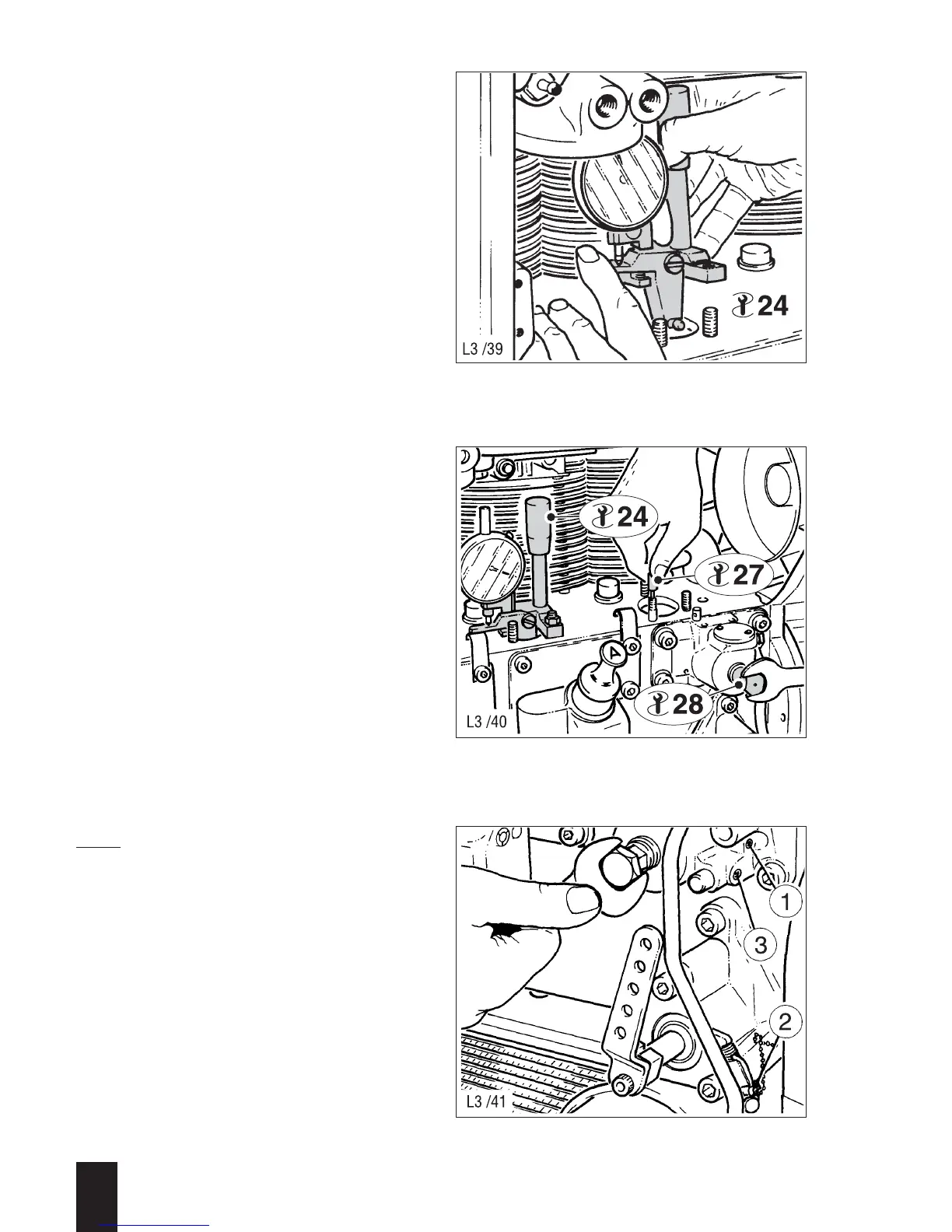

– Remove the second injection pump

(looking from the timing end) and install

measuring device - 24 - in its place (the

ball end on the vertical lever must enga-

ge in the driving slot of the governor

rod); see Fig. 144.

