[1] Overview

This engineering note applies when using SLV , 0-SLV and V2 (closed loop) control. It is often difficult to

get optimized motor performance because many parameters interact. Please refer to this document for

getting a rough idea how to achieve good motor performance with above control modes. Please also note that

the performance WILL NOT BE like a servo drive even in the case of V2 mode.

There are 3 basic modes with which you can get high torque performance with the SJ300 inverter:

(1) SLV control (No SJ-FB is used)

High motor torque performance with open loop can be obtained in the low frequency range (~0.5Hz).

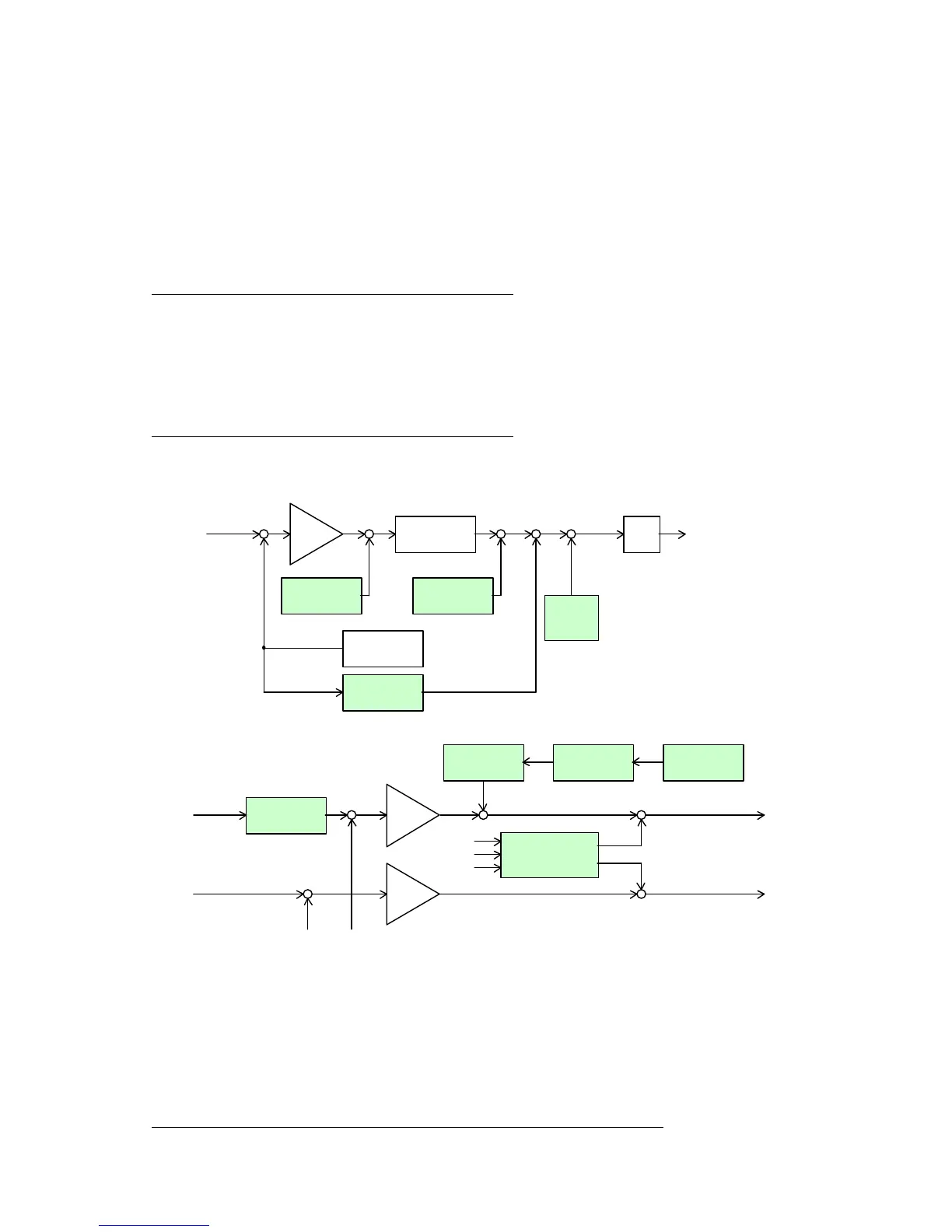

Please refer to a standard SLV block diagram in Fig 1 (section 2-2).

[H***] parameters are mainly adjusted for the control.

(2) 0-SLV control (No SJ-FB is used)

High torque performance can be obtained at around 0Hz. This does NOT mean the motor shaft will be at a

standstill. The motor rotates slightly to generate motor torque, since this is not a servo drive. Depending on the

application and tuning, you may be able to get full torque with the motor at standstill. This control algorithm is

different from SLV control.

