F57A,B FLUSH-MOUNT COMMERCIAL ELECTRONIC AIR CLEANER

68-0083—07 10

Air Vent

The air vent helps to control gaseous contaminants such

as by-products of cigarette smoking by allowing some of

the air circulated through the F57 to be discharged into the

return plenum.

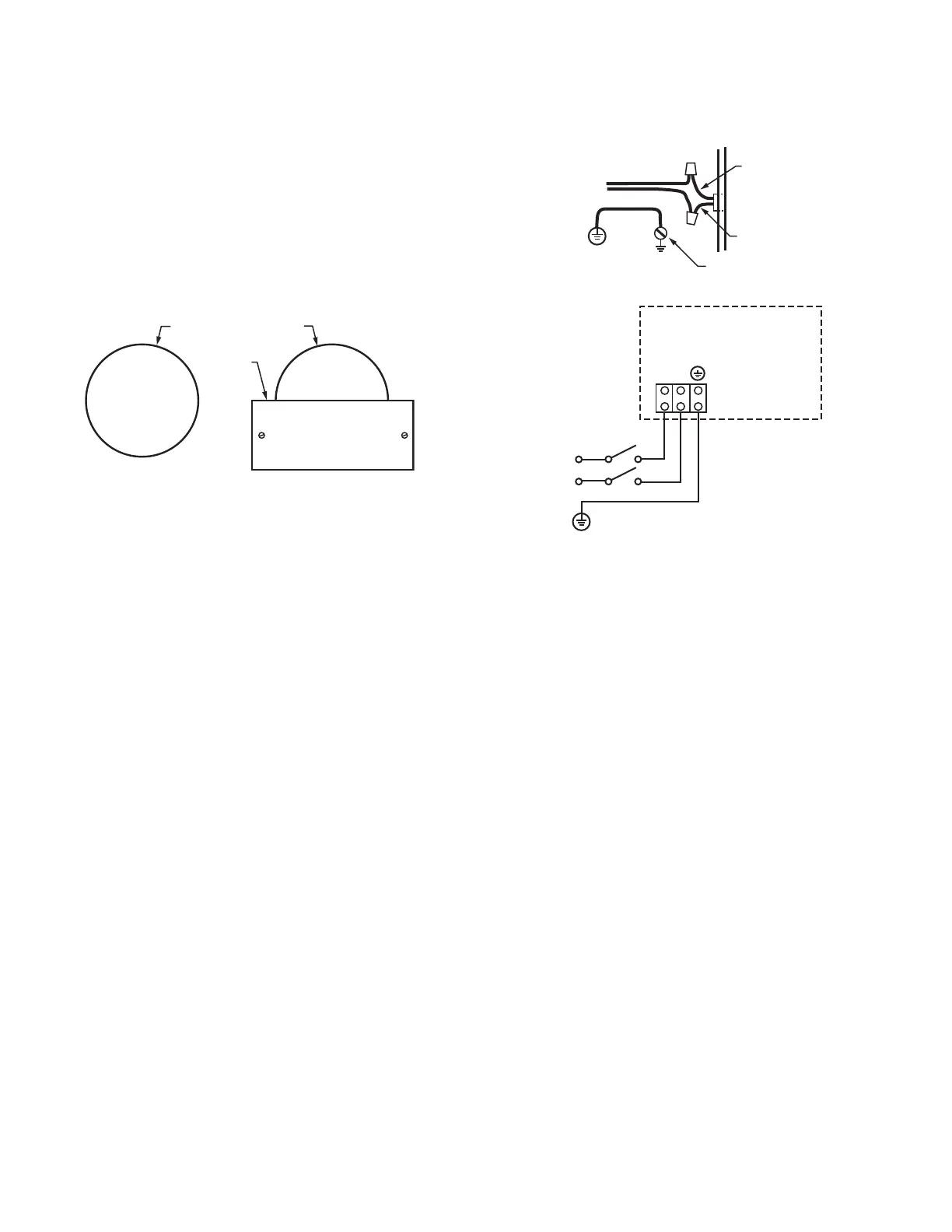

To use the air vent, remove the five inch knockout in the

side of the F57 cabinet. See Fig. 7. When venting into the

false ceiling cavity, leave the vent fully open. When ducting

into the return plenum, install damper and position it to

reduce the opening by 50 percent.

Fig. 7. Air vent adjustment.

Wiring

IMPORTANT

Before wiring the F57, remove the power supply

cover. After completing the wiring procedures, reat-

tach the power supply cover.

All wiring must comply with applicable codes and

ordinances.

Power supply wiring system shall provide disconnect

switch for all poles.

The power source to the F57A,B must agree with the model

type, either 120 Va.c., 60 Hz or 220.240 Va.c., 50 Hz.

