ELSTER RABO

®

Rotary Gas Meter 10 Honeywell

RABO

®

Rotary Gas Meter 09 Elster Instromet

3. Pull off the index cover.

• It helps to rock it slightly.

• Be careful not to damage the masking plate and

index when removing the cover.

4. Carefully pull off the index masking plate [Figure 12].

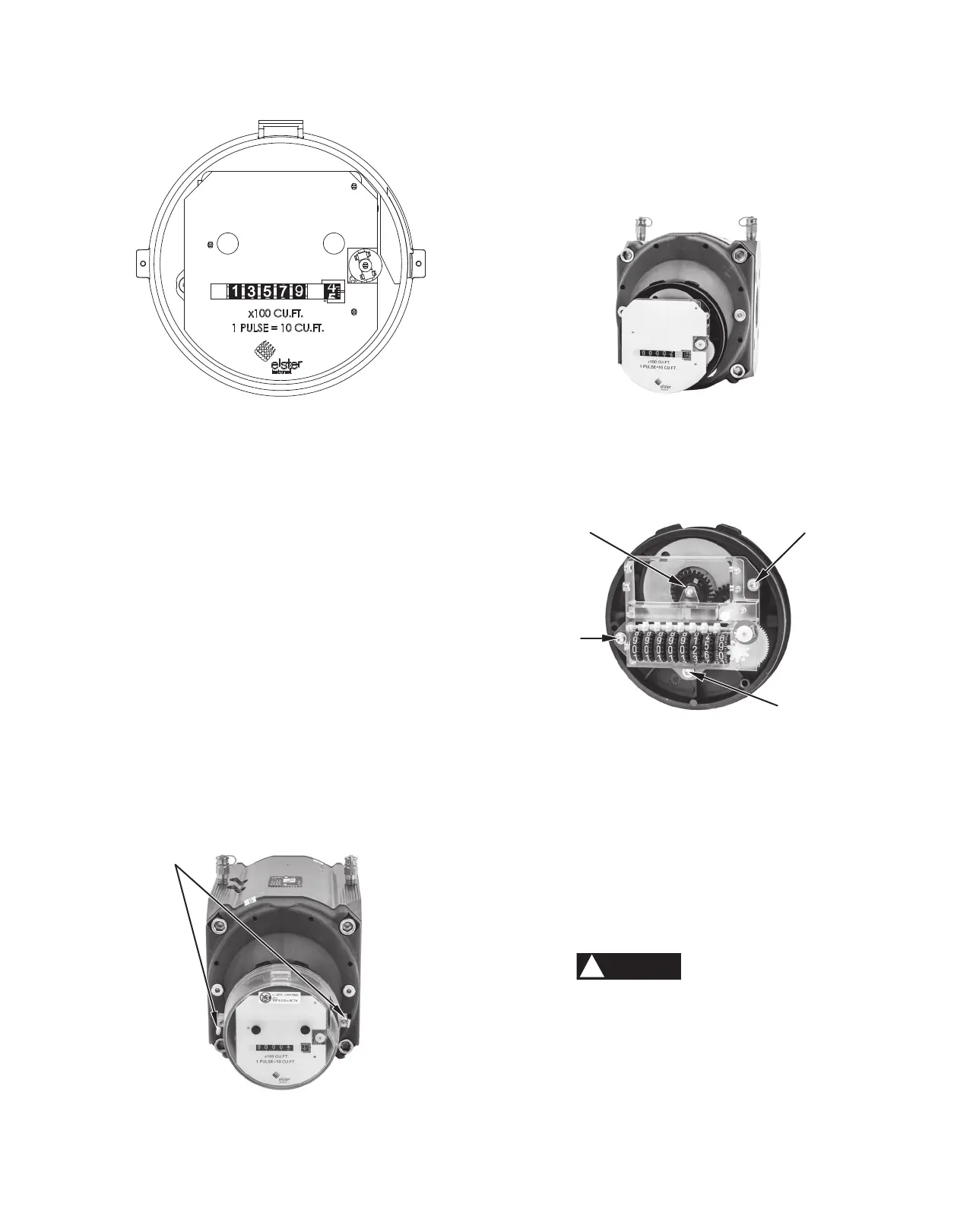

Figure 10. Index

Figure 11. Index cover seals

Figure 12. Index masking plate

c) How to “Clock” a Meter

The odometer index can be used to calculate the instantaneous

flow rate by using the right-most digit (test dial). Each number

on this dial represents one (1) cubic foot, and one complete

revolution of this dial represents ten (10) cubic feet. You will

need a stop watch or a watch with a sweep second hand to

calculate flow rate.

