20

441 01 2121 01

Table 7 – Electrical Data

FURNACE SIZE

VOLTS−

HERTZ−

PHASE

OPERATING

VOLTAGE RANGE

MAX. UNIT

AMPS

UNIT

AMPACITY

#

MAX. WIRE

LENGTH − FT (M)}

MAX. FUSE OR

CKT BKR AMPS {

MIN. WIRE

GAUGE

Max. Min.

0701412 115−60−1 127 104 9.0 11.99 30 (9.0) 15 14

0901716 115−60−1 127 104 9.6 12.56 29 (8.8) 15 14

1102120 115−60−1 127 104 15.1 19.33 29 (8.8) 20 12

1352422 115−60−1 127 104 14.9 19.13 30 (9.0) 20 12

* Permissible limits of the voltage range at which the unit operates satisfactorily.

# Unit ampacity = 125 percent of largest operating component’s full load amps plus 100 percent of all other potential operating components’ (EAC, humidifier, etc.) full load

amps.

{Time−delay type is recommended.

}Length shown is as measured 1 way along wire path between furnace and service panel for maximum 2 percent voltage drop.

FIRE HAZARD

Failure to follow this warning could result in

personal injury, death, or property damage.

Do not connect aluminum wire between disconnect

switch and furnace. Use only copper wire.

!

WARNING

Use a separate, fused branch electrical circuit with a properly

sized fuse or circuit breaker for this furnace. See Table 7 for

wire size and fuse specifications. A readily accessible means

of electrical disconnect must be located within sight of the

furnace.

NOTE: Proper polarity must be maintained for 115−v wiring.

If polarity is incorrect, control LED status indicator light will

flash rapidly and furnace will NOT operate.

J−Box Relocation

NOTE: If factory location of J−Box is acceptable, go to next

section (ELECTRICAL CONNECTION to J−Box).

NOTE: On 14−in. (356 mm) wide casing models, the J−Box

shall not be relocated to other side of furnace casing when

the vent pipe is routed within the casing.

