MANL-00005-A - D Series Rotary Dispensers.docx 26

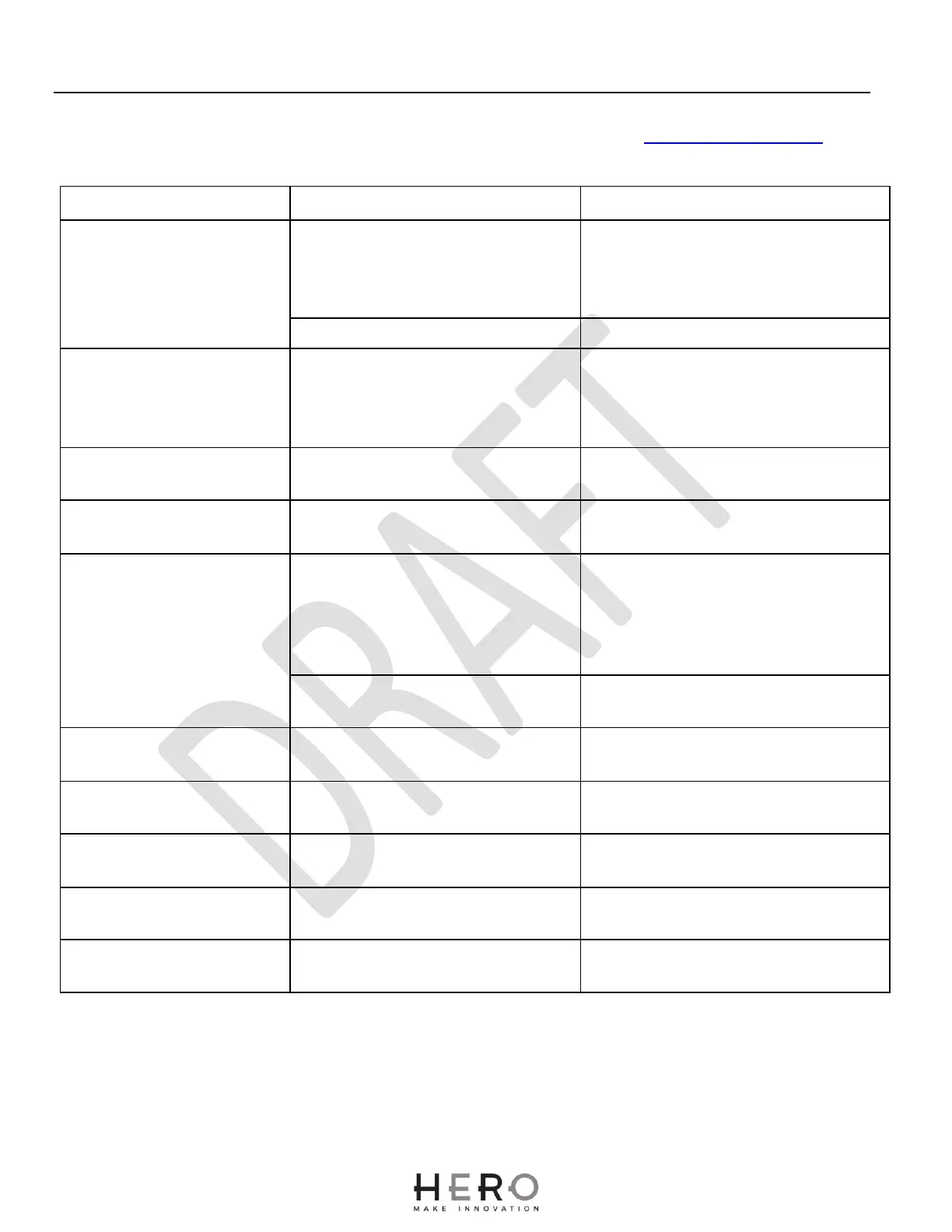

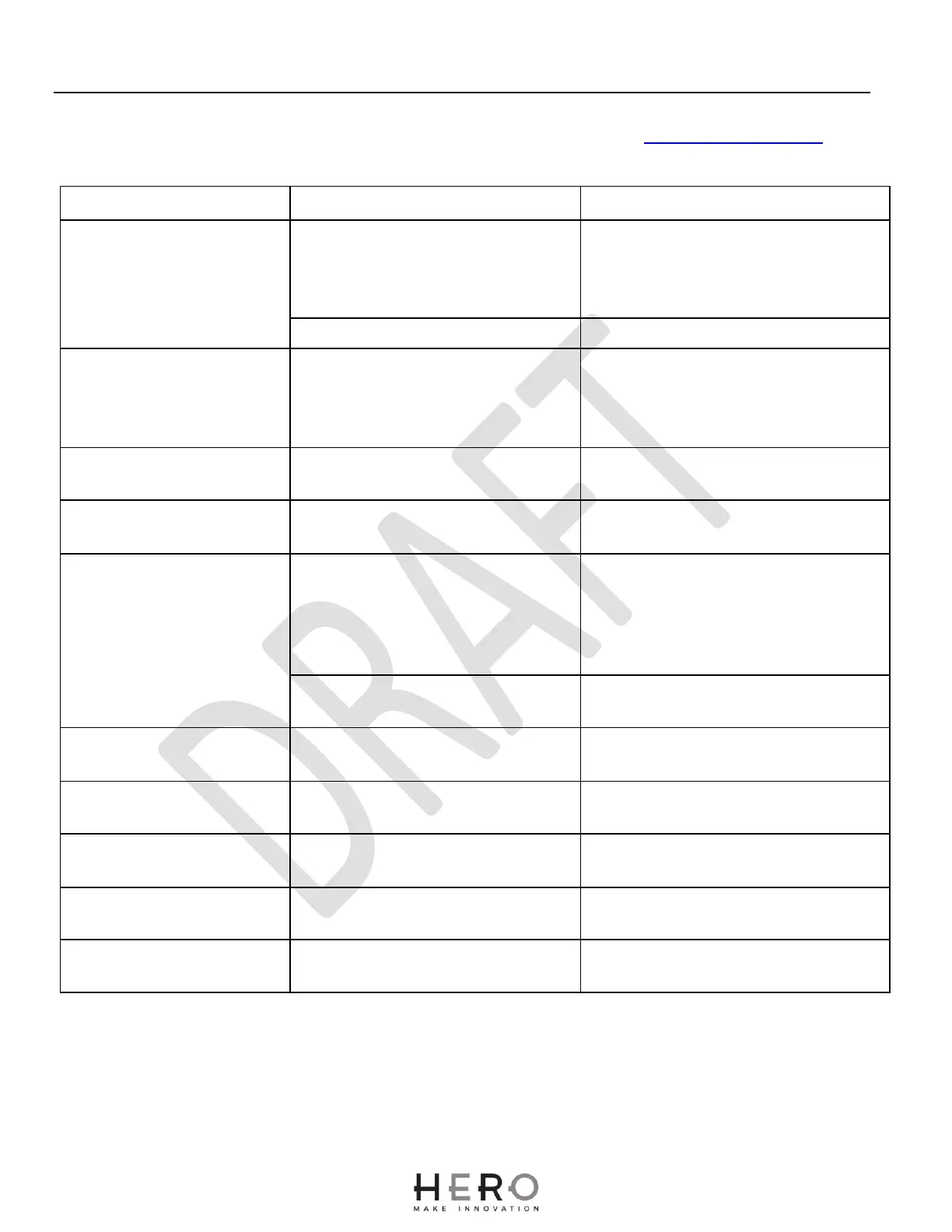

TROUBLESHOOTING

For technical support, contact HERO Customer Service at 800-494-4376 or customercare@hero.ca.

colorant from the nozzle

during dispensing

Low colorant level, allowing air into

the pump cylinder.

Fill canister and operate the plunger

several times, without opening the

valve. Dispense colorant into a paper

End cap twists or lifts during

operation.

End cap loose on cylinder.

Push down end cap onto the cylinder,

and lightly tighten the two set screws

until it can no longer be twisted by

Canister is loose on

turntable.

Tighten the mounting screws

Colorant appears on the

piston shaft, and or gauge.

Worn or loose piston seals.

Refer to replacement of piston seals

page 12.

Colorant does not dispense

easily.

Nozzle is clogged or too small.

Clear nozzle of obstructions.

If problem continues, use a larger

nozzle.

(three extra nozzles are supplied with

Thoroughly clean out canister and refill

with new colorant.

Pump tube is loose on the

canister.

Pump attaching bolts are loose.

Remove canister and tighten the bolts

Colorant leaks around the

outlet nozzle

Nozzle O-Ring is lost or damaged.

Colorant leaks around the

Accu-purge button

Clean or replace O ring as required

Colorant leaks from side of

dispenser handle.

Worn or damaged valve barrel O-

Ring

Gauge line does not line up

with plunger handle

Loading...

Loading...