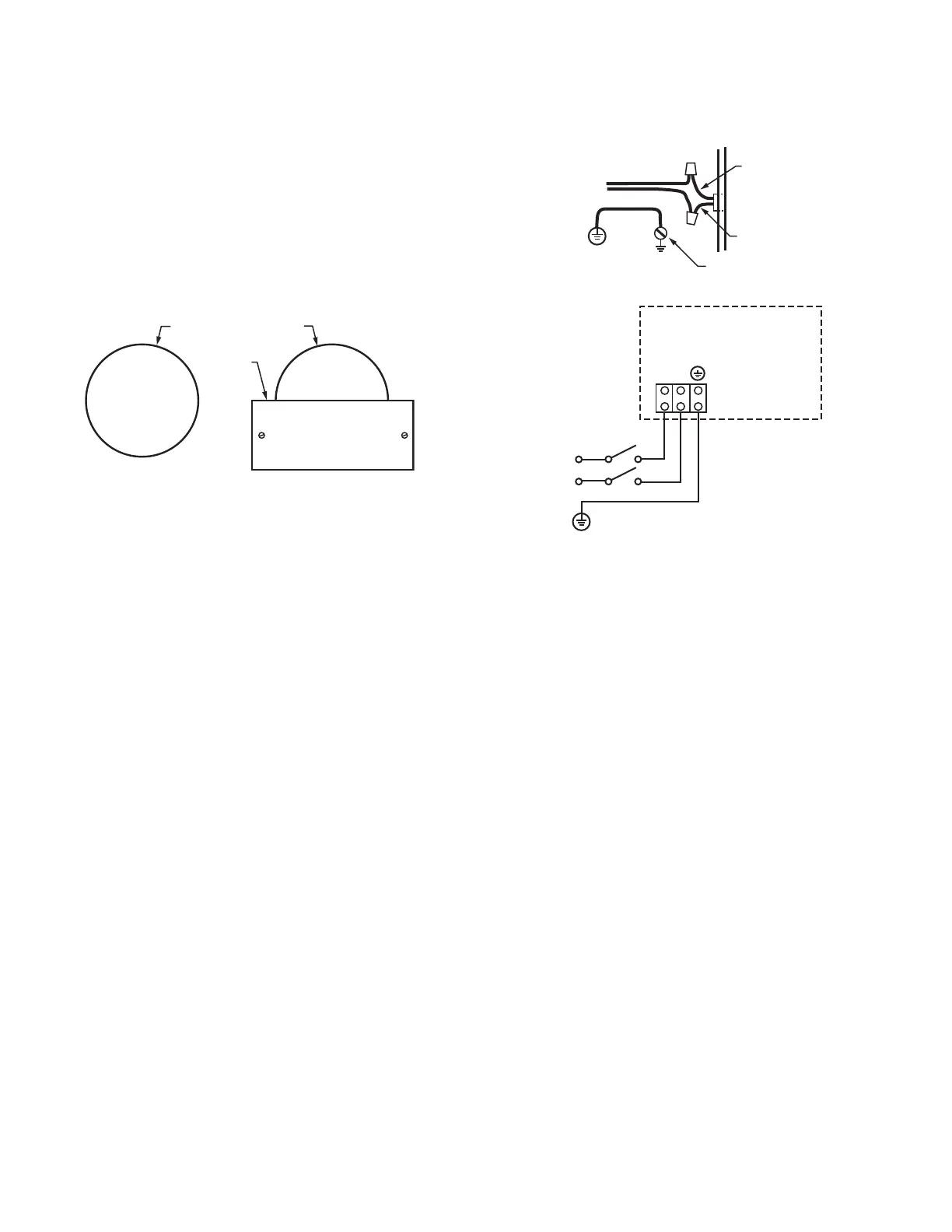

To wire 120 Va.c., 60 Hz model:

Run three No. 14 color-coded wires through the conduit

to the wiring compartment of the F57. Attach the green

wire to the external ground. The black and white wires

are the power carriers.

Attach the conduit to the knockout desired (either the

large or small knockout).

Attach the green ground wire to the ground screw.

Ground the F57 for proper operation and safety.

Attach the black and white wires to the black and white

wires from the F57 using the wire nuts. See Fig. 8.

To wire 220.240 Va.c., 50 Hz model, see Fig. 8.

IMPORTANT

Earth (ground) the F57 for proper operation and

safety.

This appliance incorporates an earth connection for

functional purposes only.

Fig. 8. Typical F57 wiring hookups.

Reassemble the F57

Reinstall the electronic cells, prefilter, charcoal filter (if

used) and grille assembly. For proper installation of the

cells, see “Service” on page 11.

CHECKOUT

Inspect the Installation

Refer to Fig. 9 and 10 for location of components.

Be sure that the screws on the back of the F57 are

removed to allow for the motor floating suspension.

Observe that the F57 is oriented for good air circulation.

Check that the F57 is correctly and securely attached.

Be sure that the F57 weight does not overstress the

suspended ceiling.

Make sure that the access door is easily opened, and

that the prefilter, cells, and activated carbon filters (if

used) are secure within the unit.

Check leveling of the F57. If necessary, further reinforce

and relevel suspended ceiling T-bar grid and adjust the

hanging wires. If unit is not level, motor can be noisy or

can eventually malfunction.

Check that the electronic cells are correctly oriented for

correct airflow. The cells are correctly oriented when the

contact board of the cell is properly seated. The ionizer

section faces the access door and the collector section

faces the fan.

Be sure the prefilter is correctly placed. The airflow

arrow on the prefilter should be pointing toward the

cells.

Check that the wiring compartment cover is correctly

reinstalled and the grille assembly is latched closed.

Clean the inside and outside of the F57.

KNOCKOUT KNOCKOUT

FIELD SUPPLIED

DAMPER

M7640

120V A.C., 60 HZ MODEL

BLACK FROM F57

WHITE FROM F57

BLACK

WHITE

120V A.C.

F57 GROUND SCREW

220-240V A.C., 50 HZ MODEL

F57A / F57B

N

N

L

L

220-240V A.C.

M5669B

Loading...

Loading...