28

06.2019

8.2 Lubrication

Operating manual

Centrifugal fans

HF R | RV | MRV

www.hlu.eu

The lubrication points of the fans have to be greased regularly using appropriated lubrication

tools. The lubrication periods depend on the operating hours of the fan (see next schedule).

J The bearings of the installed maintenance-free electric motors have a grease lling, which

is calculated for a service life of approx. 10.000 - 20.000 operating hours. The maintenan-

ce-free ange double bearings (299 T ...W, 399 T ...W), were lled with grease suciently

by the manufacturers, this means they have a calculated service life of approx. 20000 ope-

rating hours.

J The periods and amount of the lubrication on the electric motor and regreasable double

ange bearings 399T…N and block bearing 32T…ER depend on the operating hours of the

fan. After max. 8000 operating hours at the latest after one year of operation the bearings

have to be greased again according to the next schedule.

J We recommend as appropriated bearing grease a lithium soap grease, for example Shell-Al-

vania 2 or 3. The determined lubrication intervals are applicable to bearings in horizontal

mounting position at a maximum temperature of 70 °C. As lubricant aging is accelerated

at higher temperatures, the lubrication interval must be reduced by half with a temperature

increase of 15 °C.

J Concerning the lubrication intervals of electric motors please note the operating and main-

tenance instructions of the engine producer.

Details about the kind, amount and period of lubrication of the single

purchase component devices have to be taken from the external ma-

nufacturer’s operating manual.

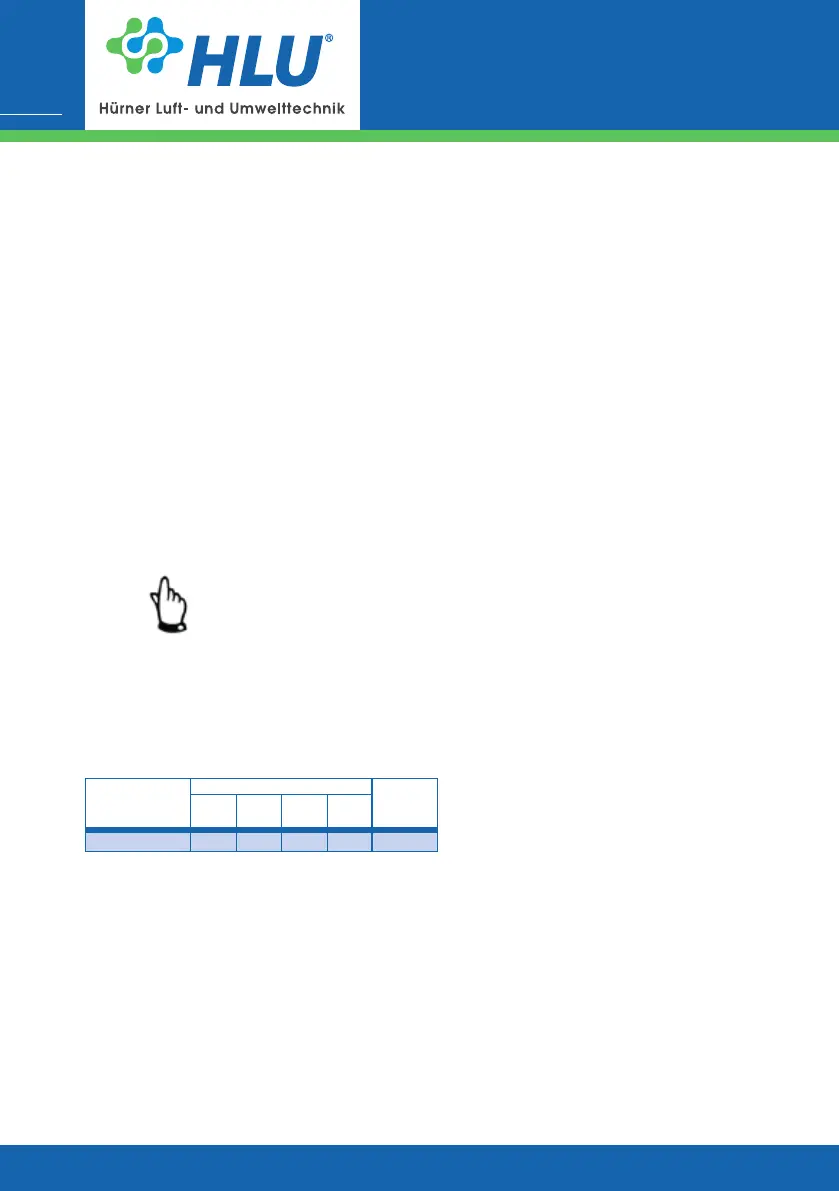

Greasing periods depending on the speed and nominal size of the fan:

Nominal fan

size

Speed fan

Quantity

of grea-

sing

2000

min-1

2500

min-1

3000

min-1

3500

min-1

HF R 250-17

8000 h 7000 h 5500 h 4500 h

8 g

Only the fan type HF R 250-17 R with a speed over 2000 min-1 has got a regreasable bearing

installed.

HF R ...-15 / 17 D / R

Loading...

Loading...