ENI7003R8 KO65 2013

SETTING THE OPTIONAL FEATURES

1. Post-purge or no post-purge

Post-purge mode

(default for all DBC2000E

models): before going to standby after heat

demand has ended, the DBC2000E performs a

15s post-purge cycle to ventilate the burner

chamber, with the blower switched on and the

firing rate in low position to save energy.

No post-purge mode

(selectable option): the

DBC2000E goes to standby with the blower

switched off immediately after heat demand ends

and the firing rate goes to low position.

STD model:

To enable no post-purge, apply line voltage to

terminal 12 on the wiring base. Practically this

means that a jumper is placed between terminals

1 (L) and 12.

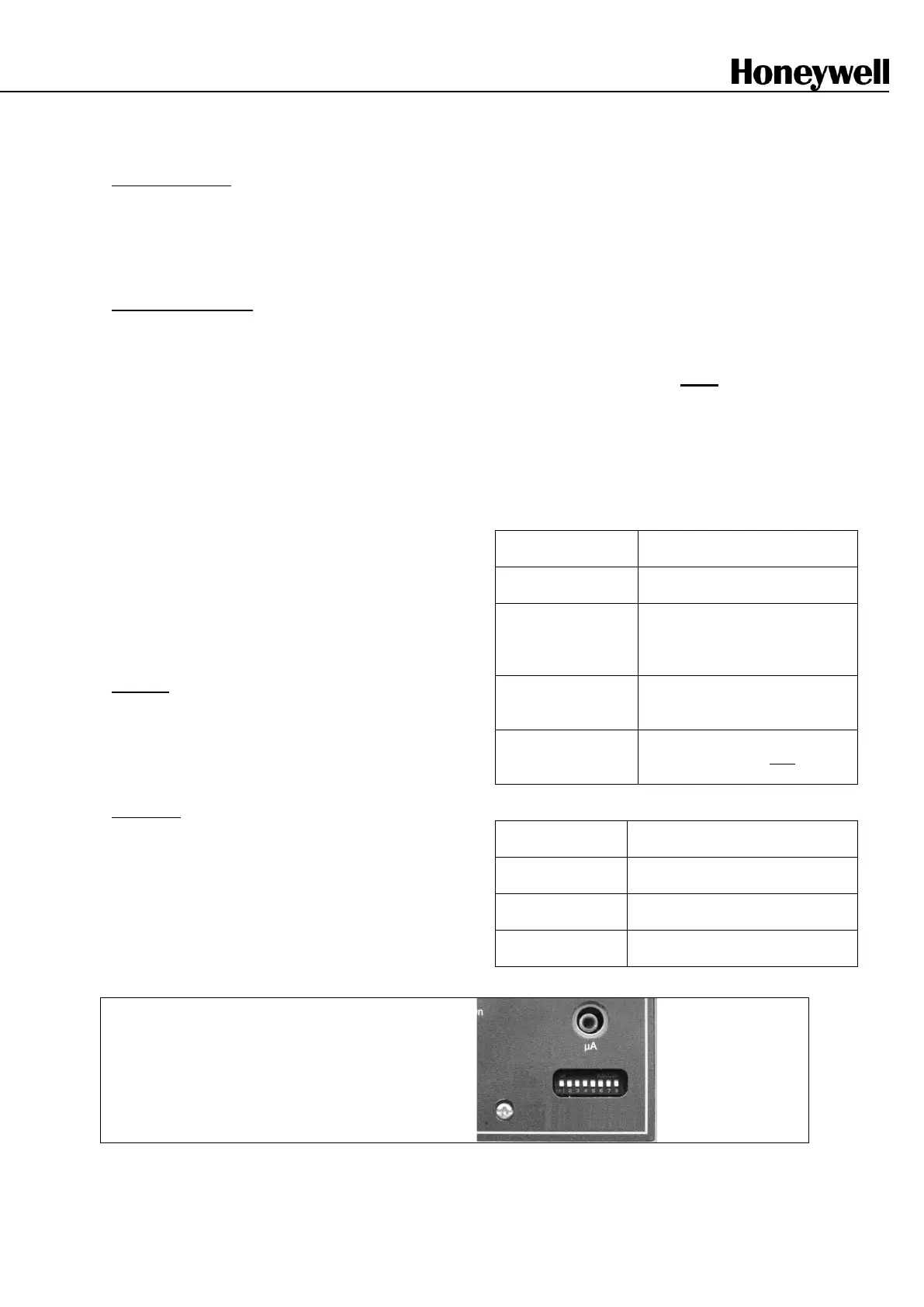

ENH/ULT models:

To enable no-post-purge, make the correct DIP-

switch setting on the front of the DBC2000E.

SW1 = POSTPURGE select.

Factory set to post-purge (SW1=off).

See fig. 4-5 to locate the DIP switches.

2. Pilot Ignition (PI) or Direct main

Burner Ignition (DBI)

PI mode

(default): the main burner is ignited

indirectly by using an interrupted or intermittent

pilot flame. After the pilot is ignited and

stabelized, the DBC2000E goes for a second trial

of ignition (2

nd

safety and main stabilization are

3s) to ignite the main burner.

DBI mode

(selectable option): the intermittent

pilot ignition cycle is used to ignite the main

burner directly via the spark igniter. The second

trial for ignition has become redundant in this

mode. In DBI mode the 2

nd

safety and main

stabilization times are 0s and DBC2000E goes

straight into running/modulate after pilot

stabilization.

STD model:

To enable DBI mode, apply line voltage to

terminal 22 on the wiring base. Practically this

means that a jumper is placed between terminals

1 (L) and 22.

ENH/ULT models:

To enable DBI mode, make the correct DIP-switch

setting on the front of the DBC2000E.

SW2 = DBI/PI select. Factory set to PI (SW2=off).

See fig. 4-5 to locate the DIP switches.

3. Valve Proofing System – VPS

(ENH/ULT models only

)

Connect a gas pressure switch (such as the

C6097A2210) to terminal 22 on the wiring base

(N.O. contact).

Rule of thumb: adjust the pressure switch to 0.5x

the inlet pressure.

Table 5: VPS function:

VPS is not used (default)

SW4 = on

SW5 = off

performed during pre-purge

cycle, right after the heat

SW4 = off

performed right after the heat

SW4 = on

performed before and after

Table 6: VPS timing:

VPS test time

10s (default)

SW 1: Post-purge use (default: off = post-purge enabled)

SW2: DBI/PI select

(default: off = PI enabled)

SW3: VPS use

(default: off = disabled)

SW4: VPS pre-config

(default: off = disabled)

SW5: VPS post-config

(default: off = disabled)

SW6: VPS test time

(default: off = see timing table)

SW7: VPS test time

(default: off = see timing table)

SW8: Not used (for future use)

Fig 4-5 Configuration DIP switches (VPS) on the front of the DBC2000E (ENH/ULT only)

Loading...

Loading...