22 English

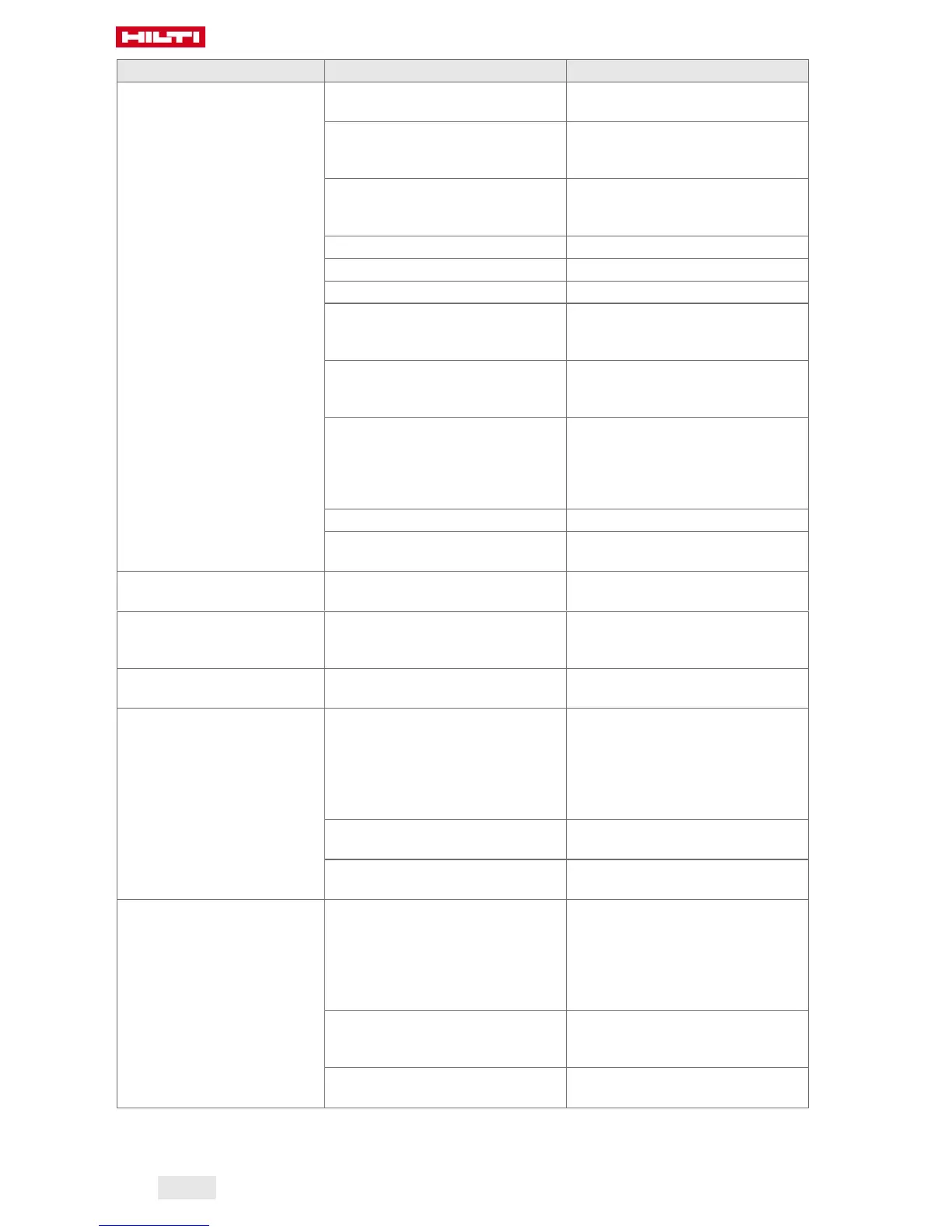

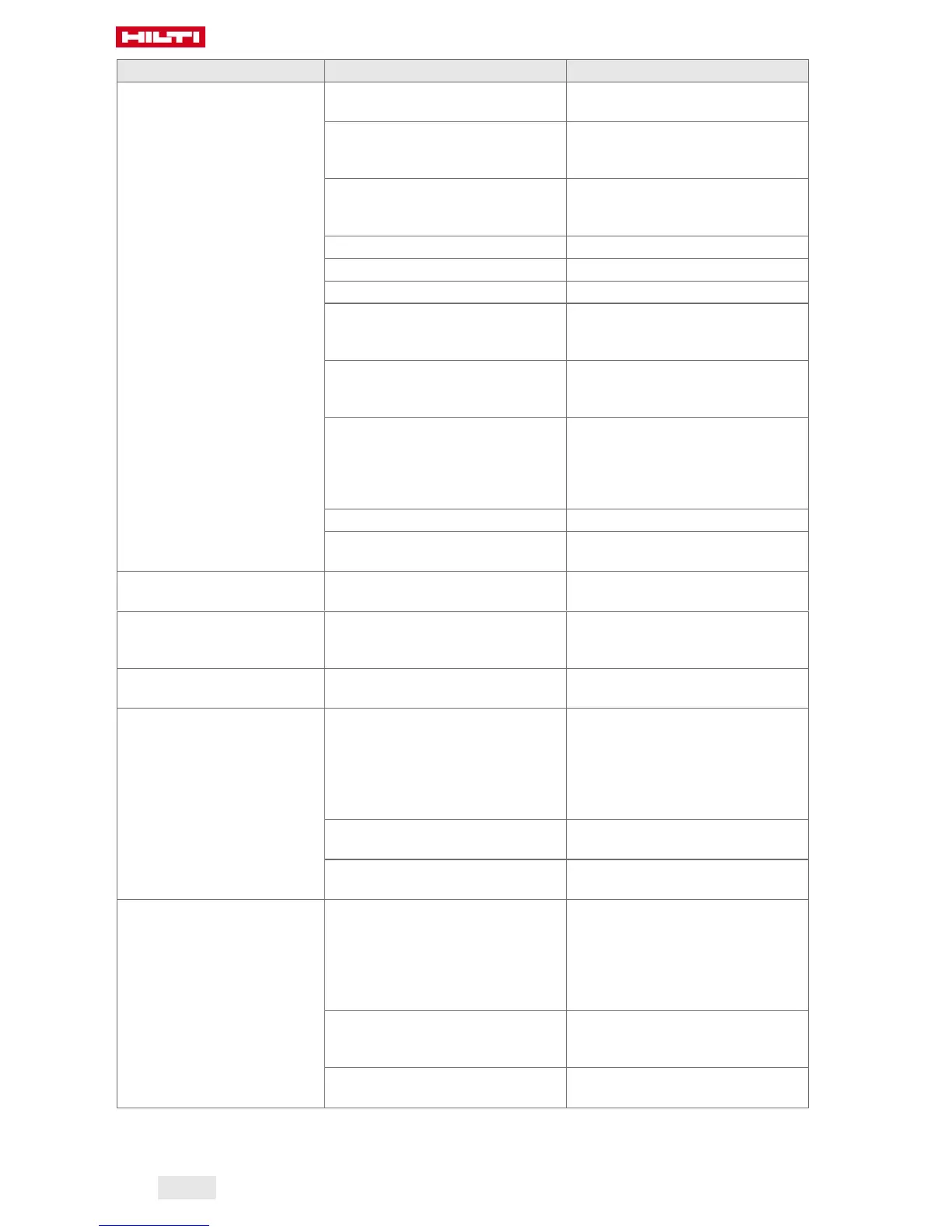

Malfunction Possible cause Action to be taken

The drilling speed is decreas-

ing.

Wrong core bit specification for the

base material.

▶ Select a more suitable diamond

core bit specification.

High steel content (indicated by

clear water containing metal cut-

tings).

▶ Select a more suitable diamond

core bit specification.

The diamond core bit is defective. ▶ Check the diamond core bit

for damage and replace it if

necessary.

Wrong gear selected. ▶ Select the right gear.

Contact pressure is too low. ▶ Increase the contact pressure.

The machine has too little power. ▶ Select the next lower gear.

The diamond core bit is polished. ▶ Sharpen the diamond core bit

by drilling into a sharpening

plate.

The water flow rate is too high. ▶ Reduce the water flow rate

by adjusting the water flow

regulator.

The water flow rate is too low. ▶ Check the water supply to

the diamond core bit or,

respectively, increase the water

flow by adjusting the water flow

regulator.

The brake has been applied. ▶ Release the brake.

Safety clutch disengages too soon

or is slipping.

▶ Have the machine repaired by

Hilti Service.

The handwheel can be turned

without resistance.

The split pin is broken. ▶ Replace the split pin.

