Checking parts:

– Examine the piston for score marks or

wear.

– Check the valve seat (111/19) for wear.

– Renew the O-rings.

Assembling the engine monitoring

block:

– Proceed in the reverse order of work

for removal.

Note:

To install the piston, use auxiliary bushing

- 34 -.

Assembly:

– Move the speed control lever to the

„Stop“ position.

– To attach, follow the instructions for de-

taching the device in the reverse order.

– Make sure that the gasket is correctly

seated and note the scribed mark which

indicates the correct position; install the

machine screws with sealant D.

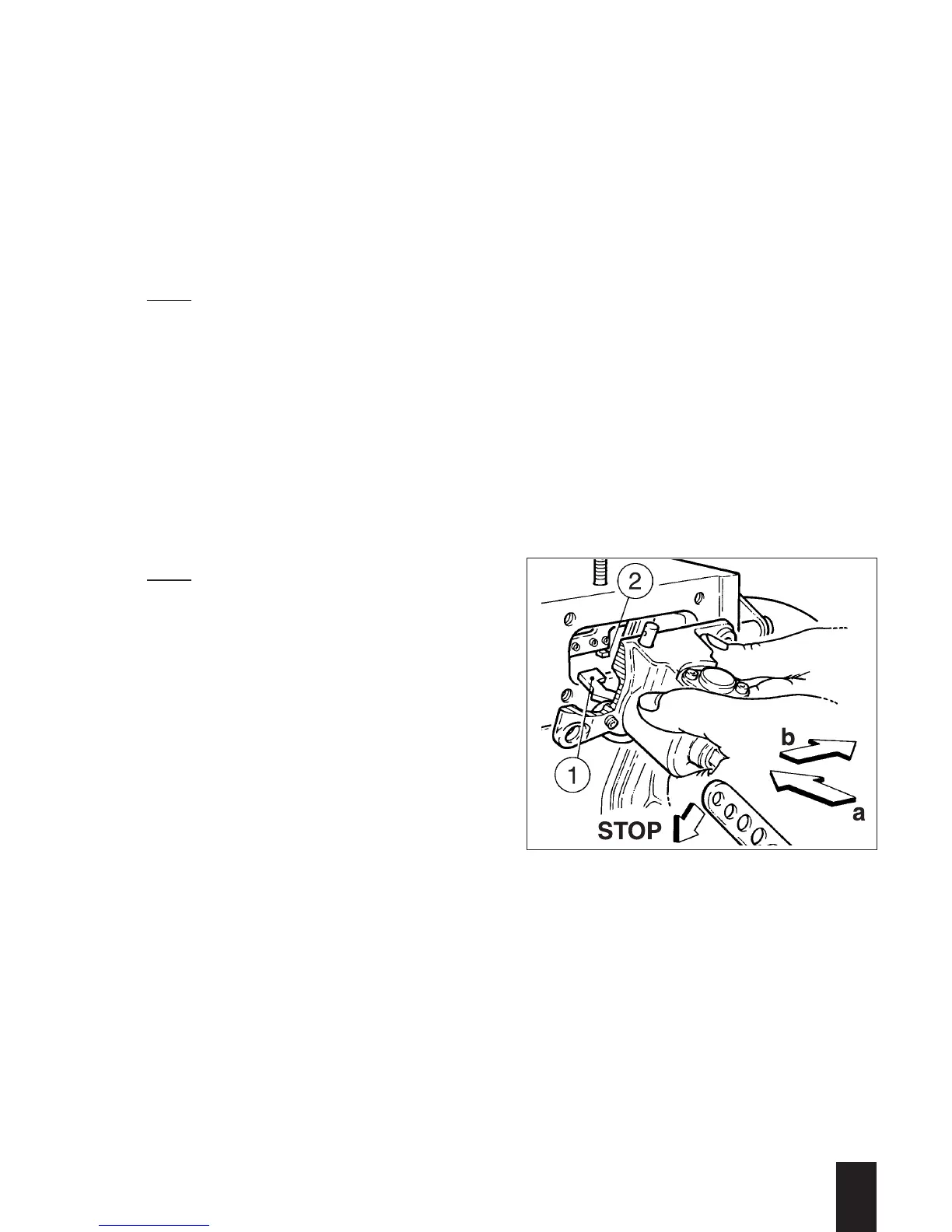

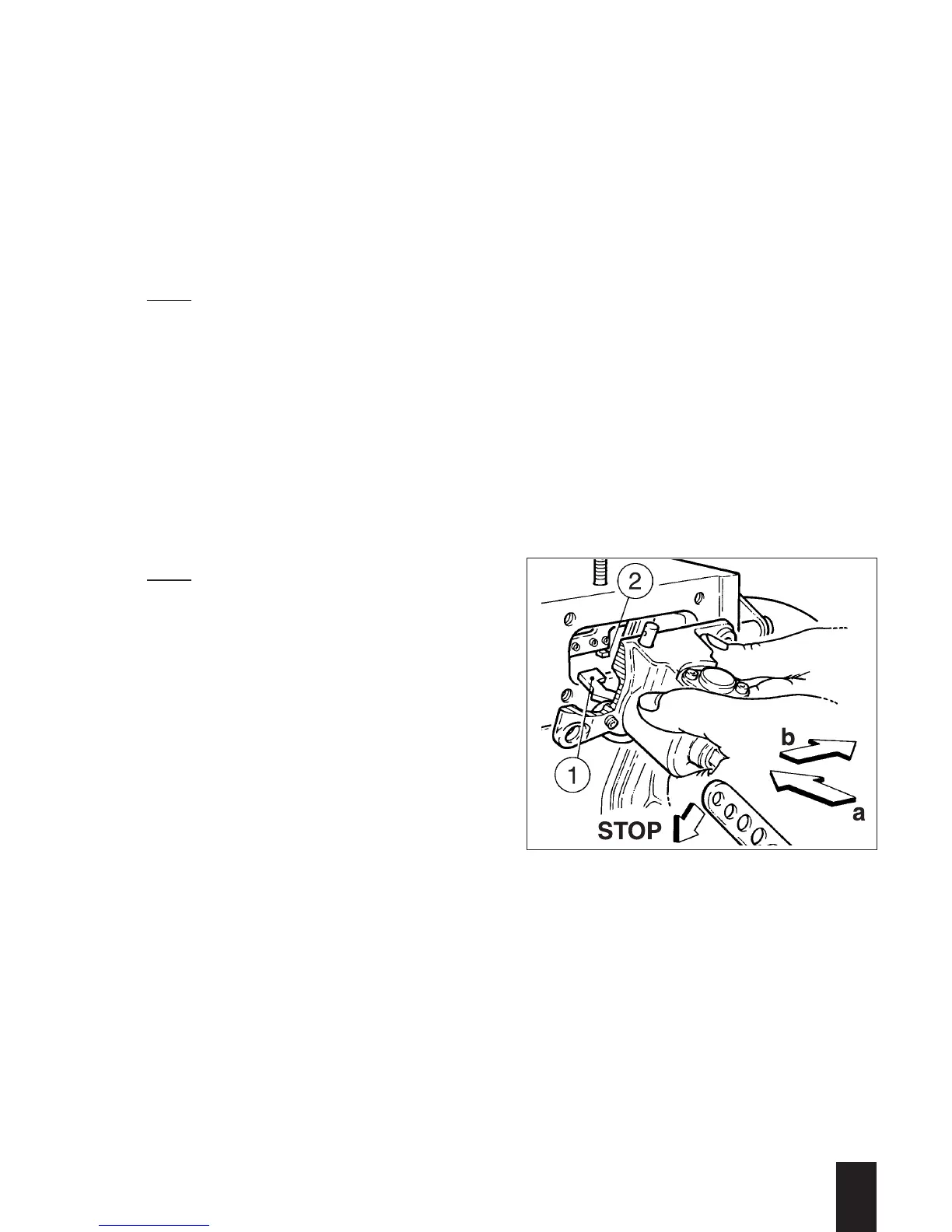

Note:

When attaching, make sure that lever

(112/1) engages to the left of plate

(112/2). To do this on engines with the lo-

wer idle speed governed to ≥ 1700 rpm

the shaft (111/12) must be turned coun-

ter-clockwise when assembling. Check

when the monitoring block is installed by

turning shaft (111/12) counter-clockwise;

it must then move back by itself to its initi-

al position.

Adjusting the engine monitoring block:

– The maximum fuel injection volume is

adjusted by turning the piston (111/18).

For adjusting the fuel injection volume

and the correct procedure see section

M 14.00. If the same monitoring block is

detached and re-attached, the fuel in-

jection volume does not need to be ad-

justed, provided that the setting of

piston (111/18) was not altered.

If the monitoring block is renewed or after

it has been repaired, the fuel injection vo-

lume (power setting) must always be

adjusted.

3

L / M . . 09.96

112

Loading...

Loading...