17HARDI

®

NAVIGATOR 550M, 800M, 1000M CENTRIFUGAL OPERATOR'S MANUAL

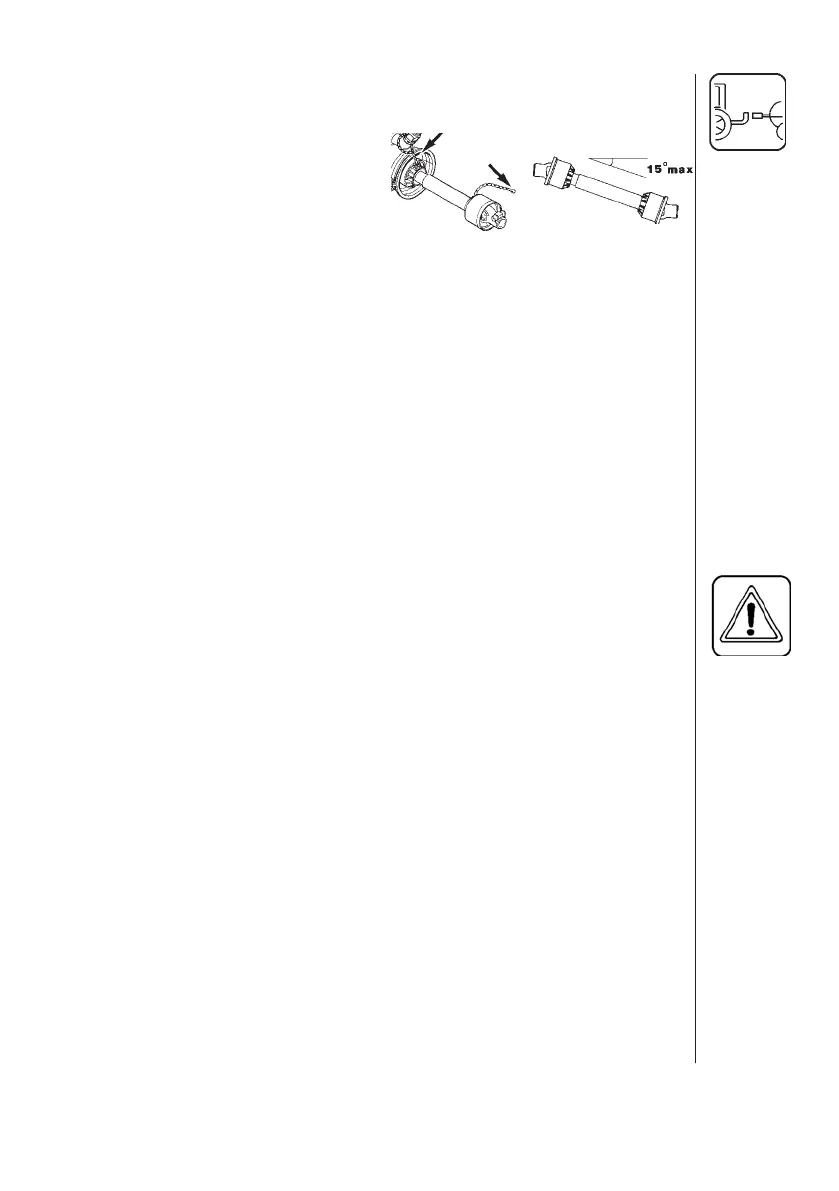

Note: Female part towards tractor. Fit the chains to prevent the protec-

tion guards r

otating with the shaft.

7. To ensure long life of the P.T.O.

shaft, try to avoid working angles

greater than 15° (Fig. 9).

3.6 Hydraulic Requirements

Eagle™ Boom:

Hydraulic booms need one single outlet for the lift function of the spray

boom and one double outlet for the folding function. Note that the hydraulic

system requires an oil capacity of approximately .8 GPM (3 LPM) and a

minimum pressure of 1,950 PSI (130 bar).

Hydraulic Driven Centrifugal Pump:

The pump motor needs one single outlet and a low pressure return outlet

on the tractor.

Note: The hydraulic driven pump system requires an oil capacity of 7

GPM (26.5 LPM)and a minimum pressure of 1000 PSI (67 bar).

BE SURE TO HOOK UP HYDRAULIC LINES PROPERLY!

ENSURE HYDRAULIC LINES HAVE NOT BEEN DAMAGED DURING

SHIPPING.

ESCAPING HYDRAULIC FLUID UNDER PRESSURE CAN

PENETRATE THE SKIN CAUSING SERIOUS INJURY. AVOID THIS

HAZARD BY RE LIEVING PRESSURE BEFORE DISCONNECTING

HYDRAULIC LINES.

ENSURE ALL CONNECTIONS ARE TIGHT BEFORE APPLYING

PRESSURE, SEARCH FOR LEAKS WITH A PIECE OF

CARDBOARD, NOT YOUR HANDS!

IMPROPER HOOK-UP CAN CAUSE DANGEROUS BOOM

MOVEMENTS AND/OR DAMAGE TO THE SPRAYER HYDRAULICS.

DO NOT ALLOW ANYONE NEAR A HYDRAULIC BOOM IN

OPERATION.

ALWAYS SHUT TRACTOR OFF WHEN CONNECTING, SERVICING

OR ADJUSTING BOOM.

Fig. 9

Loading...

Loading...