The diamond core bit can’t be

fitted into the chuck.

The core bit connection end or

chuck is dirty or damaged.

▶ Clean and grease the connec-

tion end and/or the chuck or

replace these parts.

Water escapes at the water

swivel or gear housing.

The water pressure is too high. ▶ Reduce the water pressure.

Water escapes from the

chuck during operation.

The diamond core bit isn’t securely

tightened in the chuck.

▶ Tighten the diamond core bit

securely.

▶ Remove the core bit. Rotate the

diamond core bit approx. 90°

about its own axis. Refit the

diamond core bit.

The core bit connection end /

chuck is dirty.

▶ Clean and grease the connec-

tion end and/or the chuck.

The seal at the chuck or at the

connection end is defective.

▶ Check the seal and replace it if

necessary.

The drilling system has too

much play.

The diamond core bit isn’t securely

tightened in the chuck.

▶ Tighten the diamond core bit

securely.

▶ Remove the core bit. Rotate the

diamond core bit approx. 90°

about its own axis. Refit the

diamond core bit.

The core bit connection end /

chuck is defective.

▶ Check the connection end and

chuck and replace them if

necessary.

The carriage has too much play. ▶ Adjust the play between the rail

and carriage. → page 19

Printed: 24.05.2018 | Doc-Nr: PUB / 5431649 / 000 / 00

Loading...

Loading...