ELSTER RABO

®

Rotary Gas Meter 11 Honeywell

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection:

II 2 G EEx ia 2C T4

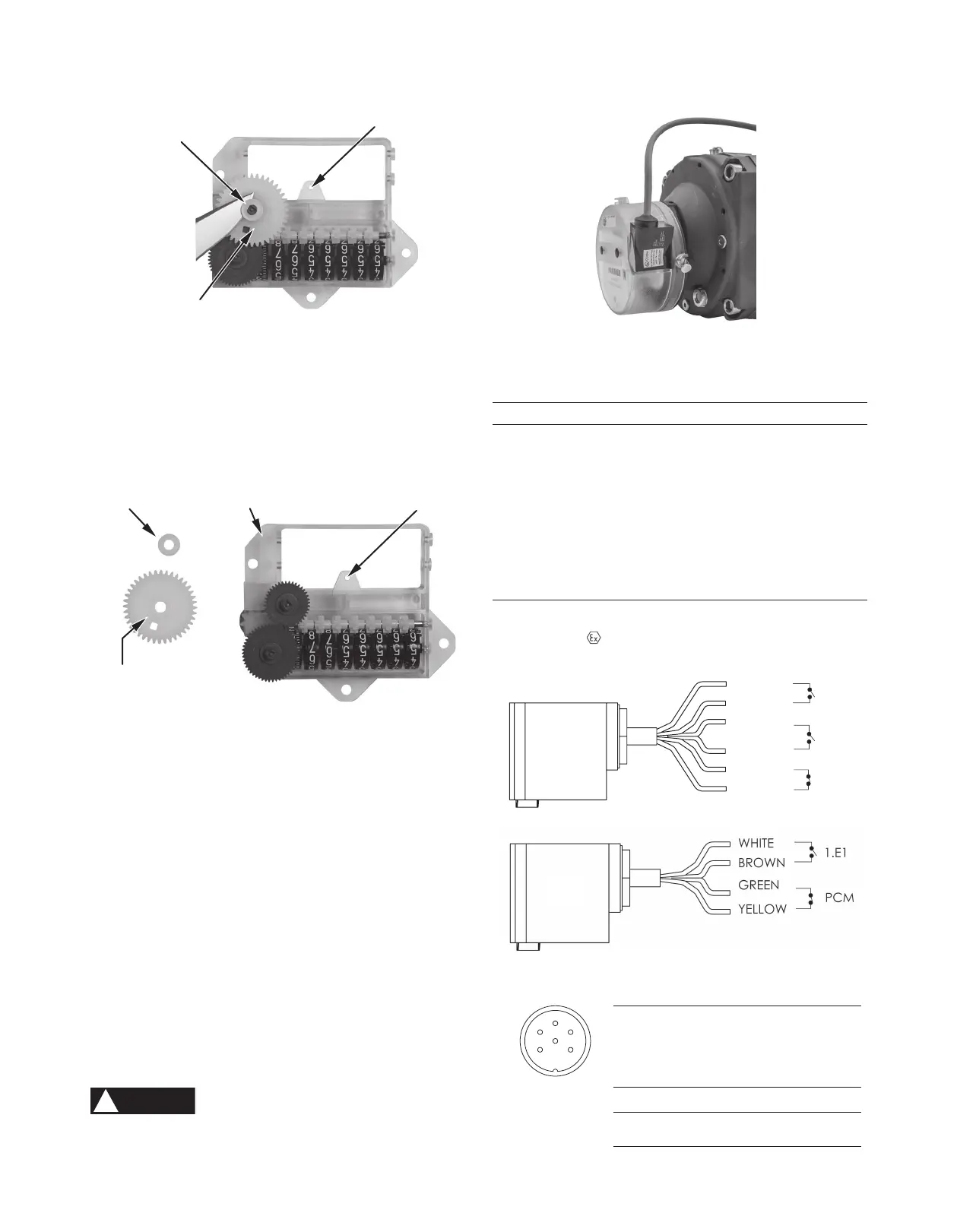

Figure 16. IN-S10 pulser installed

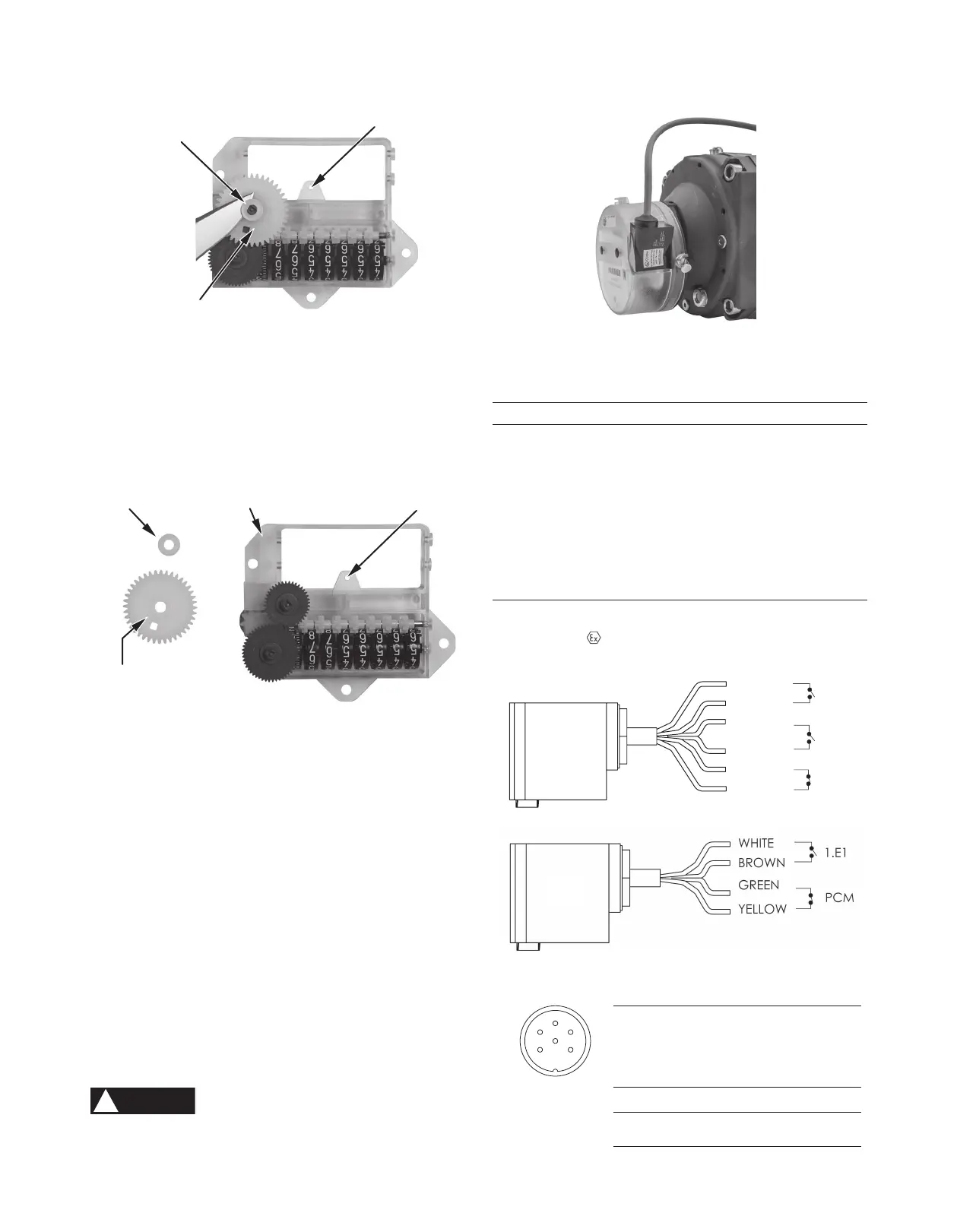

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250

Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection:

II 2 G EEx ia 2C T4

Figure 16. IN-S10 pulser installed

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250

Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection:

II 2 G EEx ia 2C T4

Figure 16. IN-S10 pulser installed

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250

Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection:

II 2 G EEx ia 2C T4

Figure 16. IN-S10 pulser installed

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250

Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

Figure 5. Horizontal installation

Figure 6. Vertical installation

Figure 7. Sight glass

Figure 4. Side view

b) Mounting

1) Always follow your company’s procedures, and

applicable local codes and ordinances.

2) Ensure gas valves are closed.

3) Ensure the upstream piping is clean and free of any

debris.

4) Remove protective caps from meter inlet and outlet prior

to installation.

5) Ensure the impellers turn freely.

6) Ensure the direction of flow using the arrow on the

nameplate.

7) Ensure the meter orientation is correct. Impeller shafts

must be horizontal [Figure 4].

