1. General Information

This manual covers the installation, operation and maintenance

for the Elster Instromet RABO Rotary Meter. Refer to EAM-TB5900

for additional information.

2. Intended Use and Application

Elster RABO meters are suitable for measuring most types of

clean, dry, non-corrosive common gases. They are NOT intended

for use on biogas, sewage gas, oxygen, acetylene or liquids of

any kind. Product life and measurement accuracy can be affected

by contamination in the gas stream. Periodic servicing will prolong

the life and performance of the meter.

3. Operating Principle

The RABO meter utilizes positive displacement principle of

operation which makes volumetric measurements by displacing

finite volumes of gas. The positive displacement occurs within

a cavity formed between the meter’s internal housing and its

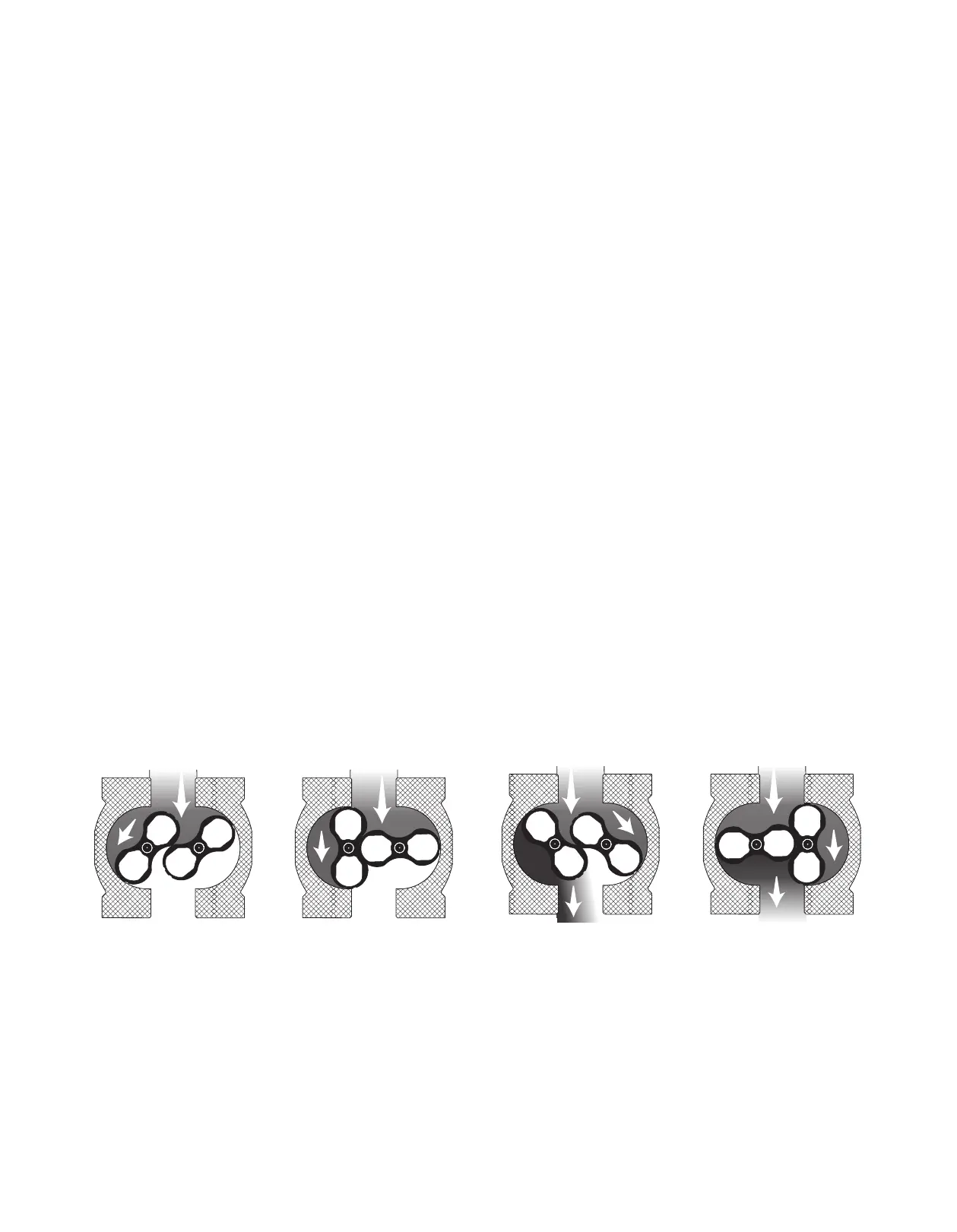

rotating impellers. The counter-rotating “figure-8” impellers [Figure

1] turn as a result of pressure drop across the meter’s inlet and

outlet created as downstream gas is consumed. The rotating

impellers separate the flowing gas into small, finite volumes

and are counted using a mechanical index. The RABO meter

has no wearing parts because precision clearances between

the impellers and meter body are maintained by timing gears,

which are designed to enhance long term accuracy. Combining

adequate filtration and periodic maintenance, a RABO meter will

remain accurate over many years.

As the left impeller rotates

toward the vertical position,

gas enters the cavity created

between the impeller

and the housing.

When the left impeller

reaches the vertical

position, a nite volume

of gas is captured in the

left cavity.

As the impellers continue

to turn, the volume of gas in

the left cavity is discharged.

Simultaneously, gas is

entering the space between

the right impeller and

housing.

After further rotation, the

right impeller becomes

vertical and a nite volume

of gas is captured in the

right cavity.

