C6097 · Edition 01.24

EN-2

2 CHECKING THE USAGE

Gas pressure switches C6097 for monitoring in-

creasing and decreasing gas or air pressure.

C6097A: switches with falling pressure,

C6097B: switches with rising pressure.

Positive pressure

Negative

pressure

C6097A

Gas, air, flue gas,

biogas

Air, flue gas

C6097B

Gas, air, flue gas,

biogas

Air, flue gas

This function is only guaranteed when used within

the specified limits– see page 6 (9 Technical

data). Any other use is considered as non-compliant.

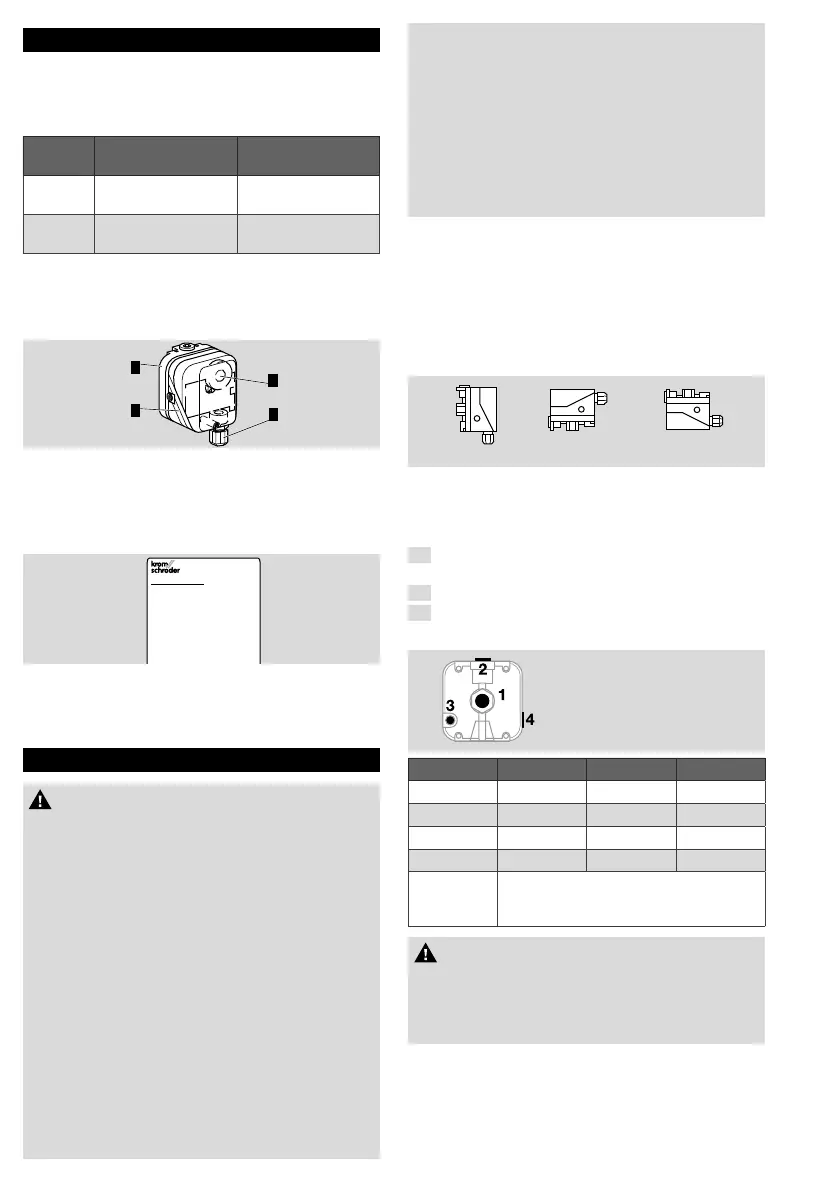

2.1 Part designations

1

2

3

4

1 Upper housing section with cover

2 Lower housing section

3 Hand wheel

4 M16 cable gland

2.2 Type label

C6097

CE

Made in Germany

Max. inlet pressure = withstand pressure, mains

voltage, ambient temperature, enclosure: see type

label.

3 INSTALLATION

CAUTION

Please observe the following to ensure that the

C6097 is not damaged during installation and

operation:

– Dropping the device can cause permanent

damage. In this event, replace the entire device

and associated modules before use.

– Use approved sealing material only.

– Continuous operation with gases containing

more than 0.1%-by-vol. H

2

S or ozone

concentrations exceeding 200µg/m

3

accelerate

the ageing of elastomer materials and reduce

the service life.

– Check max. ambient temperature– see page

6 (9 Technical data).

– When using silicone tubes, only use silicone

tubes which have been sufficiently cured.

– Vapours containing silicone can adversely affect

the functioning of electrical contacts.

– Condensation or vapours containing silicone

must not be allowed to get into the housing. At

subzero temperatures, malfunctions/failures due

to icing can occur.

