RM7800E,G,L,M

OPERATION

31 65-0117—2

RUN/TEST SWITCH FUNCTIONS

The Run/Test Switch is located on the top side of the

RM7800, see Fig. 27. The Run/Test Switch allows the

burner sequence to be altered as follows:

1. In Prepurge Drive To High Fire Position, the Run/

Test Switch, when placed in the TEST position, will hold

in PREPURGE with the firing rate motor in the High Fire

position.

2. In the measured PREPURGE sequence, the Run/Test

Switch, when placed in the TEST position, will cause the

PREPURGE timing to stop. The firing rate motor will be in

the High Fire position.

3. In Prepurge Drive to Low Fire position, the Run/Test

Switch, when placed in the TEST position, will hold the

burner sequence in PREPURGE with the firing rate motor in

the Low Fire position.

4. In PFEP, the Run/Test Switch, when placed in the

TEST position, will stop the timer during the first eight

seconds when a ten second PFEP is selected or during the

first three seconds when a four second PFEP is selected,

allowing pilot-turn-down test and other burner adjustments

to be made. This activates a fifteen second flameout timer

that permits pilot flame adjustment without nuisance safety

shutdowns. The Run/Test Switch will be ignored during

PFEP for the RM7800E,L if terminals 8 and 9 or 9 and 21

are jumpered.

5. During RUN, the Run/Test Switch, when placed in

the TEST position, will drive the firing rate motor to the

Low Fire position.

NOTE: When RM7800 is switched to the TEST mode, it will

stop and hold at the next Run/Test Switch point in the

operating sequence. Make sure that the Run/Test Switch is

in the RUN position before leaving the installation.

WARNING

Do not use the Run/Test switch during the Pilot

Flame Establishing Period for the RM7800G,M

when using Direct Spark Function.

SELECTABLE SITE-CONFIGURABLE JUMPERS

The RM7800 has three site-configurable jumper options,

see Fig. 32 and Table 6. The site-configurable jumpers

should be clipped with side cutters and the resistors re-

moved from the Relay Module.

!