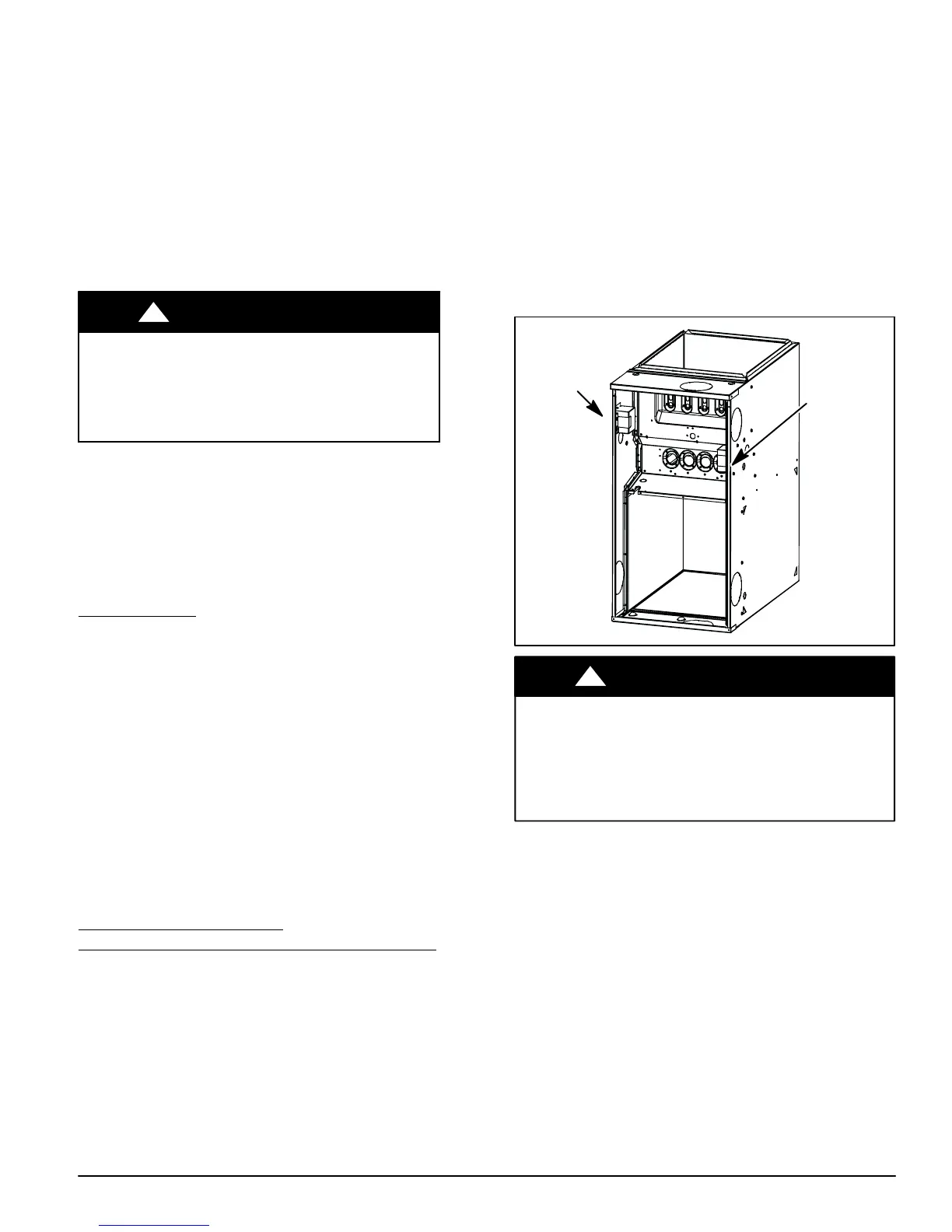

1. Remove and save two screws holding J−Box. (See

Figure 23)

NOTE: The J−Box cover need not be removed from the

J−Box in order to move the J−Box. Do NOT remove green

ground screw inside J−Box. (See Figure 23)

2. Cut wire tie on loop in furnace wires attached to J−Box.

3. Move J−Box to desired location.

4. Fasten J−Box to casing with the two screws removed

in Step 1.

5. Route J−Box wires within furnace away from sharp

edges, rotating parts and hot surfaces.

Electrical Connection to J−Box

Electrical Box on Furnace Casing Side (See Figure 24)

1. Select and remove a hole knockout in the casing

where the electrical box is to be installed.

NOTE: Check that duct on side of furnace will not interfere

with installed electrical box.

2. Remove the desired electrical box hole knockout and

position the hole in the electrical box over the hole in

the furnace casing.

3. Fasten the electrical box to casing by driving two field−

supplied screws from inside electrical box into casing

steel.