1. Measure the time, in seconds, that it takes the test dial to

make one complete revolution (10 cubic feet).

2. Use the following formula to calculate flow rate:

Flow Rate (acfh) = (10 ÷ “time”) x 3600

Note that the odometer index does not compensate for

elevated pressure or temperature. Correction factors will

need to be applied to adjust the ow rate to standard

conditions (scfh)

.

d) Removal, Installation and Replacement

Steps to replace the RABO meter index:

1. Cut the seal wires and remove from the holes [Figure 11].

2. Remove (unscrew) the two brass screws on the sides of

the index cover [Figure 11].

5. Remove the three index retaining screws using a Torx

T20 driver [Figure 13].

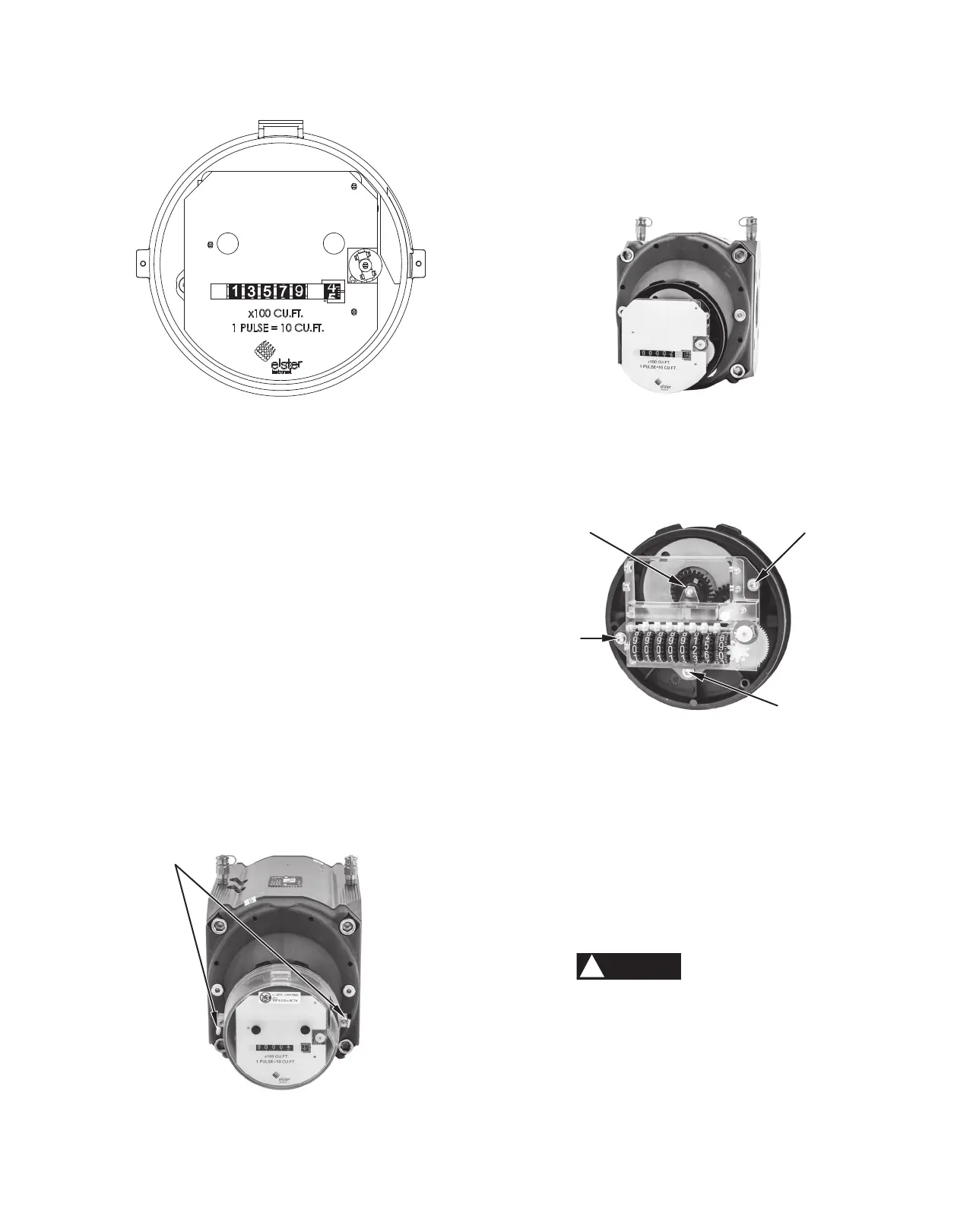

Figure 13. Index retaining screws

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

SEALS

6. Carefully remove the index.

• Pay attention to the driven magnet — it is supported

by the index.

• Leave the magnet on the meter.

7. Transfer the change gear from the damaged index to the

replacement [Figures 14 and 15].

• Remove the change gear on the damaged index.

• Pry the locking collar off with a knife blade or other

sharp object.

• Unscrew the change gear.

!

WARNING

Each meter size uses a common index that has

unique colored gears. Interchanging colored

gears will result in inaccurate readings. Ensure

the replacement index has the same color gears.

[Refer to Table 1]

• If the replacement index has a change gear, remove

and discard it.

• Attach the change gear from the damaged index to

the same shaft on the replacement index.

• Secure gear on shaft.

• Snap on the locking collar.

SUPPORT

HOLE

RABO

®

Rotary Gas Meter 09 Elster Instromet

3. Pull off the index cover.

• It helps to rock it slightly.

• Be careful not to damage the masking plate and

index when removing the cover.

4. Carefully pull off the index masking plate [Figure 12].

Figure 10. Index

Figure 11. Index cover seals

Figure 12. Index masking plate

c) How to “Clock” a Meter

