C6097 · Edition 01.24

EN-3

4 WIRING

CAUTION

– To ensure that the C6097 is not damaged

during operation, note the switching capacity,

see page 6 (9 Technical data).

In the case of low switching capacities, such as

24V, 8mA, for example, we recommend using an

RCmodule (22Ω, 1μF) in air containing silicone or

oil.

1

Disconnect the system from the electrical power

supply.

2

3

4

5

M16 x 1,5:

6

Wire as shown on the connection diagram.

7

Tighten the M16 gland.

➔ Contacts 3 and 2 close when subject to in-

creasing pressure. Contacts 1 and 3 close when

subject to falling pressure.

COM

3

NC

1

NO

2

NO

2

NC

1

COM

3

L1

5 ADJUSTMENT

➔ The switching point is adjustable via hand wheel.

1

Disconnect the system from the electrical power

supply.

2

Unscrew the housing cover.

➔ Once the settings have been adjusted success-

fully, fit the housing cover again. Note the tight-

ening torques, see page 6 (9 Technical data).

3

Connect an ohmmeter.

COM

3

NC

1

NO

2

NO

2

NC

1

COM

3

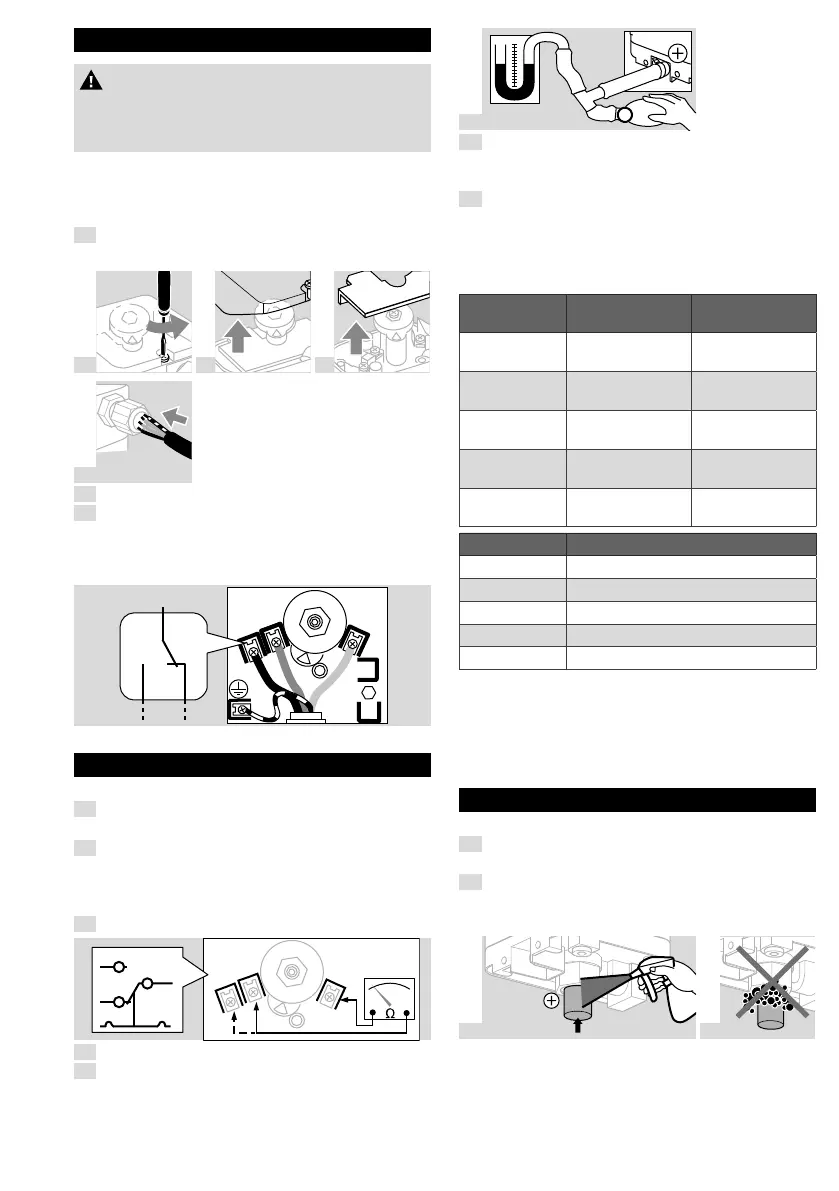

4

Set the switching point using the hand wheel.

5

Connect a pressure gauge.

6

0

1 cm = 1 mbar

7

Apply pressure. In doing so, monitor the

switching point on the ohmmeter and the

pressure gauge.

8

If the C6097 does not trip at the desired

switching point, correct the adjusting range

using the hand wheel. Relieve the pressure and

repeat the process.

