ELSTER RABO

®

Rotary Gas Meter 13 Honeywell

iv) Unscrew the lock nut from the magnet holder

(THREADS ARE LEFT HAND) [Figure 17].

v) Unscrew the change gear from the magnet holder

(THREADS ARE LEFT HAND) [Figure 22].

vi) Assemble the change gear to the ID magnet holder

(THREADS ARE LEFT HAND).

(1) For 3.5M meters

(a) Apply Loctite

®

770 primer to the threads and mating

surfaces of the change gear and the magnet holder

[Figure 23]. Allow to dry for 30 seconds.

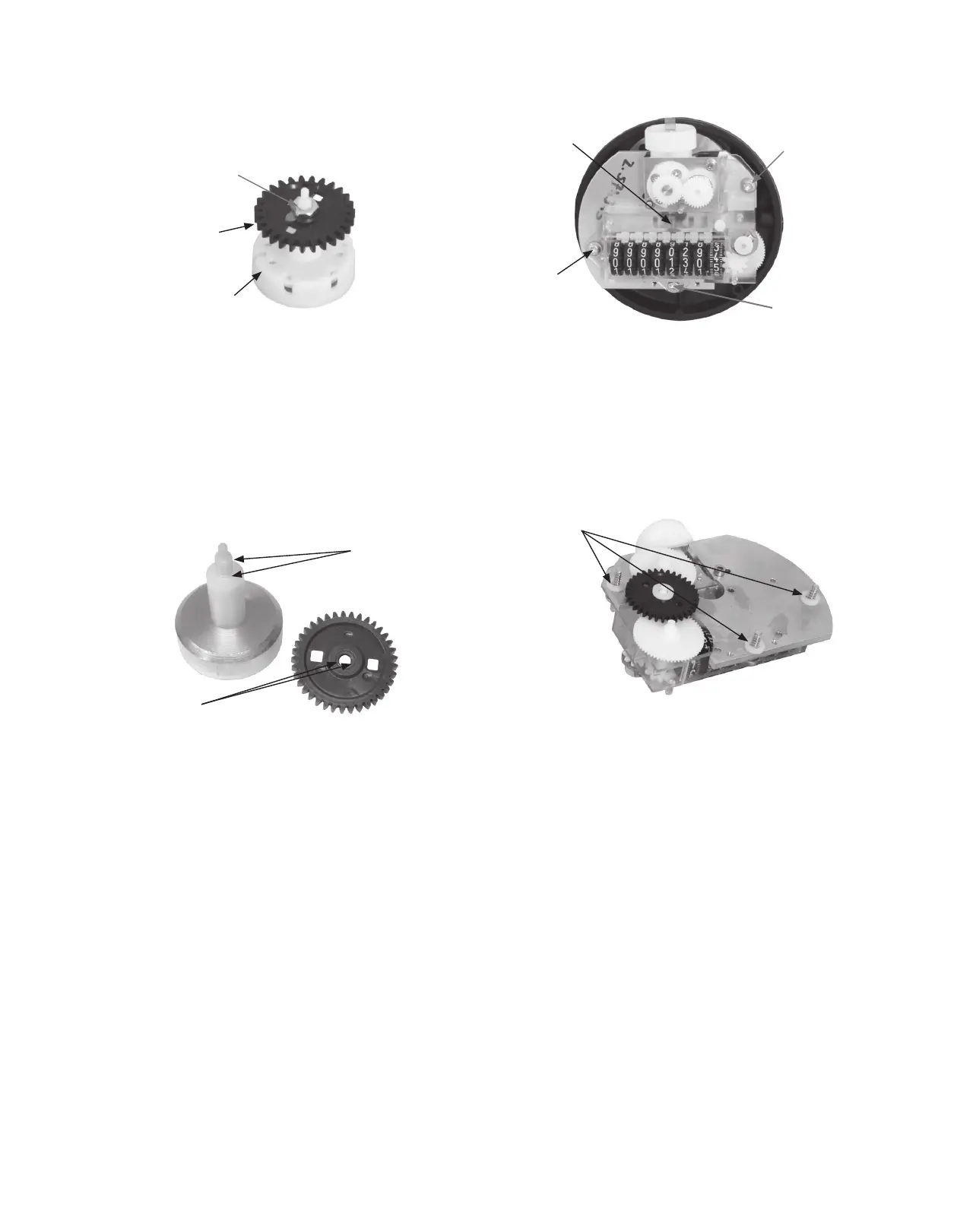

Figure 22. Magnet holder, change gear, and lock nut

CHANGE

GEAR

MAGNET

HOLDER

LOCK

NUT

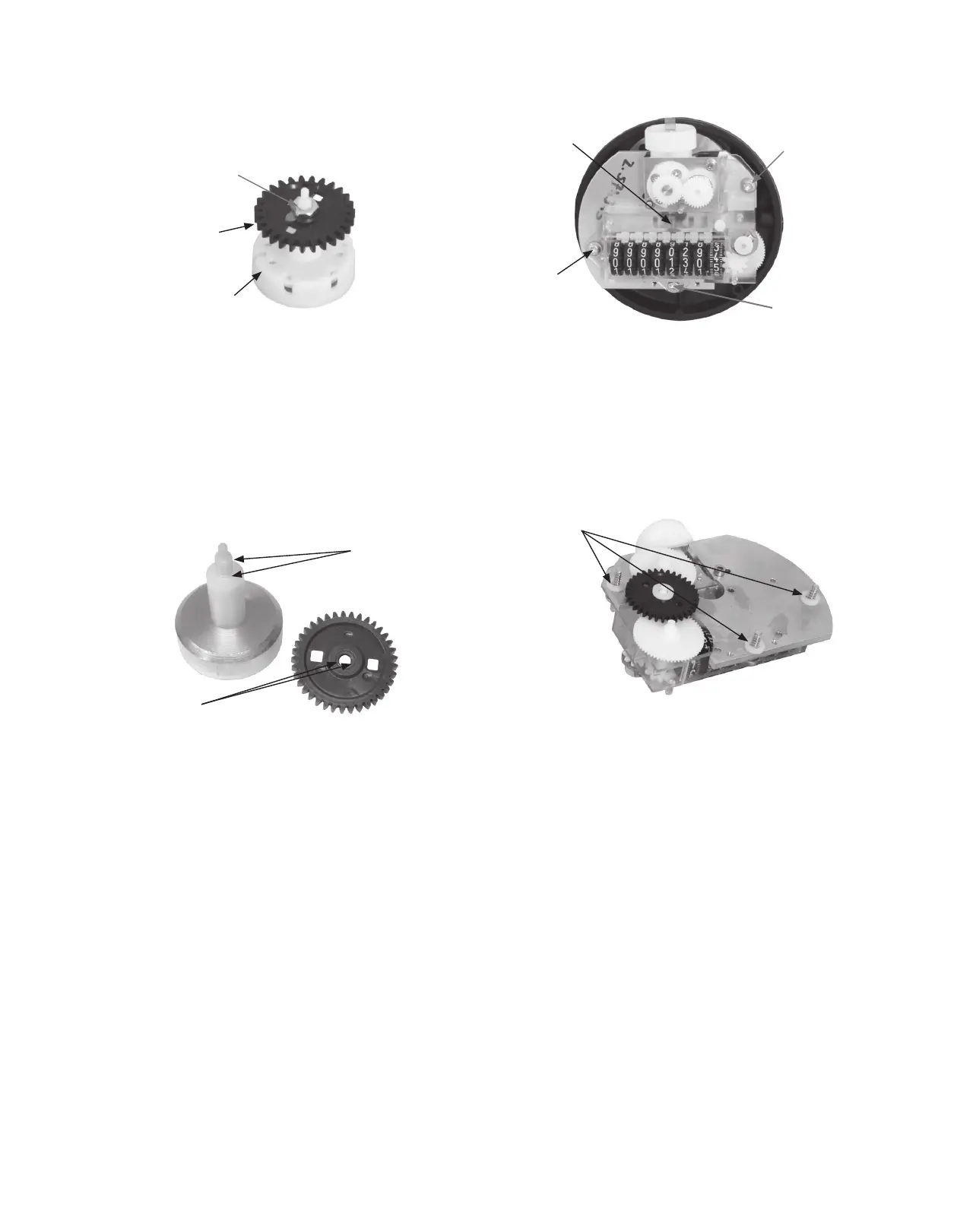

Figure 23. Magnet holder and change gear adhesive application

for 3.5M meter.

APPLY LOCTITE

®

PRIMER

APPLY LOCTITE

®

PRIMER. APPLY

CA

(b) Apply Loctite

®

406, Loctite

®

495, or equivalent

Cyanoacrylate adhesive to the threads and mating

surface of the magnet holder [Figure 23]. Do not get

the adhesive on the small tip of the magnet holder.

(c) Quickly screw the change gear to the magnet holder

(THREADS ARE LEFT HAND) and tighten until gear

is snugly seated against magnet holder. Let dry

completely

(d) Do not reinstall the locknut for a 3.5M meter.

(2) For 5.5M meters

(a) Screw the change gear to the magnet holder

(THREADS ARE LEFT HAND) and tighten until gear is

snugly seated against magnet holder.

(b) Reinstall the lock nut (THREADS ARE LEFT HAND)

removed in a previous step. Tighten until snug.

vii) Install the ID magnet holder onto the end of the meter.

viii) Install the ID gearing and index assembly on meter.

(1) Orient the ID gearing and index assembly so the

mounting screws line up with the posts in the index

base plate.

