C6097 · Edition 01.24

EN-6

9 TECHNICAL DATA

Gas type: natural gas, town gas, LPG (gaseous),

flue gas, biogas (max. 0.1%-by-vol. H

2

S) and air.

Electrical connection: screw terminals.

Diaphragm pressure switch, silicone-free.

Diaphragm: NBR.

Housing: glass fibre reinforced PBT plastic with low

gas release.

Lower housing section: AlSi 12.

Enclosure: IP65. Safety class: 1.

Storage temperature: -20 to +40°C (-4 to +104°F).

Long-term use in the upper ambient temperature

range accelerates the ageing of the elastomer ma-

terials and reduces the service life (please contact

manufacturer).

The set switching point may noticeably change

in media and ambient temperatures below -30°C

(-22°F).

Weight: 270 to 320 g (9.5 to 11.3 oz) depending on

equipment.

9.1 EU certified pressure switches

Max. inlet pressure p

max.

= withstand pressure, see

adjusting range, page 3 (5.1 Adjusting range).

Max. medium and ambient temperatures: -20 to

+80°C (-4 to +176°F).

Switching capacity:

U = 24–250VAC,

I = 0.05–5A at cos φ = 1,

I = 0.05–1A at cos φ = 0.6.

Line entrance:

M16x1.5 cable gland,

clamping range: diameters of 4 to 10mm,

Cable diameter: AWG24 to AWG13,

0.5 to 1.8mm (0.02 to 0.07").

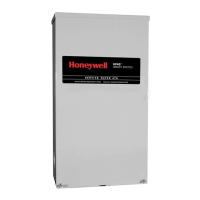

9.2 Recommended tightening torque

Component

Tightening

torque

[Ncm]

Cover screws 65

M16 x 1.5 cable gland 50

½" NPT conduit 170 (15 lb")

Rp 1/8 pipe connection on

aluminium lower section

250

Rp 1/4 connection (1/4" NPT) on

aluminium lower section

1300

Rp 1/8 connection on upper

housing section

250

Clamping terminal screws 80

T15 test point screw 150

10 DESIGNED LIFETIME

This information on the designed lifetime is based

on using the product in accordance with these

operating instructions. Once the designed lifetime

has been reached, safety-relevant products must be

replaced.

Designed lifetime (based on date of manufacture) in

accordance with EN13611, EN1854 for C6097:

Medium Designed lifetime

Switching

cycles

Time (years)

Gas 50,000 10

Air 250,000 10

You can find further explanations in the applicable

rules and regulations and on the afecor website

(www.afecor.org).

This procedure applies to heating systems. For ther-

moprocessing equipment, observe local regulations.

11 CERTIFICATION

11.1 Certificate download

Certificates – see www.docuthek.com

11.2 Declaration of conformity

We, the manufacturer, hereby declare that the prod-

ucts C6097 with product ID No. CE- 0085AP0467

comply with the requirements of the listed Directives

and Standards.

Directives:

– 2014/35/EU – LVD

– 2014/30/EU – EMC

– 2011/65/EU – RoHS II

– 2015/863/EU – RoHS III

Regulation:

– (EU) 2016/426 – GAR

Standards:

– EN13611:2015+AC:2016

– EN1854:2010

The relevant product corresponds to the tested type

sample.

The production is subject to the surveillance proce-

dure pursuant to Regulation (EU) 2016/426 AnnexIII

paragraph3.

Elster GmbH

11.3 UKCA certified

Gas Appliances (Product Safety and Metrology etc.

(Amendment etc.) (EU Exit) Regulations 2019)

BS EN13611:2015+AC:2016, BS EN1854:2010

Loading...

Loading...