Users Manual Henkovac 04-serie V2019

4.0 Installation of Machine

General

Level the machine on a flat firm surface

Position the machine in such a manner that the pump is unobstructed and properly ventilated

Engage the locks on the wheels, if so equipped

Check the oil level in the pump; add oil if necessary

o Never operate the machine when the oil level is low

Table-Top Model Mobile and Double-

Chamber Models

Electrical Connection 3-phase vacuum pump

If the machine is incorrectly hooked up to a three-phase electrical connection,

the pump will make excessive noise. If this happens, take the following steps:

Turn the pump off immediately

Switch the phase wires

Make sure that the rotation direction of the pump matches the arrow on the

motor housing

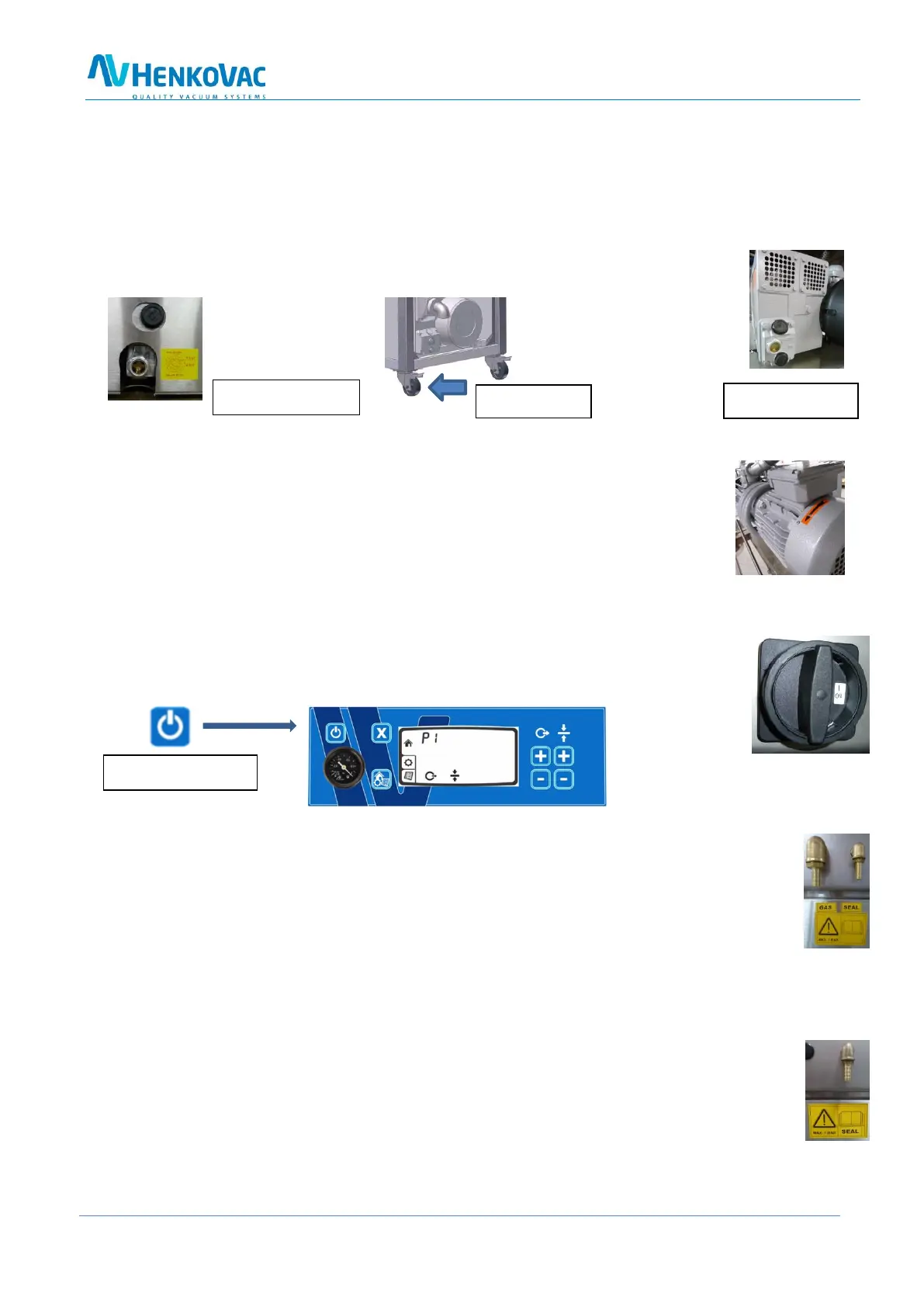

Turning on Machine

If so equipped, like some mobile and double-chamber models, turn on the main

power switch on the back of the machine

Push the on/off button on the control panel of the machine

4.1 Gas Connection for MAP Applications (Modified Atmospheric Packaging)

Connect the gas supply line to the inlet on the back of the machine

Maximum pressure: 1 bar

Anchor the gas cylinders securely to prevent them from falling over

Make sure that the work area is well-ventilated

To assure that you use the appropriate gas for your application, consult

your dealer or gas supplier

Assure a good connection and use high-quality materials

4.2 Compressed Air Connection for Additional Sealing Pressure

Additional sealing pressure is usually recommended for MAP applications only

The M4-M8 and the D1-D6 models with the option Gas/MAP are standard equipped

with a compressed air inlet

Extra sealing pressure is not necessary and not available for the Table-Top, M1, M2, M3

Consult your dealer for installation details

Maximum pressure: 1 bar

Assure a good connection and use high-quality mater

Loading...

Loading...