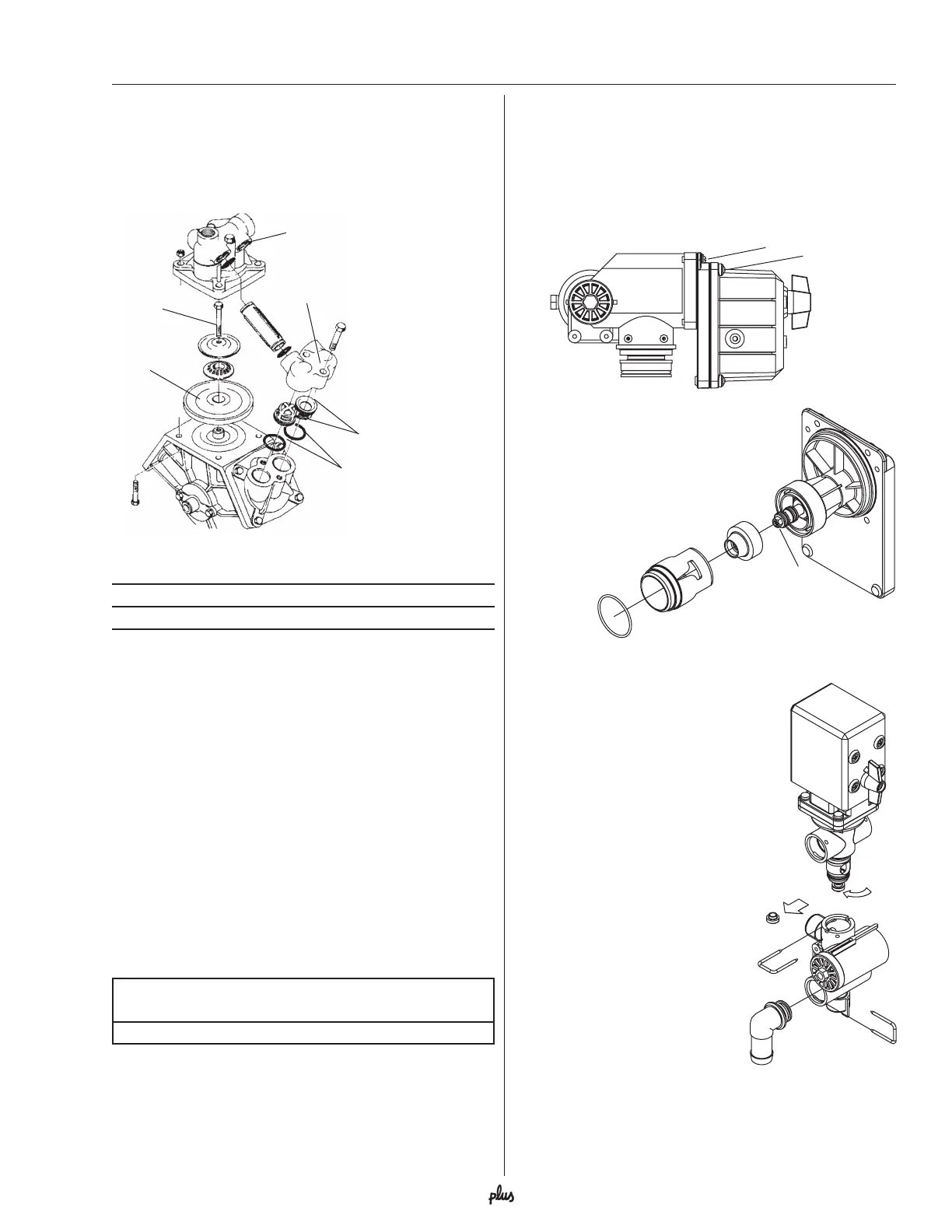

Cone check/replacement ECP operating unit

If it becomes difficult to build up sufficient pressure or if

pressure fluctuations occur, it may be necessary to

replace the cone and cylinder. A HARDI

®

kit is available

for this purpose. Ref. no. 741293.

1. Remove 4 x screws A and remove the housing.

2. Remove 4 x screws B.

3. Replace cylinder C and O-ring D.

4. Loosen the nut E, remove and replace

the cone F.

5. Reassemble in reverse order.

Cone check/replacement,

ECP distribution valve

Periodically check the distribution

valves for proper sealing. Do this by

running the sprayer with clean water

and open all distribution valves.

Cautiously remove the clip A and

pull out the hose B for the pressure

equalization device. When the

housing is drained, there should

be no liquid flow through the

pressure equalization device. If

there is any leakage, the valve

cone E must be changed.

Remove the clip C and lift the

motor housing off the valve

housing. Then unscrew the

screw D and replace the

valve cone E. Reassemble in

reverse order.

