Essential notes before use

Essential notes before use

A. Checking Motor ID certainly.

: Enter the motor ID indicated on the motor name plate to the parameter of “P01-01”.

For details on the motor ID, refer to Chapter 3 of this manual.

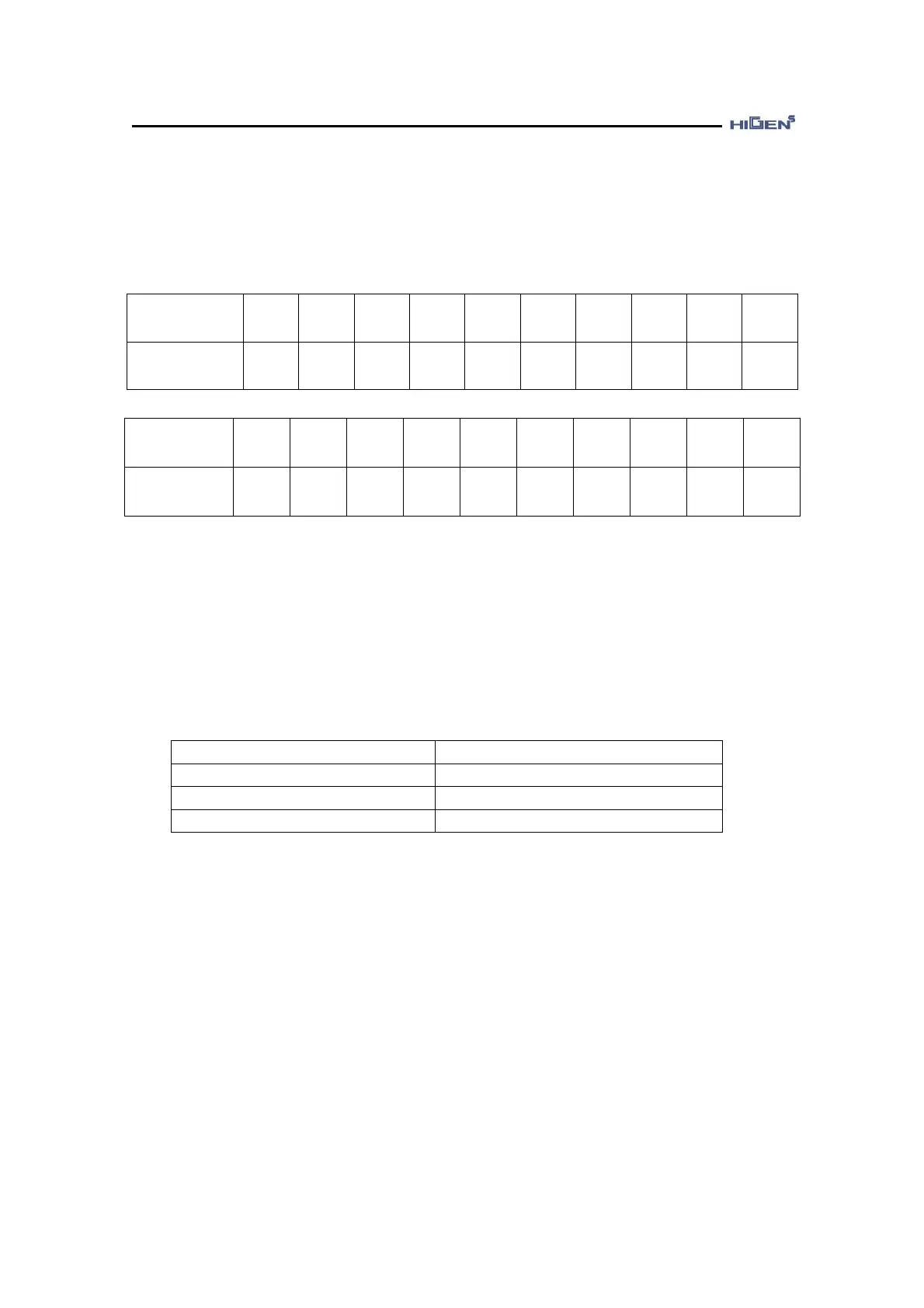

B. Checking Drive AMP-Type certainly.

AMP-Type

[ FDA70- ]

01 02

04/

04B

05 08 10

15/

15B

20/

20B

30/

30B

45

P01-11

[Drive ID]

