– 6 –

LOCATION

Before nalizing the location, make sure that consideration has been given for the

electrical conduit, water supply, drain connection, venting (if applicable), tabling (if needed),

chemical feeder replenishment (if applicable) and adequate clearance for opening the door.

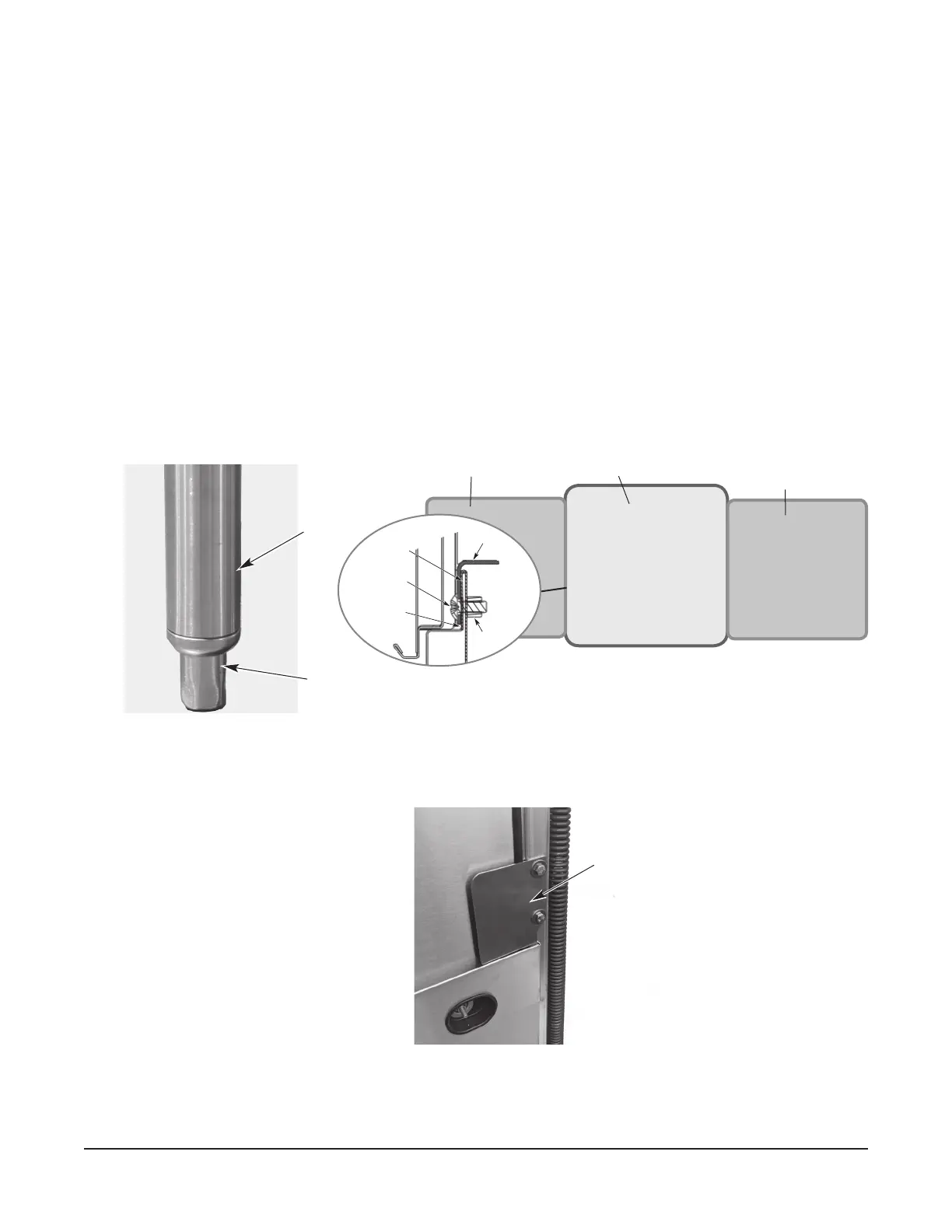

The dishwasher must be level before any connections are made. Turn the threaded feet

(Fig. 1) as required to level the machine and adjust to the desired height.

The edge of dish table that overhangs the AM16 wash tank should be turned down and

tted over the top of the dishwasher tank (Fig. 2). Apply an NSF approved sealant between

the overhang of the dish table and the inner wall of the wash tank to prevent leakage (Fig.

2). Fasten the dish tables to the inner wall of the wash tank with non-rusting truss head

screws or rivets (Fig. 2).

For straight-through installations, 30" clearance at the front and 15" clearance at the right

side by 29-1/2" clearance above the nished oor must be provided for service.

For machines equipped with ASR, 30" clearance at the front and 24" clearance at the right

side (or left if ASR is relocated to left side) by 33" clearance above the nished oor must be

provided for service. If ASR is relocated to left side, then 15" clearance is required at right side.