[H***] parameters are mainly adjusted for the control.

ΠFrequency control block portion

• Voltage control block portion

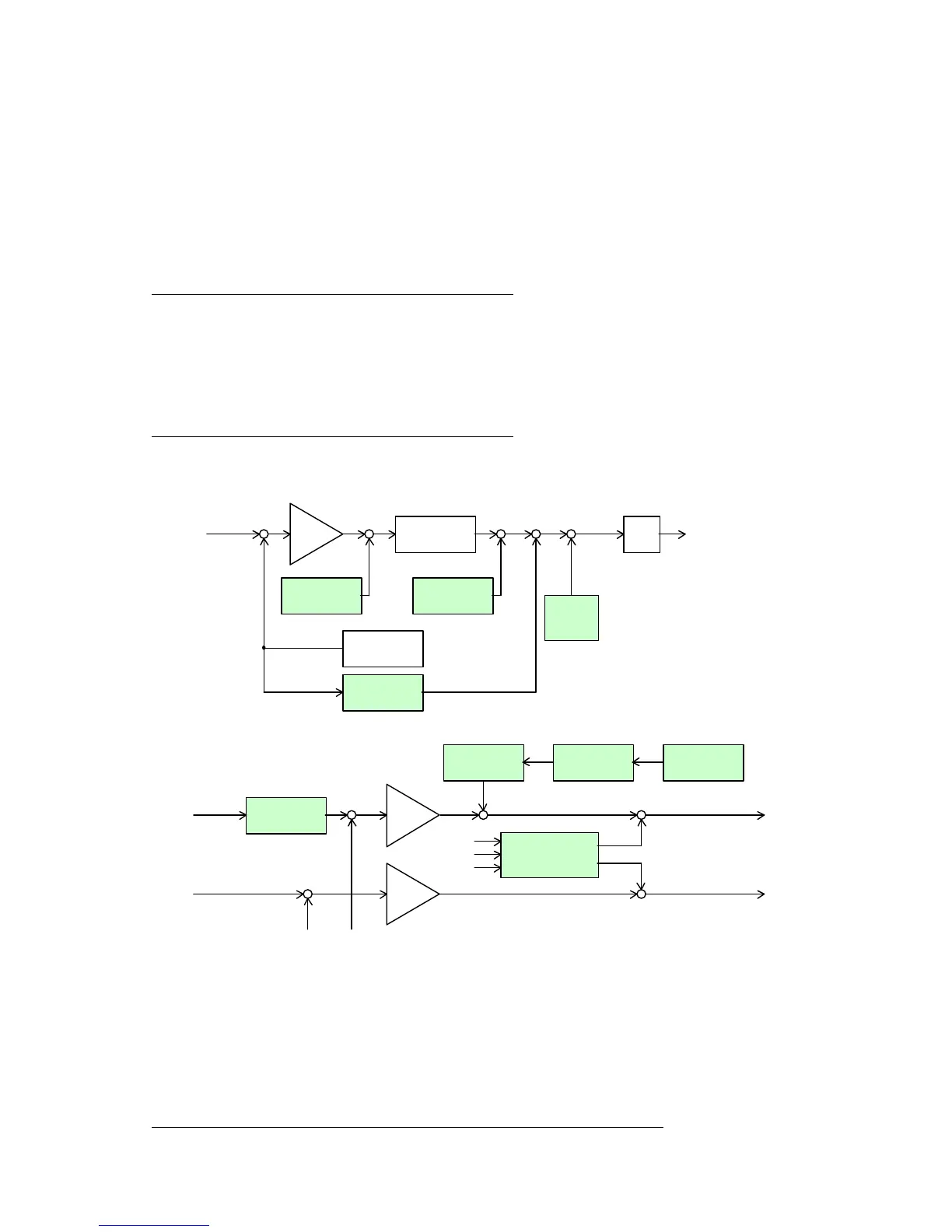

(3) V2 control (SJ-FB is used)

High torque and stable, accurate motor performance can be achieved with the SJ300 in vector mode.

A motor encoder and a feedback option card for SJ300 (SJ-FB) are needed to use this control mode.

There are two regulation modes within the V2 control mode: ASR mode and APR mode .

ΠASR mode : Inverter is controlled by speed command input (digitally set, analog input, or RS485)

• APR mode : Inverter is controlled by pulse train input signal

[H***] and [P***] parameters are adjusted for achieving good motor control.

A suitable mode should be selected depending on the application.

Loading...

Loading...