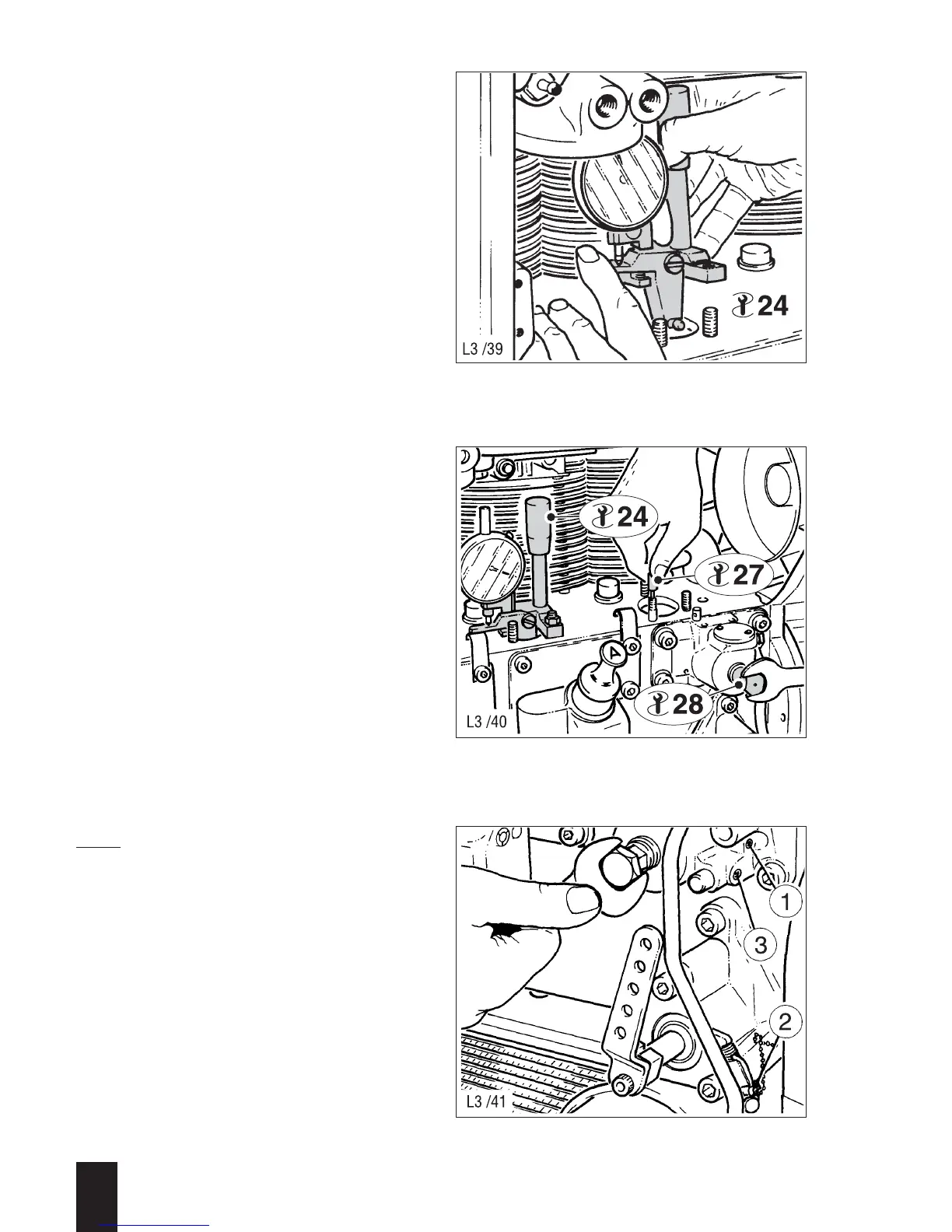

– Loosen the grub screw (146/1).

– Turn the adjusting screw (19 mm across

flats) by 1/8 of a turn counter-clockwise.

– Move the speed control lever to the

starting position.

– Insert locating pin - 27 - into the hollow-

drilled stud bolt, then turn the adjusting

screw slowly clockwise until the locating

pin engages under light pressure in the

corresponding slot of the governor rod;

Figs. 141 and 145.

This determines the „X“ position of the

governor rod.

– In this position, set the dial gauge scale

on the adjusting device precisely to „0“.

– Pull out the locating pin; the needle of

the dial gauge should then move by

0.01 - 0.02 mm.

– Determine the governor rod travel

stated on the type plate (the figure is in

hundredths of a millimetre).

– Turn the injection volume adjusting tool

until the dial gauge shows the control

distance needed. Do not forget the

0.01 - 0.02 mm already indicated by the

dial gauge.

Note:

A minus value (= lower power range) is

obtained by turning the adjusting tool

clockwise, a plus value (higher power) by

turning counter-clockwise.

– Tighten the grub screw (146/1) carefully

to prevent this setting from being lost,

and secure it with lacquer.

3

L / M . . 09.96

144

145

146

Loading...

Loading...