Figure 1. Operating Principle

Table of Contents

1. General Information 2

2. Intended Use and Application

2

3. Operating Principle

2

4. Receiving, Handling and Storage

3

5. Installation

3

6. Start-up/Commissioning

5

7. Decommissioning and Removal

5

8. Inspection and Maintenance

5

9. Testing

5

10. Technical Data

7

11. Index

8

12. Pulser 10

13. Thermowell 11

14. Auxiliary Equipment Mounting 11

15. Troubleshooting 11

RABO

®

Rotary Gas Meter

RABO

®

Rotary Gas Meter 02 Elster Instromet

RABO

®

Rotary Gas Meter

1. General Information 3

2. Intended Use and Application 3

3. Operating Principle 3

4. Receiving, Handling and Storage 4

5. Installation 4

6. Start-up/Commissioning 6

7. Decommissioning and Removal 6

8. Inspection and Maintenance 6

9. Testing 6

10. Technical Data 8

11. Index 9

12. Pulser 11

13. Thermowell 12

14. Instrument Drive (ID) 12

15. Auxiliary Equipment Mounting 14

16. Troubleshooting 15

Table of Contents

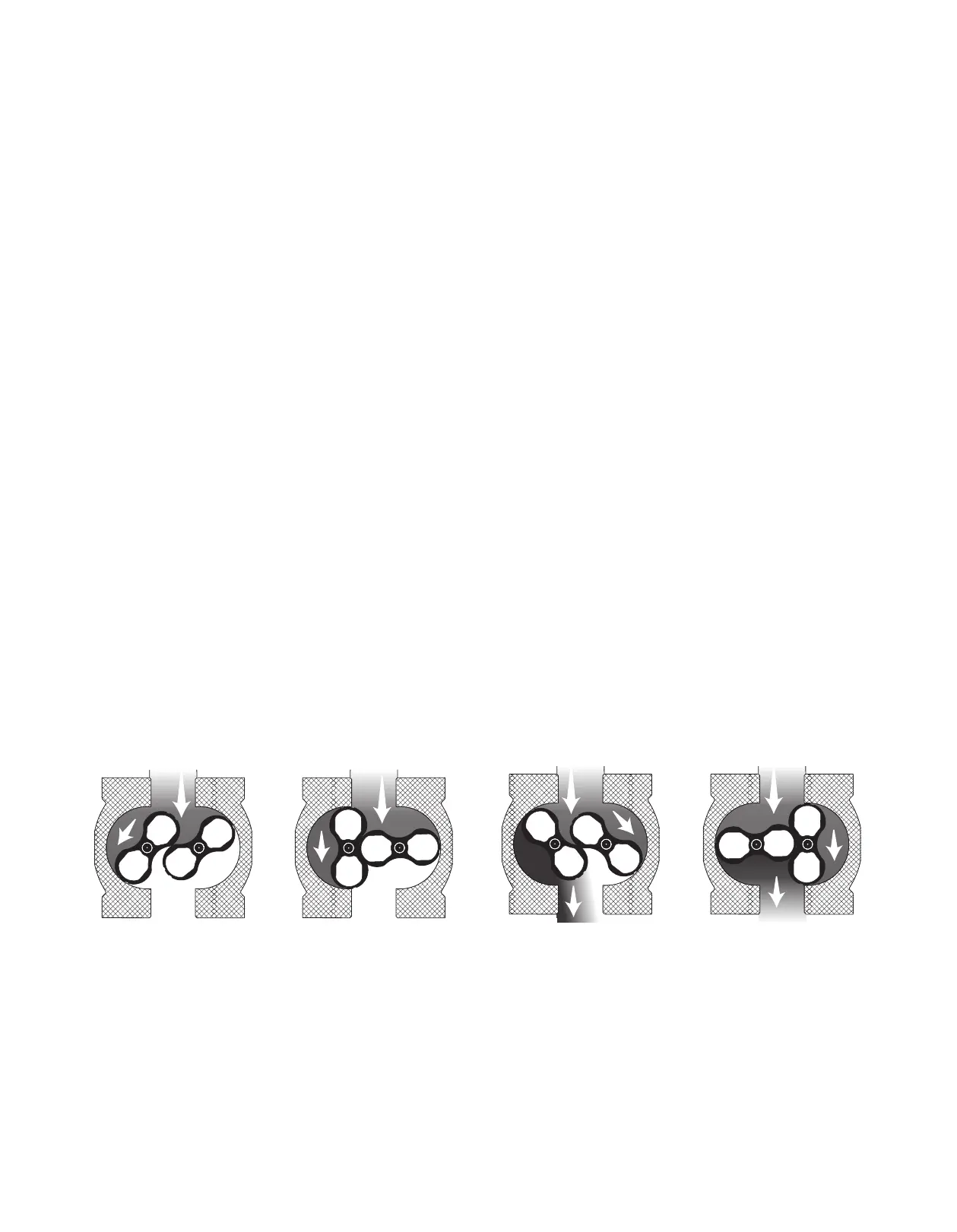

The RABO meter utilizes positive displacement principle of

operation which makes volumetric measurements by displacing

finite volumes of gas. The positive displacement occurs within

a cavity formed between the meter’s internal housing and its

rotating impellers. The counter-rotating “figure-8” impellers [Figu

re

1] turn as a result of pressure drop across the meter’s inlet and

outlet created as downstream gas is consumed. The rotating

impellers separate the flowing gas into small, finite volumes