1 2 4 5 8 10 15 20 30 45

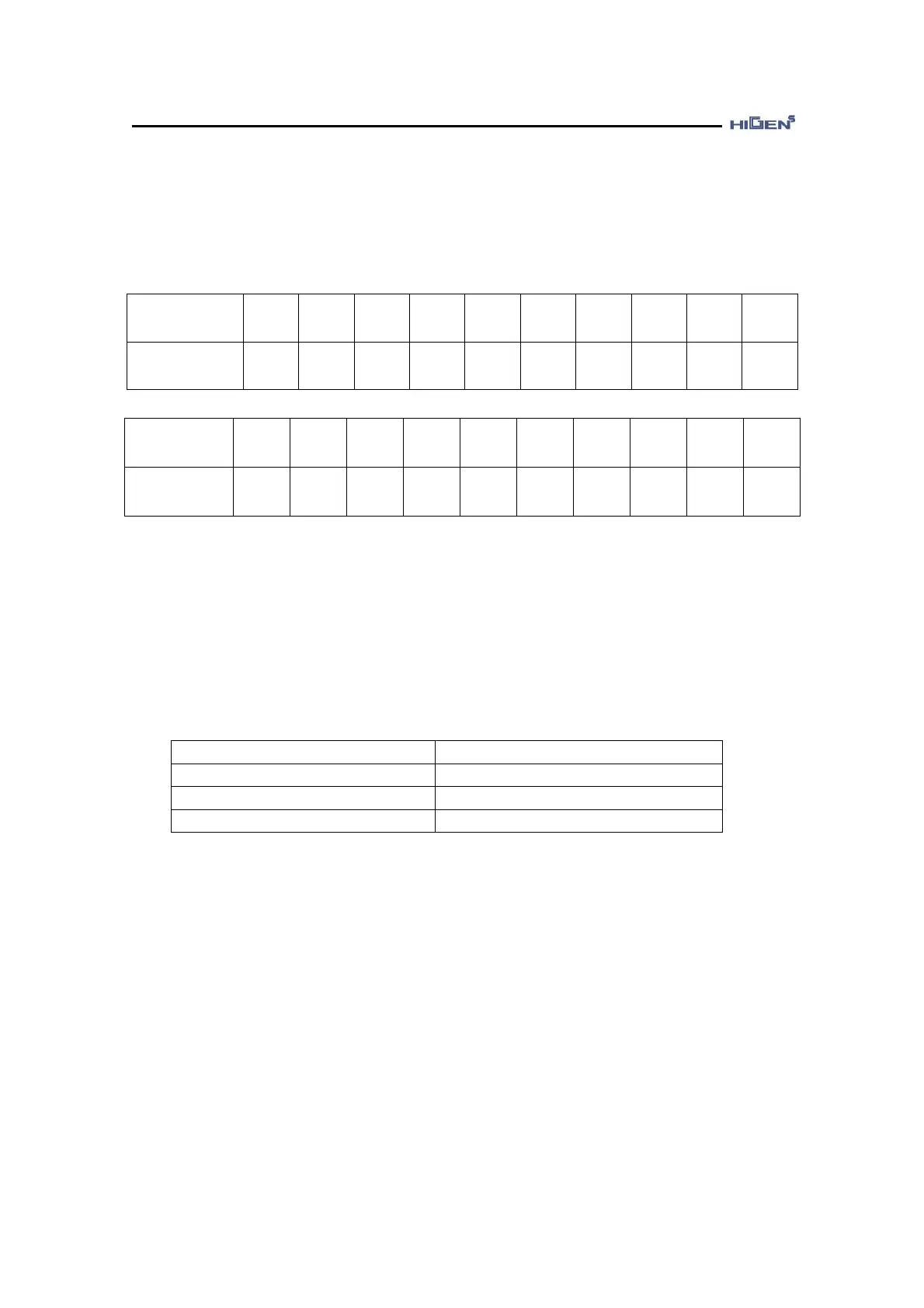

C. Checking Encoder ID certainly.

Encoder

Type

Manual

setting

INC

2000

INC

2500

INC

3000

INC

5000

INC

6000

INC

2048

ABS

11/

13bit

INC

17/

33bit

ABS

17/

33bit

P01-12

[Encoder ID]

Enc-0 Enc-A Enc-b Enc-C Enc-d Enc-E Enc-F Enc-G Enc-P Enc-R

♥ When you set the encoder ID to “Enc-0”, you can change the value of P01-13 (Encoder

pulse rate). But if you set the encoder ID to “Enc-A ~ Enc-R”, you cannot change the value of

P01-13.

D. Operate servo system after autotuning is off. (P02-17)

: Always cancel the autotuning during normal operation after gain setting using autotuning.

E. Motor handling

: Avoid impacting to the encoder in connecting coupling to the Motor shaft or operating.

F. Recommended specification of Encoder wiring.

Encoder type Page of wiring explanation

Incremental encoder 2-13

Absolute encoder 11bit 2-14

Absolute/Incremental encoder 17bit 2-15

G . Separate GND24 (CN1-24, 25) and GND (CN1-1, 8, 26, 33, 34, 36).

: When connect commonness, malfunction of servo drive and burnout can occur.

H . Treatment of the servo motor attached holding brake .

: The brake built in the servo motor is a normal closed type brake. Which is used only to hold

and can not be used for braking. Use the holding brake only to hold a stopped servo motor.

I. Do not supply AC at N, P connector when connect the power line to Small and

Medium capacity servo drive.

: If main power is DC power, because N connector (-) voltage and P connector (+) voltage,

burnout of servo drive when N, P connector is supplied AC power.

Choose positively necessary AC and DC power, and use.

Loading...

Loading...