5.1 Adjusting range

Type

Adjusting

range

1)

Switching

differential

2)

C6097A4010

40–600Pa

(0.4–6mbar)

20–30Pa

(0.2–0.3mbar)

C6097A4110

100–1000Pa

(1–10mbar)

25–40Pa

(0.25–0.4mbar)

C6097A4210

0.25–5 kPa

(2.5–50mbar)

0.08–0.15 kPa

(0.8–1.5mbar)

C6097A4310

3–15 kPa

(30–150mbar)

0.3–0.5 kPa

(3–5mbar)

C6097A4410

10–50 kPa

(100–500mbar)

0.8–1.7 kPa

(8–17mbar)

Type Max. inlet pressure p

max.

C6097A4010 10 kPa (100mbar)

C6097A4110 50 kPa (500mbar)

C6097A4210 50 kPa (500mbar)

C6097A4310 60 kPa (600mbar)

C6097A4410 60 kPa (600mbar)

1) Adjusting tolerance = ±15% of the scale value.

2) Mean switching differential at min. and max. setting.

➔ Deviation from the switching point during testing

pursuant to EN1854 Gas and air pressure

switches: ±15%.

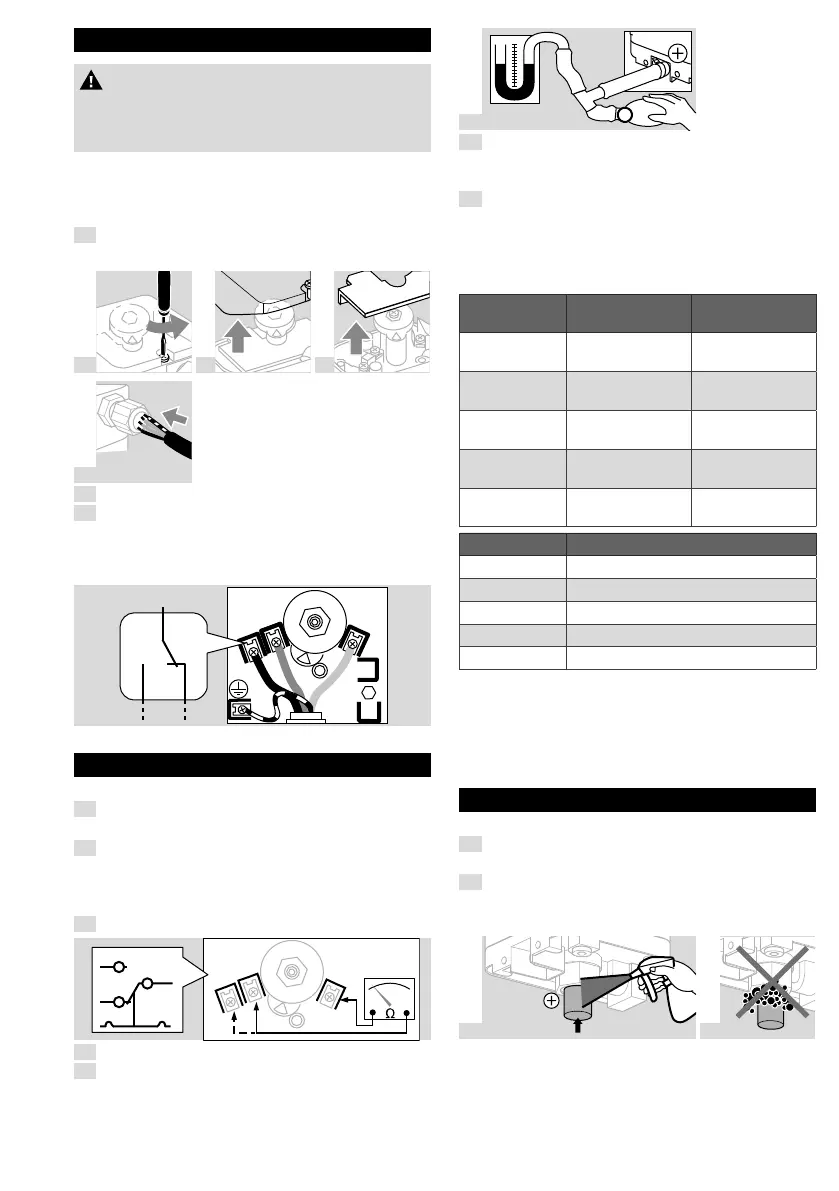

6 TIGHTNESS TEST

Check all gas ports used for tightness.

1

Shut off the downstream gas pipeline close to

the valve.

2

Open the valve and the gas supply.

➔ N

2

= 900mbar, max. 2bar (13psi, max. 29psi)

<15min.

3

N

2

4

Loading...

Loading...