Figure 23 − Relocating J−Box

FACTORY

INSTALLED

LOCATION

ALTERNATE

FIELD

LOCATION

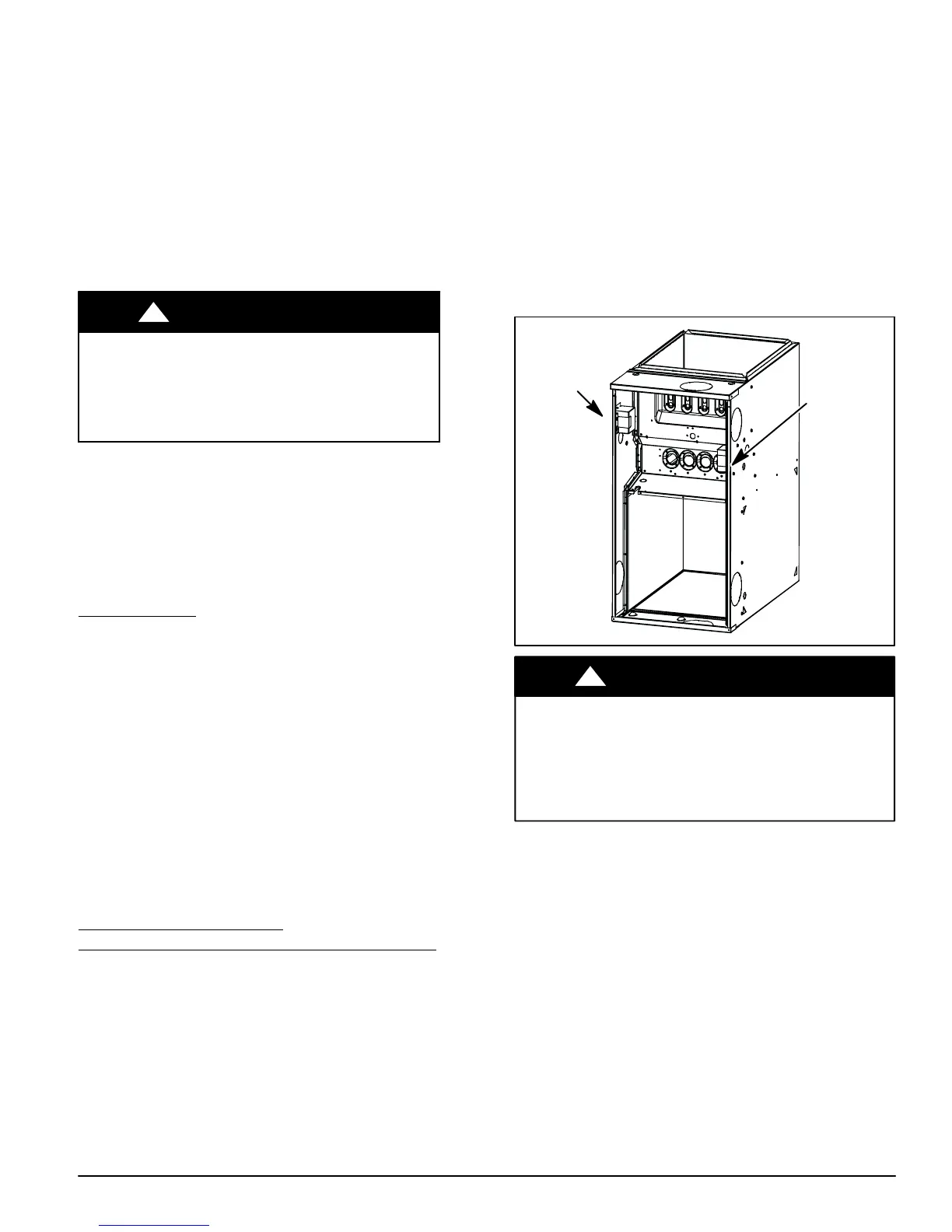

FIRE OR ELECTRICAL SHOCK HAZARD

Failure to follow this warning could result in personal

injury, death, or property damage.

If field−supplied manual disconnect switch is to be

mounted on furnace casing side, select a location

where a drill or fastener cannot damage electrical or

gas components.

!

WARNING

4. Remove and save two screws holding J−Box. (See

Figure 23)

5. Pull furnace power wires out of 1/2−in. (12 mm) diamet-

er hole in J−Box. Do not loosen wires from strain−relief

wire−tie on outside of J−Box.

6. Route furnace power wires through holes in casing and

electrical box and into electrical box.

7. Pull field power wires into electrical box.

8. Remove cover from furnace J−Box.

9. Route field ground wire through holes in electrical box

and casing, and into furnace J−Box.

10. Reattach furnace J−Box to furnace casing with screws

removed in Step 4.

11. Secure field ground wire to J−Box green ground screw.

12. Complete electrical box wiring and installation. Connect

line voltage leads as shown in Figure 24. Use best

practices (NEC in U.S. for wire bushings, strain relief,

etc.

Loading...

Loading...