B

A

C

D

E

F

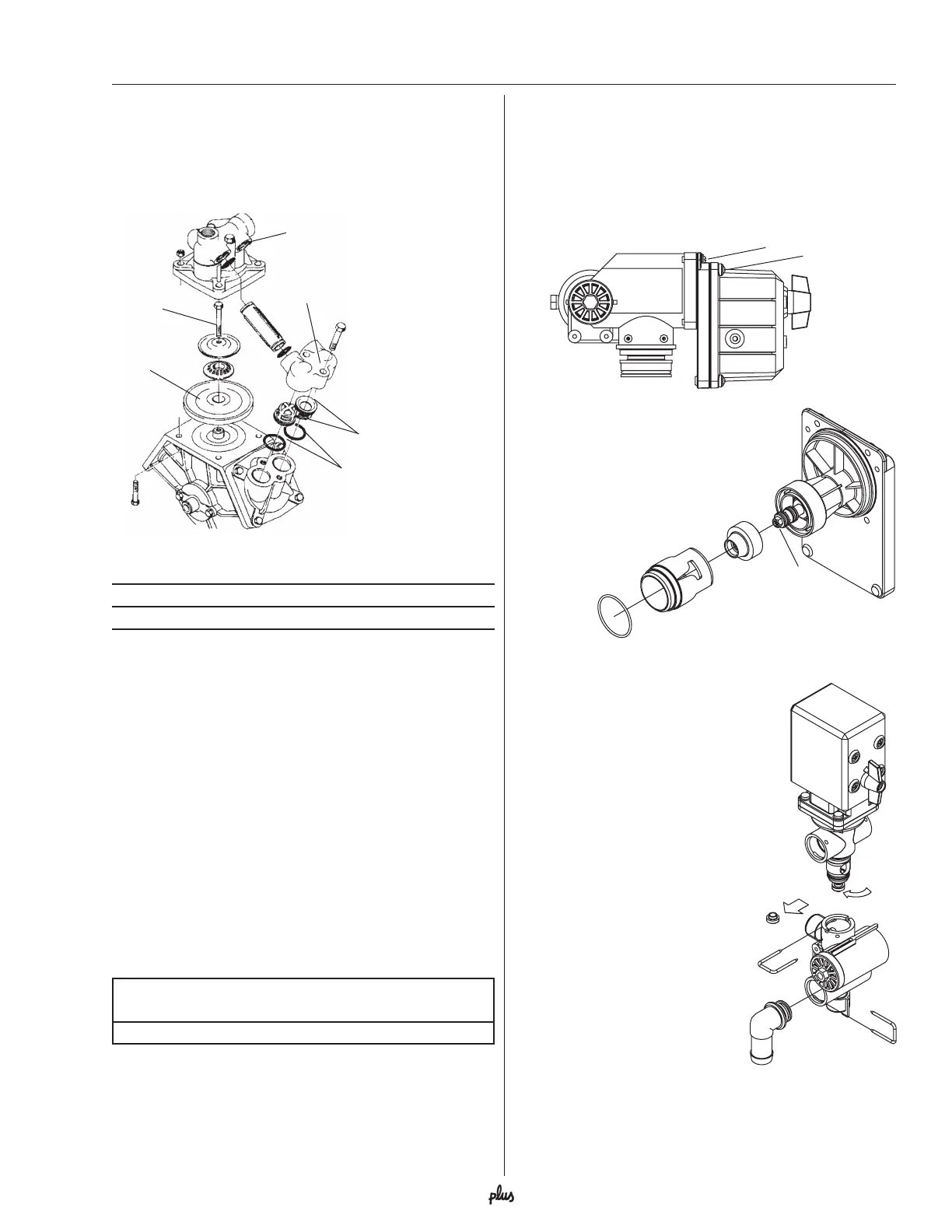

Pump valves and diaphragms replacement

(1302 pumps)

NOTE! It is recommended that if one or more

diaphragms and/or valves need replacing they all

should be replaced.

Diaphragm pump overhaul kit (valves, seals, dia-

phragms, etc.)

Pump model HARDI

®

part No.

1302 750175

Changing valves

1 Remove the valve covers (A). Before changing the

valves (B) note their orientation so they are re-

placed correctly. It is recommended to use new O-

rings (C) when changing or checking the valves.

Changing diaphragms

1 Remove the diaphragm covers (D).

2 Remove the diaphragm bolts (E).

3 The diaphragms (F) may now be changed.

4 If fluids have reached the crankcase, re-grease the

pump thoroughly. Also check the drain hole at the

bottom of the pump is not blocked.

5 Reassemble with torque settings shown below.

Torque Settings for 1302 pumps

Pump Valve Cover Diaphragm Diaphragm

Model Ft/lb(Nm) Bolt Ft/lb(Nm) Cover

1302 45 (60) 45 (60) 50 (70)

1 Ft/lb = 1.36 Nm

A

B

C

D

E

F

A = Valve Cover

B = Valves

C = O-rings

D = Diaphragm Cover

E = Diaphragm Bolt

F = Diaphragm

Maintenance

D

C

A

E

B

Loading...

Loading...