HBX CPU-1000 HVAC Controller

Version 1.38

Page 22

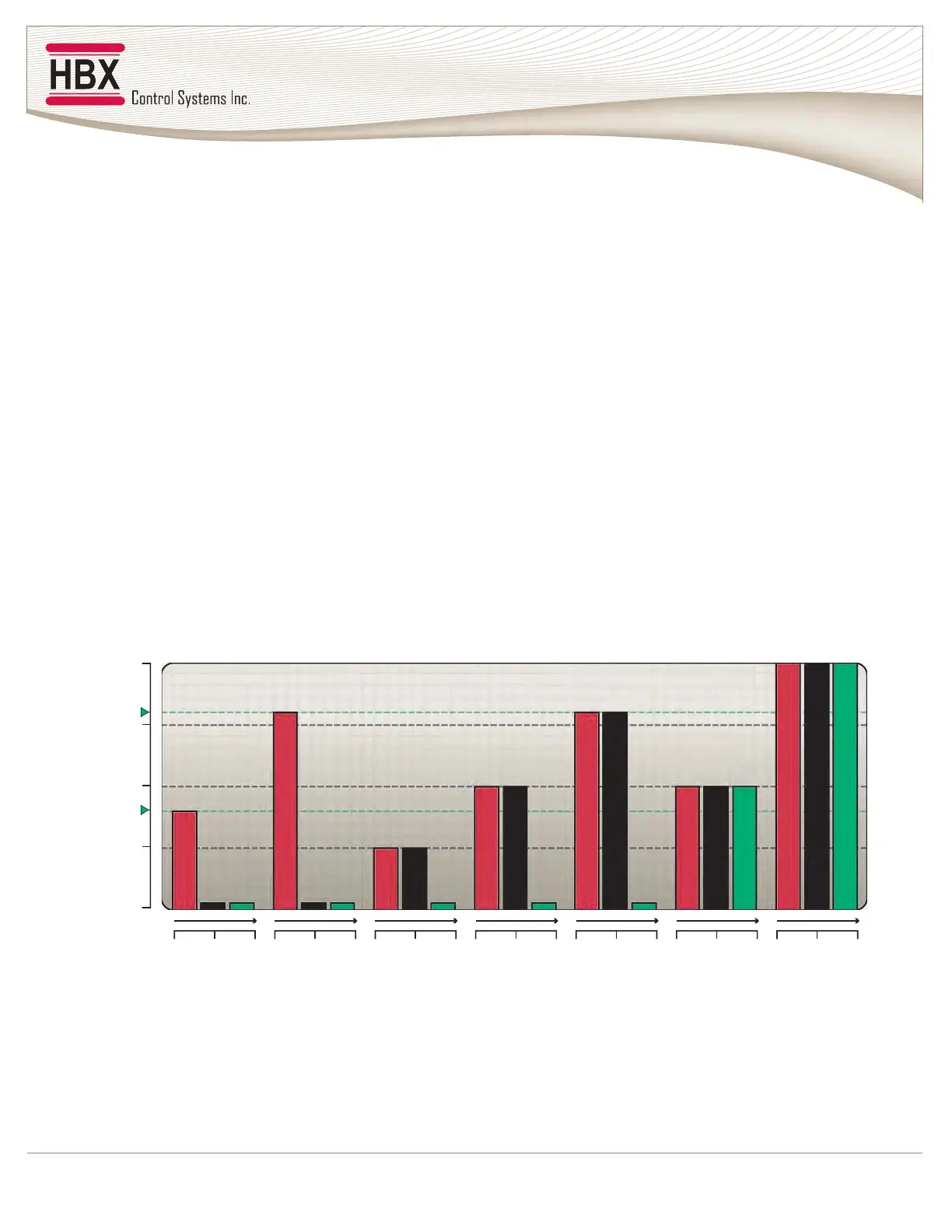

MODULATION TYPE: PROGRESSIVE

Progressive modulation is a complex algorithm for

very precise control over modulating devices. HBX

Controls has optimized the process to work effectively

for multiple modulating boilers. This modulation

algorithm is a combination of series and parallel

modulation with additional benefits.

Underlying theory causes the first boiler to modulate

from the start percent (designated by the installer

within the modulating options in of the Control) to

80% modulation. If the load still requires more heat

then boiler 1 decreases to 40%, and boiler 2 increases

from 0% to 40% (maintaining 80% output with 2

modulating boilers now on). As the load increases both

modulating boiler 1 and modulating boiler 2 will

increase to 80%. If there is still a higher load

requirement, both boiler 1 and boiler 2 will decrease to

55% and modulating boiler 3 will

increase from 0% to 55%. All 3 modulating

boilers now take on approximately the same load as

the 2 modulating boilers at 80%. This process will

continue on until all boilers set up in the system are

firing. When all the modulating boilers are firing and a

load is still required, all 3 boilers will modulate to

100% simultaneously.

As load decreases the modulating boilers will

simultaneously modulate down to the start percent.

The lag boiler will shut down and remaining

modulating boilers will increase their modulating to

split the remaining load in percent. At this point to

help with boiler cycling the Control will allow the PID

calculation to increase. This will hold the lead boiler in

the minimum fire position for longer allowing the

modulating boiler to cycle less. As a result; system

maintenance and system wear due to boiler cycling is

decreased.

BTU Output

Modulating Staging Types - Progressive

0%

100%

50%

25%

75%

Time Progression

B 2B 1 B 3 B 2B 1 B 3 B 2B 1 B 3 B 2B 1 B 3 B 2B 1 B 3 B 2B 1 B 3 B 2B 1 B 3

Loading...

Loading...