Checking parts:

– Check correct dimensions of bushing

for rocker (89/14), rocker shaft (89/15)

and rocker pad radius. For values, see

Section 4.

– Check valve guides and valve stems for

wear; see Section 4.

– Inspect the cylinder head for cracks (in

webs) and unevenness of the sealing

surface.

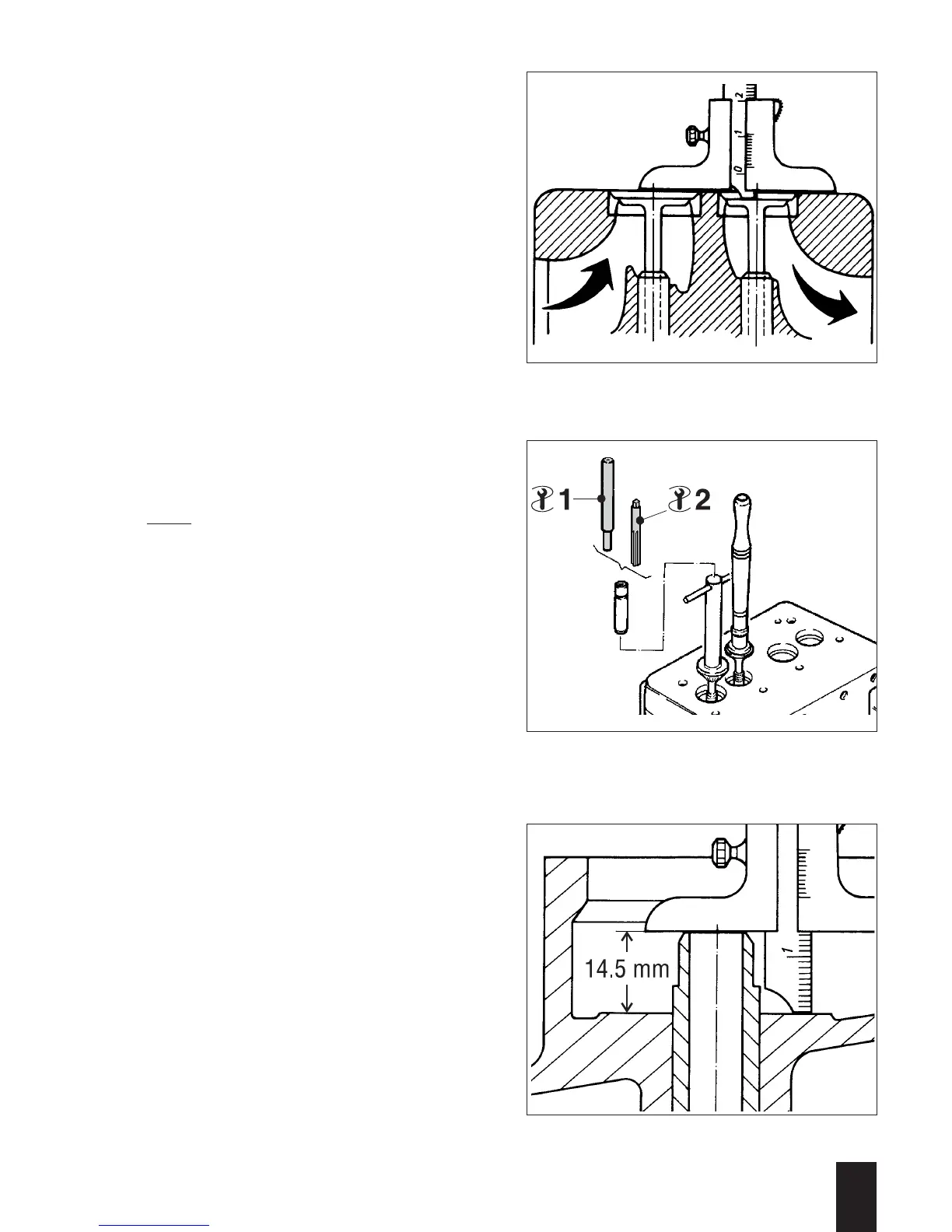

– Examine the valve seat rings and valve

collets for wear. Note valve recess in

head; see Fig. 90 and Section 4.

