9

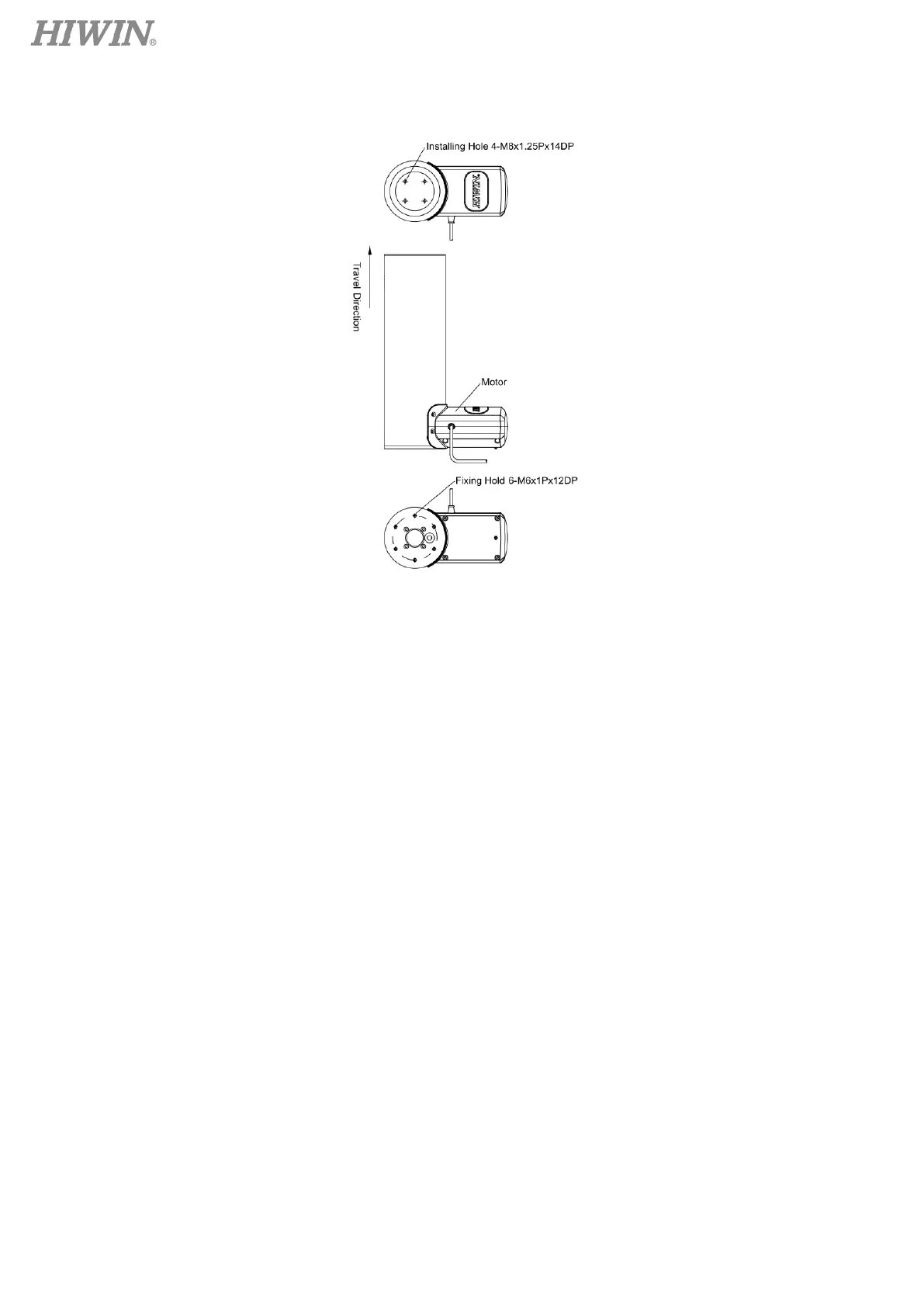

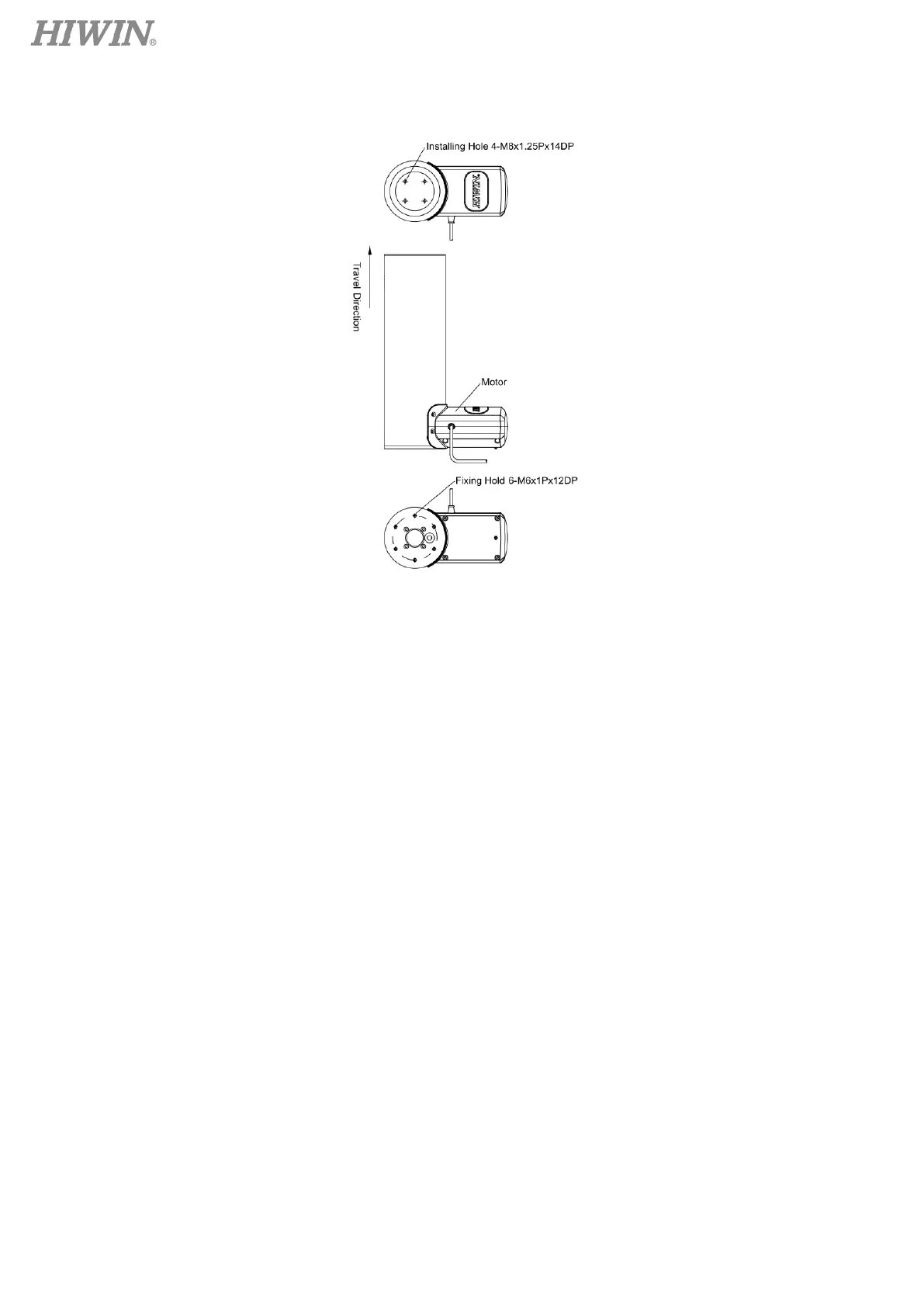

2.1.3 LAC1 Installation

2.2 The front and end joints of the linear actuator should be mounted onto two fixed positions on the main

chassis. Locations of these fixed positions should be chosen according to the stroke length of the linear

actuator (Users must be cautious that the two-way movement of linear actuator must be smooth and within

the stroke length after installed onto the fixed positions). Please ensure that no obstacle exists along the

travel path of the actuator.

2.3 After the fixed positions have been selected, install the fixtures onto these selected positions of the main

chassis. These fixtures are used to fix the front and end joints of linear actuator to the chassis.

2.4 Assemble the front and end joints of the linear actuator onto the two fixtures using fixture bolts. Please

ensure that the fixture bolts are able to rotate freely after this step is completed. On the other hand, users

should also make sure that the fixture bolts would not drop off either during operating or resting period.

2.5 The chassis of linear actuator should be fixed in the horizontal direction if it is going to be operated in this

direction and likewise for vertical operation.

2.6 The operation of the linear actuator should be tested manually after the installation is completed. Users

should make sure that:

The travel distance of the actuator is matching the requirement of the structural design.

The upper and lower limit switches are operated normally.

The motor stops when the extension tube reaches upper and lower limit switch positions.

If the linear actuator fails to meet any of these conditions, please repeat steps 2.2 to 2.4 until the above

mentioned clauses are met

Loading...

Loading...