(2) Ensure the shaft on the magnet holder aligns with

the support hole on the index frame [Figure 24].

Figure 24.

ID retaining screws

INDEX

RETAINING

SCREW

SUPPORT

HOLE (ON

BACK SIDE)

INDEX

RETAINING

SCREW

INDEX

RETAINING

SCREW

(3) Tighten the three screws until snug. Do not overtighten.

(a) Each screw should have a 2mm thick retaining

washer to space the ID gearing and index assembly

away from the base plate [Figure 25]. The spacers

are installed at the factory. Verify they have not

fallen off.

Figure 25.

Retaining washers

RETAINING

WASHER

ix) Check for binds

(1) Using compressed air blown into the meter inlet port,

confirm the index and ID output shaft rotate freely.

x) Snap the ID index masking plate onto three posts

of the index.

xi) Install the ID index cover.

(1) Lightly lubricate the blue or purple o-ring on the index

base plate with silicone o-ring grease.

(a) Do not use petroleum based lubricants

on this o-ring.

(2) Place the ID index cover onto the index base plate while

aligning the holes on the side of the index cover with the

holes in the index base plate.

(3) Install the brass index cover mounting screws which

were removed in a previous step. Tighten the screws just

until the screw head contacts the cover, then back the

screw out until the seal wire holes align.

xii) Attach the support bracket to the accessory mount holes in

the meter case cover [Figure 19, 26].

(1) The ID can be attached to a meter installed for horizontal

or vertical flow. Use the appropriate accessory mount

holes.

NOTE: Regardless the meter orientation installation, the

ID adaptor plate must be mounted horizontally

during operation so that the ID mounted accessory is in

a vertical orientation.

Loading...

Loading...