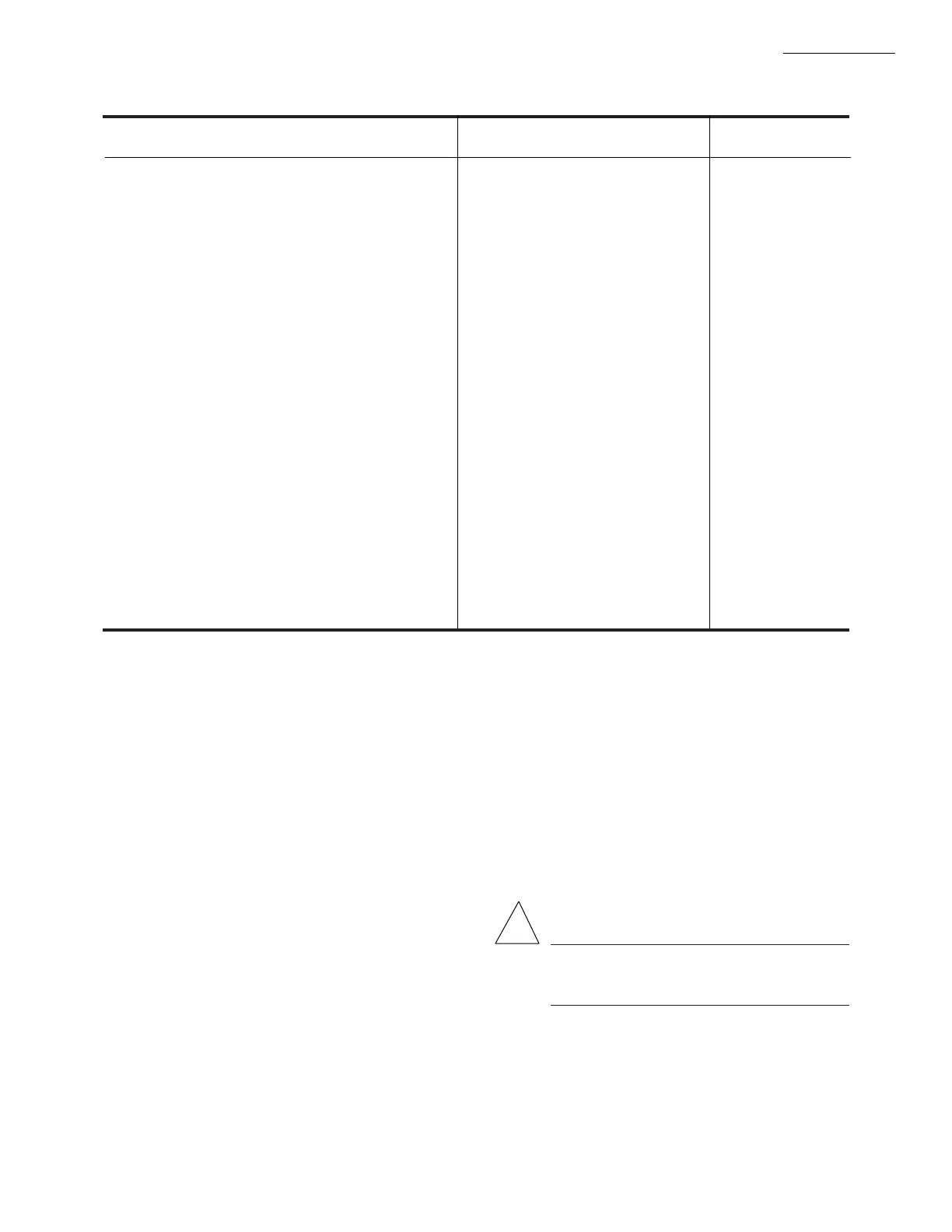

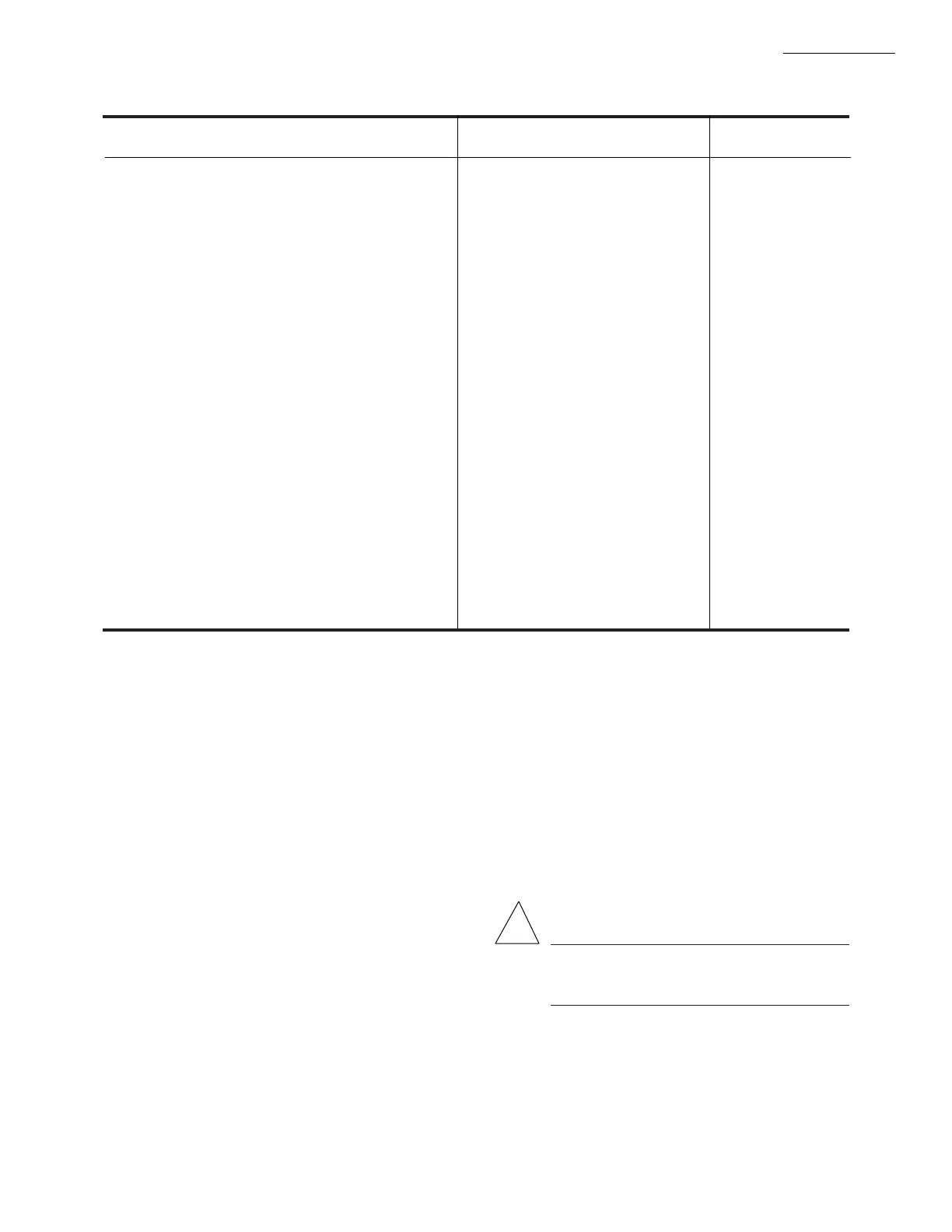

TABLE 5—EXPANDED ANNUNCIATOR MESSAGES.

Selectable Message Display Value First Line

(Second Line) (Second Line) Message

◊Expanded Annun.↔

◊Expanded Annunciator (EA not connected)<

◊Current Status (CS:)

a

EA Message< ↓EA

◊Valve Closure (Valve Close) T4 ON or OFF< ↓EA

◊Burner Switch (Burner Sw.) T5 ON or OFF< ↓EA

◊Operating Control (OperControl) T6 ON or OFF< ↓EA

◊Auxiliary Limit (Aux Limit 1) T7 ON or OFF< ↓EA

◊Auxiliary Limit (Aux Limit 2) T8 ON or OFF< ↓EA

◊Low Water Cutoff (LWCO) T9 ON or OFF< ↓EA

◊High Limit (High Limit) T10 ON or OFF< ↓EA

◊Auxiliary Limit (AuxLimit 3) T11 ON or OFF< ↓EA

◊Oil Selection Switch (Oil Select) T12 ON or OFF< ↓EA

◊High Oil Pressure Switch (Hi OilPres) T13 ON or OFF< ↓EA

◊Low Oil Pressure Switch (LowOilPres) T14 ON or OFF< ↓EA

◊High Oil Temperature Switch (Hi OilTemp) T15 ON or OFF< ↓EA

◊Low Oil Temperature Switch (LowOilTemp) T16 ON or OFF< ↓EA

◊Atomizing Switch (Atomize Sw) T19 ON or OFF< ↓EA

◊Gas Selection Switch (Gas Select) T17 ON or OFF< ↓EA

◊High Gas Pressure Switch (Hi GasPres) T18 ON or OFF< ↓EA

◊Low Gas Pressure Switch (LowGasPres) T19 ON or OFF< ↓EA

◊Airflow Switch (Airflow Sw) T20 ON or OFF< ↓EA

◊Auxiliary Interlock (Aux ILK 4) T21 ON or OFF< ↓EA

◊Auxiliary Interlock (Aux ILK 5) T22 ON or OFF< ↓EA

◊EA Fault Code nnn< ↓EA

◊Software Revision (SW Rev.) nnnn< ↓EA

a

Expanded Annunciator Diagnostic Current Status Messages can be reviewed in 7800 SERIES System Annunciation

Diagnostics and Troubleshooting, form 65-0118, Table 7.

Loading...

Loading...