Reconditioning cylinder head:

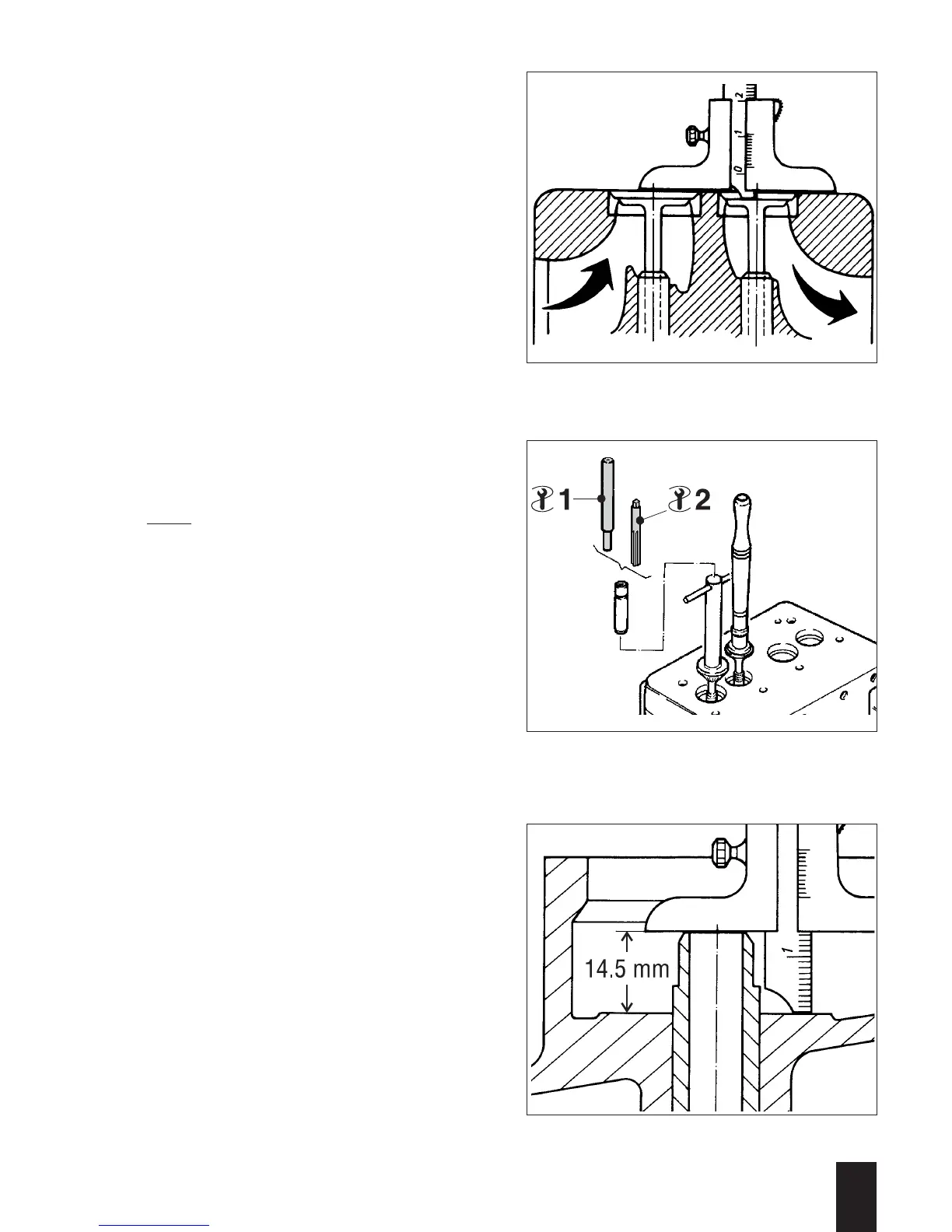

– If necessary, press the valve guides out

with pressing-in tool - 1 -, Fig. 91.

– Press in new valve guides with the

same tool - 1 -.

Note:

The pressing-in depth must be correct; for

projection, see Fig. 92.

– Ream out the valve guides to nominal

diameter with hand-held reamer - 2 -,

Fig. 91.

– If the valve seats are leaking or have

been damaged locally, or after installing

new valve guides, they must be rema-

chined. This is carried out with special

milling cutters which are available com-

mercially.

– Only mill away sufficient metal to elimi-

nate patches on the surface of the valve

seat.

– After this, lap in the valves (with grin-

ding paste, grain size 180 - 250);

see Fig. 91.

3

L / M . . 09.96

90

91

92

Loading...

Loading...