The odometer index can be used to calculate the instantaneous

flow rate by using the right-most digit (test dial). Each number

on this dial represents one (1) cubic foot, and one complete

revolution of this dial represents ten (10) cubic feet. You will

need a stop watch or a watch with a sweep second hand to

calculate flow rate.

1. Measure the time, in seconds, that it takes the test dial to

make one complete revolution (10 cubic feet).

2. Use the following formula to calculate flow rate:

Flow Rate (acfh) = (10 ÷ “time”) x 3600

Note that the odometer index does not compensate for

elevated pressure or temperature. Correction factors will

need to be applied to adjust the ow rate to standard

conditions (scfh)

.

d) Removal, Installation and Replacement

Steps to replace the RABO meter index:

1. Cut the seal wires and remove from the holes [Figure 11].

2. Remove (unscrew) the two brass screws on the sides of

the index cover [Figure 11].

5. Remove the three index retaining screws using a Torx

T20 driver [Figure 13].

Figure 13. Index retaining screws

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

SEALS

6. Carefully remove the index.

• Pay attention to the driven magnet — it is supported

by the index.

• Leave the magnet on the meter.

7. Transfer the change gear from the damaged index to the

replacement [Figures 14 and 15].

• Remove the change gear on the damaged index.

• Pry the locking collar off with a knife blade or other

sharp object.

• Unscrew the change gear.

!

WARNING

Each meter size uses a common index that has

unique colored gears. Interchanging colored

gears will result in inaccurate readings. Ensure

the replacement index has the same color gears.

[Refer to Table 1]

• If the replacement index has a change gear, remove

and discard it.

• Attach the change gear from the damaged index to

the same shaft on the replacement index.

• Secure gear on shaft.

• Snap on the locking collar.

SUPPORT

HOLE

RABO

®

Rotary Gas Meter 09 Elster Instromet

3. Pull off the index cover.

• It helps to rock it slightly.