– When installing outdoors, place the C6097 in a

roofed area and protect from direct sunlight

(even IP65 version).

– Avoid strong impact on the unit.

– In case of highly fluctuating pressures, install a

damping nozzle/restrictor orifice.

Installation position

➔ Installation position as required, preferably with

vertical diaphragm. Then the switching point p

S

corresponds to the scale value SK set on the

hand wheel. In other installation positions, the

switching pointp

S

will change and no longer cor-

respond to the scale valueSK set on the hand

wheel. Check the switching point.

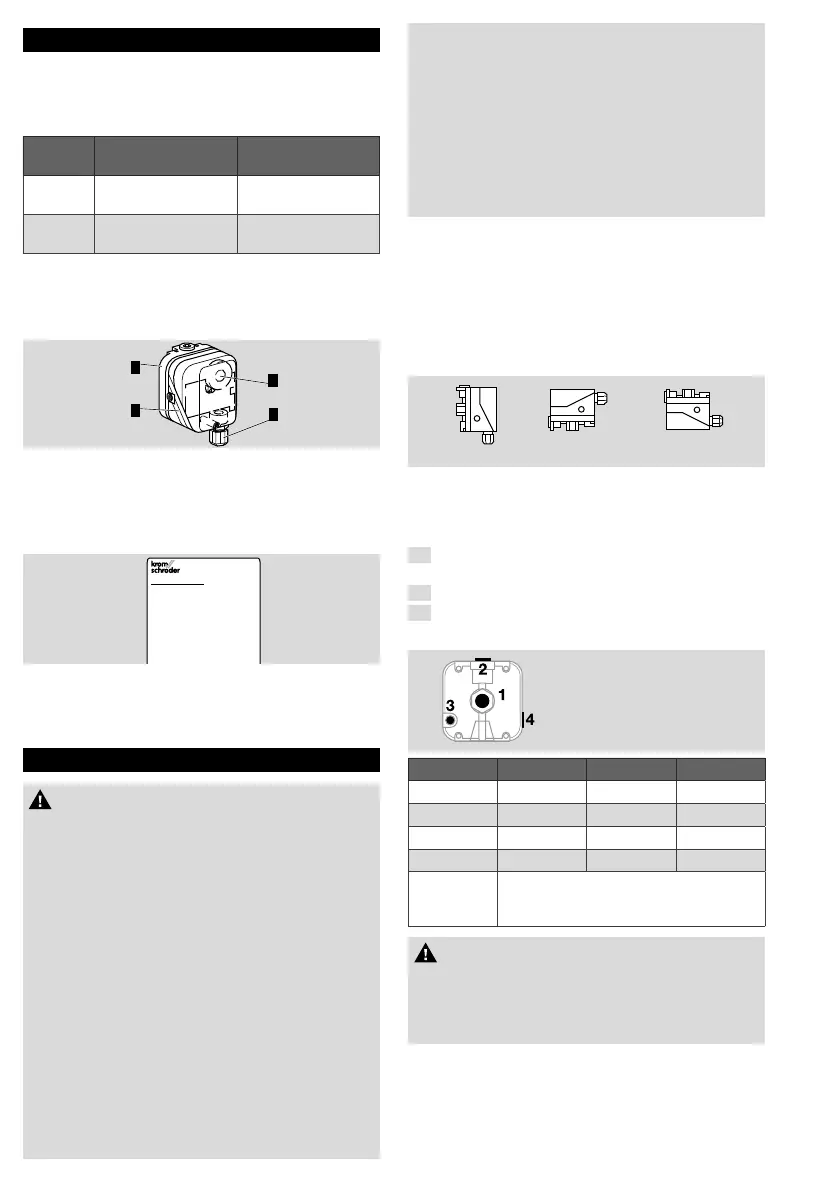

p

s

= SK p

s

= SK + 18 Pa p

s

= SK - 18 Pa

➔ The C6097 must not be in contact with masonry.

Minimum clearance 25mm (1").

➔ Ensure that there is sufficient installation space.

➔ Ensure unobstructed view of the hand wheel.

1

Disconnect the system from the electrical power

supply.

2

Close the gas supply.

3

Ensure that the pipeline is clean.

Ports

1 and 2

Positive Pressure (Rp ¼" )

3 and 4

Negative Pressure (Rp

1

/8 " )

Pressure Connect Seal Free

Positive 1 2 3 or 4

Positive 2 1 3 or 4

Negative 3 4 1 or 2

Negative 4 3 1 or 2

Differential

1 or 2 for higher absolute pressure.

3 or 4 for lower absolute pressure.

Seal the ports that are not in use.

CAUTION

Ports 3 and 4 are connected to the upper dia-

phragm chamber with the micro switch. For this

reason, pipes carrying gas must not be connected

to port 3 or 4.

➔ A filter pad at port 4 protects the electrical

contacts in the C6097 from dirt particles in the

surrounding air or in the medium.

Loading...

Loading...