HELPFUL

KIT

BUILDING

INFORMATION

Before

attempting

actual kit

construction

read the construction

manual

through

thoroughly

to familiarize

yourself with the

general

procedure.

Note the

relative location

or

pictorials

and

pictorial inserts

m

respect

to-

the

progress

of the

assembly procedure

outlined.

This

information

is

offered primarily for the

convenience

of novice

kit

builders

and

will be of

definite

assistance

to those lacking thorough

knowledge

of

good

construction

practices* Even the advanced dec-

troriics

enthusiast

may

benefit

by a

br

ief

review

of

this material

before

proceeding

with

kit construction.

In the majority of cases*

failure

to

observe

basic

instruction

fundamentals

is

responsible

for

inability to

obtain

desired

level

of

performance.

RECOMMENDED TOOLS

The

successful

construction

of IJeathkits does not

require

the use of

specialized

equipment and

only

basic

tools

are

required. A good quality

electric

soldering

iron

is

essential. The preferred size would

be

a 100

watt iron

with

a small tip. The use of long nose

pliers

and diagonal or

side

cutting

pliers is recommended.

A small screw driver

will prove

adequate

and

several

additional assorted screw

drivers

will

be helpful.

Be sure to

obtain a good supply of

rosin

core

type radio

solder.

Never

use

separate

fluxes,

paste or

acid

solder in electronic

work.

ASSEMBLY

In

the

actual mechanical

assembly

of components

to the chassis and

panel*

it is important that the

procedure shown in the

manual

be care-

fully

followed.

Make

sure

that tube sockets

are

properly mounted in

respect

to keyway or pin

numbering

location. The same

applies to

transformer

mountings so

that the correct

transformer

color coded

wires

will

be

available

at the

proper chassis

opening.

Make it a

standard

practice

to use lock washers

under

all

6-32

and

8-32

nuts.

The only exception being in

the

use o£

solder

lugs—

the

necessary

locking

feature

is

already incorporated in

the

design of the

solder

lugs.

A control lock washer should

always

be used

between

the

control

and the chassis to

prevent

undesirable

rotation

in

the panel

To

improve

instrument appearance and to

prevent

possible

panel

marring

use a control flat

nickel

washer

under each

control

nut.

When

installing

binding posts that require the use

of

fiber

insulating

washers*

it is good practice to

slip the

shoulder

washer over the

binding

post

mounting

stud

before

installing the mounting

stud

in the

panel

hole

provided. Next, install a flat fiber

washer

and a

solder

lug

under

the

mounting

nut.

Be

sure

that the shoulder w

T

asher

is properly

centered in

the

panel

to prevent possible

shorting of

the

binding

post.

WIRING

When

following wiring

procedure

make the leads as short and direct

as possible.

In filament

wiring requiring the use of a twisted

pair

of

wires allow

sufficient slack in the

wiring that will

permit

the

twisted

pair

to

be pushed

against the

chassis as closely as possible thereby

affording

relative

isolation from adjacent parts and wiring.

When

removing

insulation

from

the end

of

hookup

w

T

ire>

it is seldom

necessary to expose

more

than a quarter inch of the wire. Excessive

insulation

removal

may cause a short

circuit

condition

in

respect

to

nearby

wiring or

terminals.

In

some

instances* transformer leads of

solid

copper

will have

a brown baked enamel coating. After the

trans-

former leads

have

been trimmed to a

suitable

length,

it is

necessary to

scrape

the enamel

coating

in

order to expose the bright copper wire

before

making

a

terminal

or soldered connection

,

In

mounting

parts such as

resistors or

condensers, trim off all excess

lead

lengths so that

the

parts may he installed in a

direct

point-to-

point

manner.

When necessary use

spaghetti

or

insulated sleeving over

exposed

wires that might

short

hi nearby wiring.

It is urgently

recommended

that the

wiring

dress

and parts layout

as

shown

in

the construction

manual

be faithfully followed. In

every

instance, the desirability

of

this arrangement was

carefully

determined

through the

construction

of a series of

laboratory

models.

SOLDERING

Much of the

performance

of the kit

instrument*

particularly in

respect

to accuracy

and stability,

depends

upon the degree

of

workmanship

used

in making soldered

connections.

Proper

soldered

connectious

are

not

at all

difficult

to make but it

would

be advisable to observe

a few

precautions.

First of

alt before

a connection

is to be

soldered, the

connection itself

should

be clean

and

mechanically

strong. Do

not

depend on

solder

alone to

hold

a connection

together.

The

tin

of the

soldering

iron

should

be

bright* clean

and

free

of excess

solder.

Use

enough heat to

thoroughly flow

the

solder smoothly into

the joint.

Avoid

excessive

use of

solder

and do not

allow

a

11 ux Hooding condition

to

occur

which

could conceivably

cause a leakage

path

between

adjacent

terminals on

switch

assemblies

and

tube

sockets. This is

particularly

important

in

instruments

such as the

YTYM,

oscillo-

scope and

generator kits. Excessive

heat will

also

burn

or damage the

insulating

material used

in the

manufacture

of switch

assemblies.