• Be careful not to damage the masking plate and

index when removing the cover.

4. Carefully pull off the index masking plate [Figure 12].

Figure 10. Index

Figure 11. Index cover seals

Figure 12. Index masking plate

c) How to “Clock” a Meter

The odometer index can be used to calculate the instantaneous

flow rate by using the right-most digit (test dial). Each number

on this dial represents one (1) cubic foot, and one complete

revolution of this dial represents ten (10) cubic feet. You will

need a stop watch or a watch with a sweep second hand to

calculate flow rate.

1. Measure the time, in seconds, that it takes the test dial to

make one complete revolution (10 cubic feet).

2. Use the following formula to calculate flow rate:

Flow Rate (acfh) = (10 ÷ “time”) x 3600

Note that the odometer index does not compensate for

elevated pressure or temperature. Correction factors will

need to be applied to adjust the ow rate to standard

conditions (scfh)

.

d) Removal, Installation and Replacement

Steps to replace the RABO meter index:

1. Cut the seal wires and remove from the holes [Figure 11].

2. Remove (unscrew) the two brass screws on the sides of

the index cover [Figure 11].

5. Remove the three index retaining screws using a Torx

T20 driver [Figure 13].

Figure 13. Index retaining screws

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

SEALS

6. Carefully remove the index.

• Pay attention to the driven magnet — it is supported

by the index.

• Leave the magnet on the meter.

7. Transfer the change gear from the damaged index to the

replacement [Figures 14 and 15].

• Remove the change gear on the damaged index.

• Pry the locking collar off with a knife blade or other

sharp object.

• Unscrew the change gear.

!

WARNING

Each meter size uses a common index that has

unique colored gears. Interchanging colored

gears will result in inaccurate readings. Ensure

the replacement index has the same color gears.

[Refer to Table 1]

• If the replacement index has a change gear, remove

and discard it.

• Attach the change gear from the damaged index to

the same shaft on the replacement index.

• Secure gear on shaft.

• Snap on the locking collar.

SUPPORT

HOLE

RABO

®

Rotary Gas Meter 09 Elster Instromet

3. Pull off the index cover.

• It helps to rock it slightly.

• Be careful not to damage the masking plate and

index when removing the cover.

4. Carefully pull off the index masking plate [Figure 12].

Figure 10. Index

Figure 11. Index cover seals

Figure 12. Index masking plate

c) How to “Clock” a Meter

The odometer index can be used to calculate the instantaneous

flow rate by using the right-most digit (test dial). Each number

on this dial represents one (1) cubic foot, and one complete

revolution of this dial represents ten (10) cubic feet. You will

need a stop watch or a watch with a sweep second hand to

calculate flow rate.

1. Measure the time, in seconds, that it takes the test dial to

make one complete revolution (10 cubic feet).

2. Use the following formula to calculate flow rate:

Flow Rate (acfh) = (10 ÷ “time”) x 3600

Note that the odometer index does not compensate for

elevated pressure or temperature. Correction factors will

need to be applied to adjust the ow rate to standard

conditions (scfh)

.

d) Removal, Installation and Replacement

Steps to replace the RABO meter index:

1. Cut the seal wires and remove from the holes [Figure 11].

2. Remove (unscrew) the two brass screws on the sides of

the index cover [Figure 11].

5. Remove the three index retaining screws using a Torx

T20 driver [Figure 13].

Figure 13. Index retaining screws

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

SEALS

6. Carefully remove the index.

• Pay attention to the driven magnet — it is supported

by the index.

• Leave the magnet on the meter.

7. Transfer the change gear from the damaged index to the

replacement [Figures 14 and 15].

• Remove the change gear on the damaged index.

• Pry the locking collar off with a knife blade or other

sharp object.

• Unscrew the change gear.

!

WARNING

Each meter size uses a common index that has

unique colored gears. Interchanging colored

gears will result in inaccurate readings. Ensure

the replacement index has the same color gears.

[Refer to Table 1]

• If the replacement index has a change gear, remove

and discard it.