8) Connect the inlet and outlet pipe flanges using

appropriate bolts and gaskets. Inlet and outlet pipe

flanges should be parallel and should not introduce any

bind on the meter body when tightened.

9) Level meter to within 1/16" per foot in all directions and

tighten flange bolts evenly (maximum 80ft-lbs).

c) Adding Oil

!

WARNING

Add oil only to the index end of the meter.

1) Ensure gas valves are closed and meter and piping are

depressurized.

!

WARNING

Failure to depressurize the meter prior to removing

meter and/or components could result in personal

injury and/or property damage.

2) Remove oil fill plug in the counter end case cover using a

5mm hex key [Figures 5 and 6].

3) Using the supplied syringe and oil, slowly add oil until

it is +/-1/16" of the center of the sight glass [Figure 7].

DO NOT OVERFILL. Only use Shell Morlina lubricating oil.

!

WARNING

DO NOT remove any sight glasses. No maintenance

can be performed through these openings.

4) Reinstall the oil fill plug.

OIL

FILL

OIL

LEVEL

SIGHT

GLASS

OIL

DRAIN

OIL

FILL

OIL

FILL

OIL

FILL

OIL

LEVEL

SIGHT

GLASS

OIL

DRAIN

RABO

®

Rotary Gas Meter 04 Elster Instromet

Figure 14. Change gear removal

Figure 15. Index, change gear and locking collar

Figure 16. IN-S10 pulser installed

Figure 17. Pulser connections

Table 1

Meter Gear Color

3.5M/G65

5.5M/G100

9M/G160

14M/G250

White

Dark Green

Green

Red

12. Pulser

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a

pulser is quick and easy, and requires no disassembly. To install

a pulser, simply slide the pulser into the slot on the index cover

[Figure 16], and connect the wires to the desired auxiliary devices

[Figure 17]. The pulser can be secured to the index cover screw with

a seal wire to mitigate and indicate tampering.

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection:

II 2 G EEx ia 2C T4

Figure 16. IN-S10 pulser installed

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250

Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

(Ui)

(Ii)

(Pi)

V

I

25

V

I

0,25

V

I

II 2 G Ex ia IIC T4 Gb

Pulser Pin-Out Connections

Connector

1.E1

Pulse

Out 1

2.E1

Pulse

Out 2

PCM

Tamper

Circuit

IN-S11 1 + 2 5 + 6 3 + 4

IN-S12

1 + 2

(Back)

1 + 2

(Front)

3 + 4

(Front)

WHITE

BROWN

GREEN

YELLOW

GREY

PINK

1.E1

2.E1

PCM

Figure 17. Pulser connections

Technical Specifications

Description Min. Typ. Max. Unit

Voltage (U) 24

V

Current (I) 76 mA

Power (P) 1.1

W

Static Contact Resistance 200 mΩ

Insulation Resistance 10

9

Ω

Breakdown Voltage 100 100 VDC

Switching Time Including Bounce 0.5 ms

Release Time 0.1 ms

Temperature range: -40°C … +70°C

IP-Class: IP67

Explosion protection: II 2 G EEx ia 2C T4

Figure 16. IN-S10 pulser installed

Figure 15. Index, change gear and locking collar

8. Install the replacement index.

• Orient the index so the mounting holes line up with

the posts in the base plate.

• Carefully ensure the shaft on the magnet holder is in

the support hole on the index frame [Figure 13].

• Install the three screws to retain the index to the base

plate. Tighten to snug.

9. Install index masking plate.

10. Install index cover.

11. Install security seals.

LOCKING COLLAR

CHANGE GEAR

INDEX

Meter Gear Color

3.5M/G65 White

5.5M/G100 Dark Green

9M/G160 Green

14M/G250 Red

Table 1

LOCKING COLLAR

CHANGE GEAR

SUPPORT HOLE

SUPPORT HOLE

Figure 14. Change gear removal

12. Pulser

All RABO meter indexes can be easily outfitted with a pulse output

device to interface with auxiliary equipment. Installation of a pulser

is quick and easy, and requires no disassembly. To install a pulser,

simply slide the pulser into the slot on the index cover [Figure 16],

and connect the wires to the desired auxiliary devices [Figure 17].

The pulser can be secured to the index cover screw with a seal wire

to mitigate and indicate tampering.

!

WARNING

Explosion Hazard

Auxiliary equipment and interconnecting wiring must be in

accordance with local and national codes for hazardous areas.

1

2

3

4

5 6

RABO

®

Rotary Gas Meter 10 Elster Instromet

Loading...

Loading...