and are counted using a mechanical index. The RABO meter

has no wearing parts because precision clearances between

the impellers and meter body are maintained by timing gears,

which are designed to enhance long term accuracy. Combining

adequate filtration and periodic maintenance, a RABO meter will

remain accurate over many years.

1. General Information

2. Intended Use and Application

3. Operating Principle

This manual covers the installation, operation and maintenance

for the Elster Instromet RABO Rotary Meter. Refer to EAM-TB5900

for additional information.

Elster RABO meters are suitable for measuring most types of

clean, dry, non-corrosive common gases. They are NOT intended

for use on biogas, sewage gas, oxygen, acetylene or liquids of

any kind. Product life and measurement accuracy can be affected

by contamination in the gas stream. Periodic servicing will prolong

the life and performance of the meter.

Figure 1. Operating Principle

As the left impeller rotates

toward the vertical position,

gas enters the cavity created

between the impeller

and the housing.

When the left impeller

reaches the vertical

position, a finite volume

of gas is captured in the

left cavity.

As the impellers continue

to turn, the volume of gas in

the left cavity is discharged.

Simultaneously, gas is

entering the space between

the right impeller and

housing.

After further rotation, the

right impeller becomes

vertical and a finite volume

of gas is captured in the

right cavity.

ELSTER RABO

®

Rotary Gas Meter 03 Honeywell

Loading...

Loading...