Be

sure to use

only

good quality

rosin

core radio type

solder.

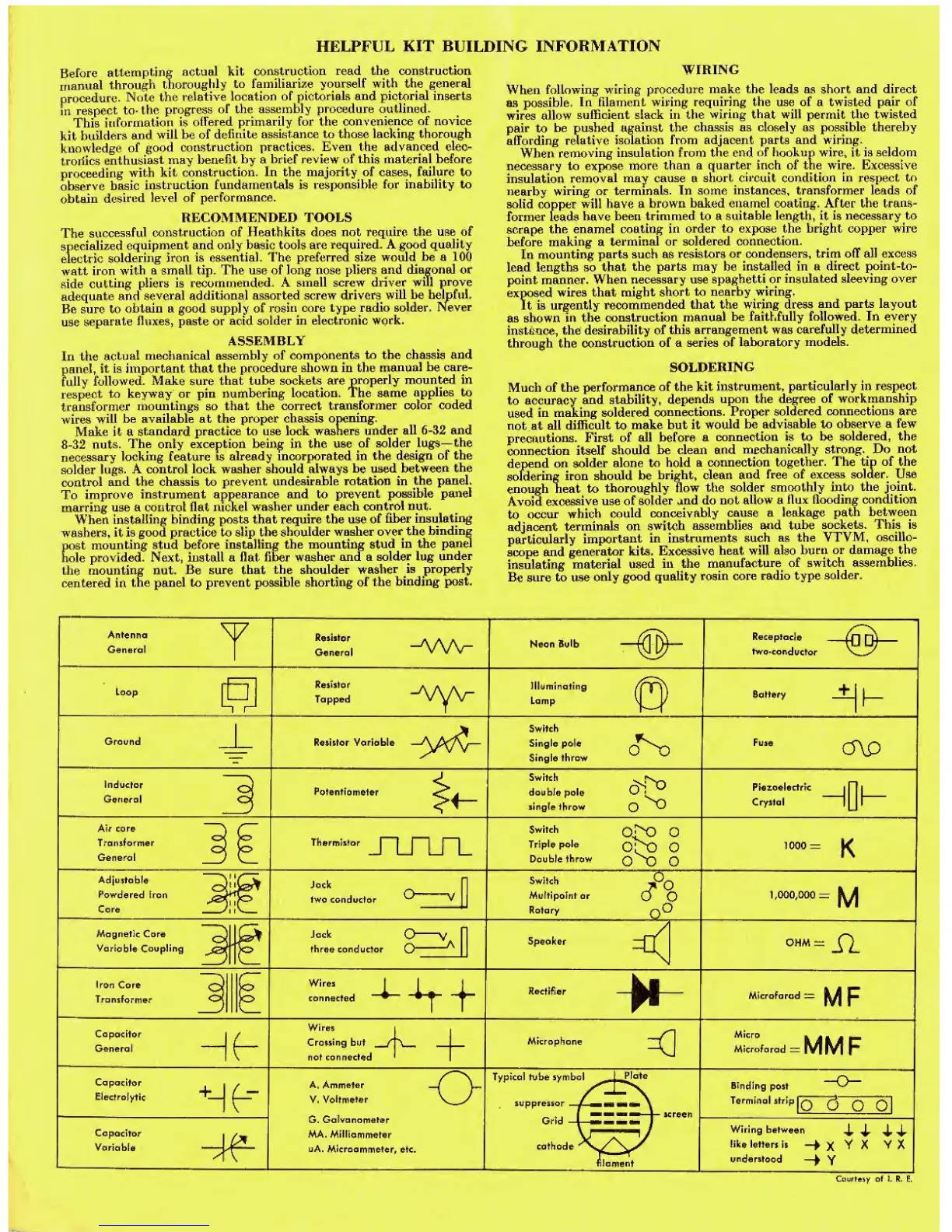

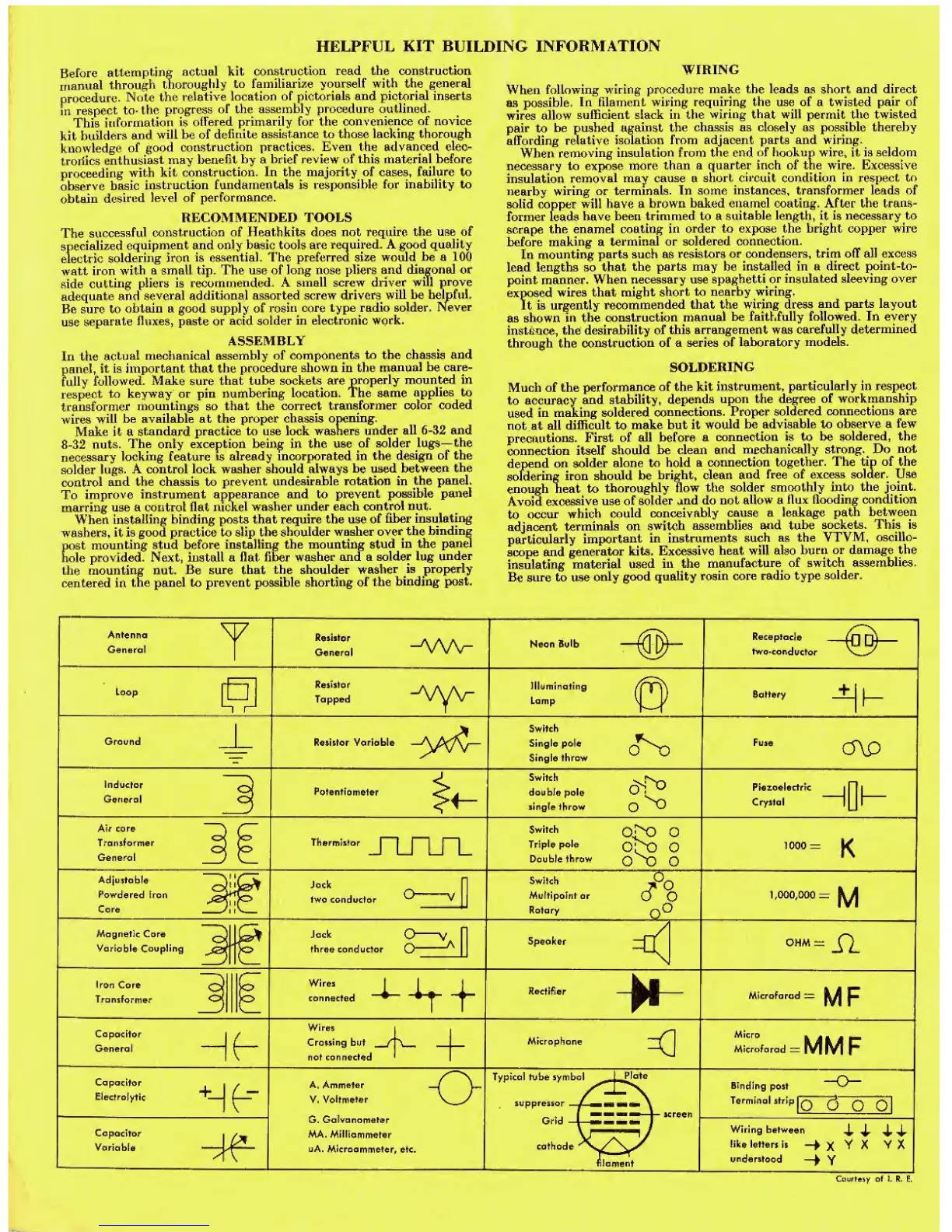

Antenna

^

General

v

-AAAr

Neon

Bulb

^

—

—

Receptacle

/j~jj

two-conductor

Loop

“

“VyV

Illuminating

/TT|\

Lamp

\JJ/

Battery

j

j

Ground

L

Resistor Variable

—

—

Switch

Single pole

C)^0

Single throw

Fui

*

cf\P

Inductor

^-0

General

Of

Potentiometer

Switch

double

pole

O

single

throw

0

TJ

Pieic electric

i UF i

Crystal

1

|J

1

Air

core

\

Transformer

X)

General

i

Thermistor

| j | j

Switch

Q^O 0

Triple

polo

OPO

0

Double

throw

Q u O

1 000

—

Adjustable

_4]

Powdered

Iron jXk

Care

J .

\f

—

r

Jock

two conductor

^

Y

Switch

4

^q

Multi point or

0 0

Rotary

q,Q

1,000,080=1

^

Magnetic Core

—A

Variable

Coupling

^^

3

*

Jack

Q

y

1

three conductor

Q

^

1

Speaker

—If

OHM

“

Iran Core

^4

Transformer

0<

Wires

.

4-

-L-

4-

connected

• w

T

y

Rectifier

—

Microfarad

“

^

j™

Capacitor

j

/

General 1 r

—

"

Wires L ,

Crossing but

_/T\

_ .

1

not connected

'

Microphone

^

]

Capacitor

.

,

Electrolytic

-

—

I

f

—

”

A.

Ammeter

-J

Y

V.

Voltmeter

V J

G. Galvanometer

MA.

Milliammeter

uA.

Microammeter,

etc.

Typical hi be symbol

__L

Plate

reen

Binding

post

G d

J

[ j

K

Terminal strip

|q

(j

q

q|

Capacitor

.

Variable

—

-L£—

cathode

filament

Wiring

between

X

-4-

4-

4

like

letters is

—

^

X

Y X V X

understood

—

^

Y

Courtesy of 1, R. E.

Loading...

Loading...