NOTE: For 480-volt units, 20" clearance required at left side.

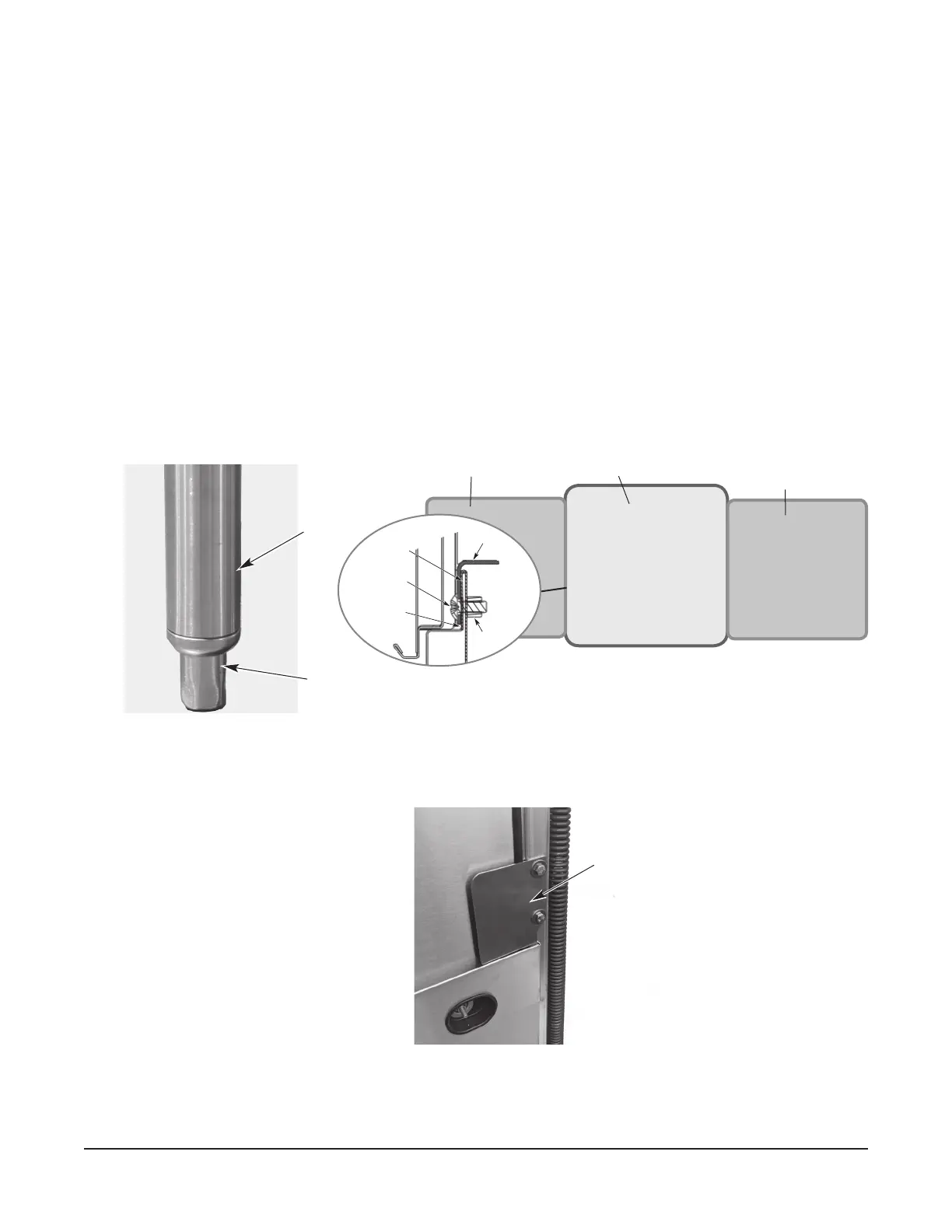

Based on dish table design, rear table brackets (Fig. 3) may need to be adjusted or removed.

Loosen the two bolts and nuts and adjust or remove as required.

NOTE: For AM16-ASR, AM16T-ASR, AM16VL-ADV, AM16VLT-ADV and AM16-SVLT

models, the ASR module may be relocated to the left side of the machine using service kit

part number 00-950446 or sales accessory kit ASRLEFTKIT-AM16.

Fig. 1

Fig. 2

MACHINE

LEG

ADJUSTABLE

FOOT

WASH TANK

DISH TABLE

DISH TABLE

STRAIGHT-THROUGH OPERATION SHOWN

DISH TABLE

NUT

SEALANT

MACHINE SCREW

OR RIVET

INNER WALL OF

WASH TANK

Fig. 3

REAR TABLE

BRACKET

Loading...

Loading...