• Attach the change gear from the damaged index to

the same shaft on the replacement index.

• Secure gear on shaft.

• Snap on the locking collar.

SUPPORT

HOLE

Figure 5. Horizontal installation

Figure 6. Vertical installation

Figure 7. Sight glass

Figure 4. Side view

b) Mounting

1) Always follow your company’s procedures, and

applicable local codes and ordinances.

2) Ensure gas valves are closed.

3) Ensure the upstream piping is clean and free of any

debris.

4) Remove protective caps from meter inlet and outlet prior

to installation.

5) Ensure the impellers turn freely.

6) Ensure the direction of flow using the arrow on the

nameplate.

7) Ensure the meter orientation is correct. Impeller shafts

must be horizontal [Figure 4].

8) Connect the inlet and outlet pipe flanges using

appropriate bolts and gaskets. Inlet and outlet pipe

flanges should be parallel and should not introduce any

bind on the meter body when tightened.

9) Level meter to within 1/16" per foot in all directions and

tighten flange bolts evenly (maximum 80ft-lbs).

c) Adding Oil

!

WARNING

Add oil only to the index end of the meter.

1) Ensure gas valves are closed and meter and piping are

depressurized.

!

WARNING

Failure to depressurize the meter prior to removing

meter and/or components could result in personal

injury and/or property damage.

2) Remove oil fill plug in the counter end case cover using a

5mm hex key [Figures 5 and 6].

3) Using the supplied syringe and oil, slowly add oil until

it is +/-1/16" of the center of the sight glass [Figure 7].

DO NOT OVERFILL. Only use Shell Morlina lubricating oil.

!

WARNING

DO NOT remove any sight glasses. No maintenance

can be performed through these openings.

4) Reinstall the oil fill plug.

OIL

FILL

OIL

LEVEL

SIGHT

GLASS

OIL

DRAIN

OIL

FILL

OIL

FILL

OIL

FILL

OIL

LEVEL

SIGHT

GLASS

OIL

DRAIN

RABO

®

Rotary Gas Meter 04 Elster Instromet

c) How to “Clock” a Meter

d) Removal, Installation and Replacement

Figure 10. Index

Figure 11. Index cover seals

Figure 12. Index masking plate

Figure 13. Index retaining screws

The odometer index can be used to calculate the instantaneous

flow rate by using the right-most digit (test dial). Each number

on this dial represents one (1) cubic foot, and one complete

revolution of this dial represents ten (10) cubic feet. You will

need a stop watch or a watch with a sweep second hand to

calculate flow rate.

1. Measure the time, in seconds, that it takes the test dial to

make one complete revolution (10 cubic feet).

2. Use the following formula to calculate flow rate:

Flow Rate (acfh) = (10 ÷ “time”) x 3600

Note that the odometer index does not compensate for

elevated pressure or temperature. Correction factors will

need to be applied to adjust the flow rate to standard

conditions (scfh).

Steps to replace the RABO meter index:

1. Cut the seal wires and remove from the holes [Figure 11].

2. Remove (unscrew) the two brass screws on the sides of

the index cover [Figure 11].

3. Pull off the index cover.

• It helps to rock it slightly.

• Be careful not to damage the masking plate and

index when removing the cover.

4. Carefully pull off the index masking plate [Figure 12].

5. Remove the three index retaining screws using a Torx

T20 driver [Figure 13].

6. Carefully remove the index.

• Pay attention to the driven magnet — it is supported

by the index.

• Leave the magnet on the meter.

7. Transfer the change gear from the damaged index to the

replacement [Figures 14 and 15].

• Remove the change gear on the damaged index.

• Pry the locking collar off with a knife blade or other

sharp object.

• Unscrew the change gear.

• If the replacement index has a change gear, remove

and discard it.

• Attach the change gear from the damaged index to

the same shaft on the replacement index.

• Secure gear on shaft.

• Snap on the locking collar.

Each meter size uses a common index that has

unique colored gears. Interchanging colored

gears will result in inaccurate readings. Ensure

the replacement index has the same color gears.

[Refer to Table 1]

Loading...

Loading...