Auto-tuning for Sensorless Vector Control

Operations

and Monitoring

4–32

If the desired characteristic cannot be obtained in sensorless vector controlled operation

with standard (factory default) or auto-tuning data, adjust the motor constant(s)

according to the observed symptoms shown below.

Note 1:

If the inverter is using sensorless vector control and the motor is more than one frame size

smaller than the maximum applicable motor, then the motor characteristic values may not be

satisfactory.

Note 2:

No sensorless vector control operation is possible if two or more motors are connected (parallel

operation).

Note 3:

When the auto-tuning function is executed in the state that the DC braking is set, the motor

constants will not be accurately set. Therefore, disable DC braking and then start the auto-

tuning procedure again.

Note 4:

When accelerating or speeding up is not to be performed in the auto-tuning step for accelerating

up to 80% of the base frequency, lower the set value of manual torque boost.

Note 5:

Be sure the motor is stopped before you carry out an auto-tuning procedure. Auto-tuning data

which is derived while the motor is still running may not be correct.

Note 6:

Do not interrupt an auto-tuning procedure by removing power or by using the Stop command,

unless it is emergency. If this does occur, initialize the inverter’s parameters to the factory

default settings (see page 6–8). Then reprogram the parameters unique to your application, and

initiate the auto-tuning procedure again.

NOTE:

When the data of the H Group parameters does not match that of the motor,

satisfactory characteristics may not be obtained during sensorless vector operation. Also,

the stabilization adjustment (H06) is effective for V/F settings (00 and 01). The full

performance may not be achieved if the rating of a motor used is more than one frame

size smaller than the maximum applicable rating when the sensorless vector function is

used. You must disable sensorless vector operation when two or more motors are

connected. For the motor stabilization, set this data properly for the H03 (H203) param-

eter according to the motor used if its rating is not the same as the maximum applicable

rating in V/F operation.

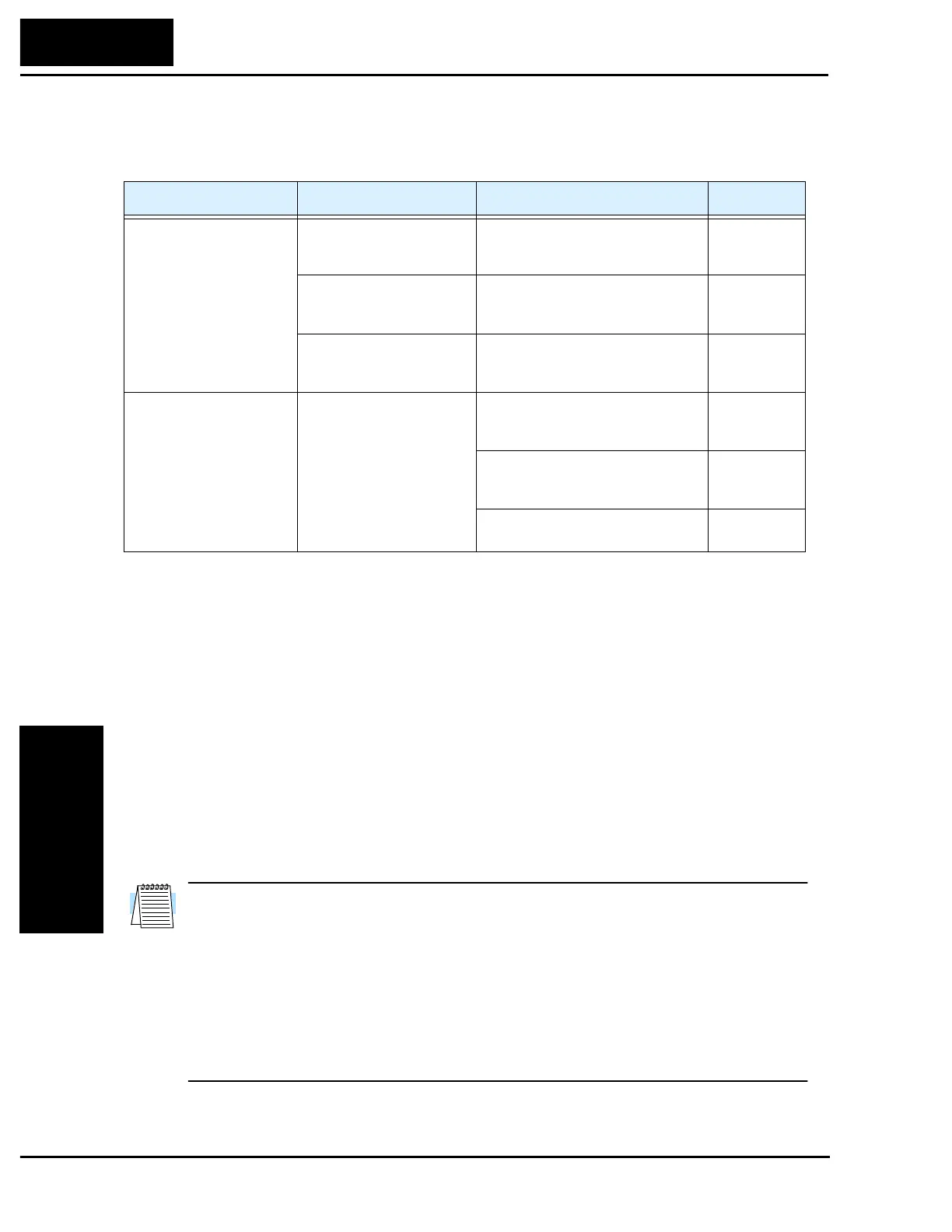

Operation Status Symptom Adjustment Parameter

Powered running

(status with an accelerating

torque)

When low frequency (a few

Hz) torque is insufficient

Increase the motor speed constant R1

in relation to auto-tuning data, step by

step, within 1 to 1.2 times R2.

H20 / H30 /

H220/ H230

When the speed fluctuation

coefficient becomes

negative

Increase the motor constant R2 in

relation to auto-tuning data, step by

step, within 1 to 1.2 times R2.

H21 / H32 /

H221 / H231

When the speed fluctuation

coefficient becomes positive

Decrease the motor constant R2 in

relation to auto-tuning data, step by

step, within 0.8 to 1 times R2.

H21 / H32 /

H221 / H231

Regeneration

(status with a decelerating

torque)

When low frequency (a few

Hz) torque is insufficient

Increase the motor speed constant R1

in relation to auto-tuning data, step by

step, within 1 to 1.2 times R1.

H20 / H30 /

H220/ H230

Increase the motor constant R2 in

relation to auto-tuning data, step by

step, within 1 to 1.2 times R2.

H21 / H32 /

H221 / H231

Decrease the carrier frequency set

value.

B83

Loading...

Loading...