S05, S10, S20 SERIES SPRING RETURN DIRECT COUPLED ACTUATORS

63-2607—08 4

Sizing

Required Torque

In lieu of data from a Specification Engineer or Manufacturer,

required torque for a given damper load can be determined

using the following method:

Where:

—T

R

= Required torque for the damper load.

—T

D

= Damper torque rating from the manufacturer,

expressed in either (lb-in.)/(sq ft) or (N•m)/(sq m). the

damper load.

—A

D

= Damper area expressed in either sq ft or sq m.

Actuators Required

In lieu of data from a Specification Engineer or Manufacturer,

the number of required actuators for a given damper load can

be determined using the following method:

Where:

— N = Number of actuators.

—T

R

= Required torque for the damper load. (See above.)

—T

A

= Actuator torque rating.

— SF = Safety factor.

NOTE: The safety factor accounts for variables such as mis-

alignments, aging of the damper, etc. 0.8 is a typical

safety factor.

INSTALLATION

When Installing this Product...

1. Read these instructions carefully. Failure to follow

them could damage the product or cause a hazardous

condition.

2. Check the ratings given in the instructions and on the

product to make sure the product is suitable for your

application.

3. Installer must be a trained, experienced service

technician.

4. After installation is complete, check out product

operation as provided in these instructions.

CAUTION

Electrical Shock or Equipment Damage Hazard.

Low voltage can shock individuals or short

equipment circuitry.

Disconnect power supply before installation.

IMPORTANT

All wiring must agree with applicable codes,

ordinances and regulations.

Location

These actuators are designed to mount directly to a damper

external drive shaft. The shaft coupling fastens to the drive

shaft. The actuator housing includes slots which, along with an

anti-rotation bracket, secure the actuator to the damper frame

or duct work (see Fig. 8).

NOTES:

— When mounted correctly, these slots allow the

actuator to float without rotating relative to the

damper shaft.

— Using other brackets or linkages, the actuator can

be foot-mounted or tandem-mounted.

CAUTION

Motor Damage Hazard.

Deteriorating vapors and acid fumes can damage

metal parts.

Install motor in areas free of acid fumes and other

deteriorating vapors.

CAUTION

Equipment Damage Hazard.

Tightly securing actuator to damper housing can

damage actuator.

Mount actuator to allow it to float along its vertical axis.

Preparation

Before mounting the actuator onto the damper shaft, determine

the:

— Damper/valve opening direction for correct spring return

rotation. The actuator can be mounted to provide clockwise

or counterclockwise spring return.

— Damper shaft size (see the Specifications section).

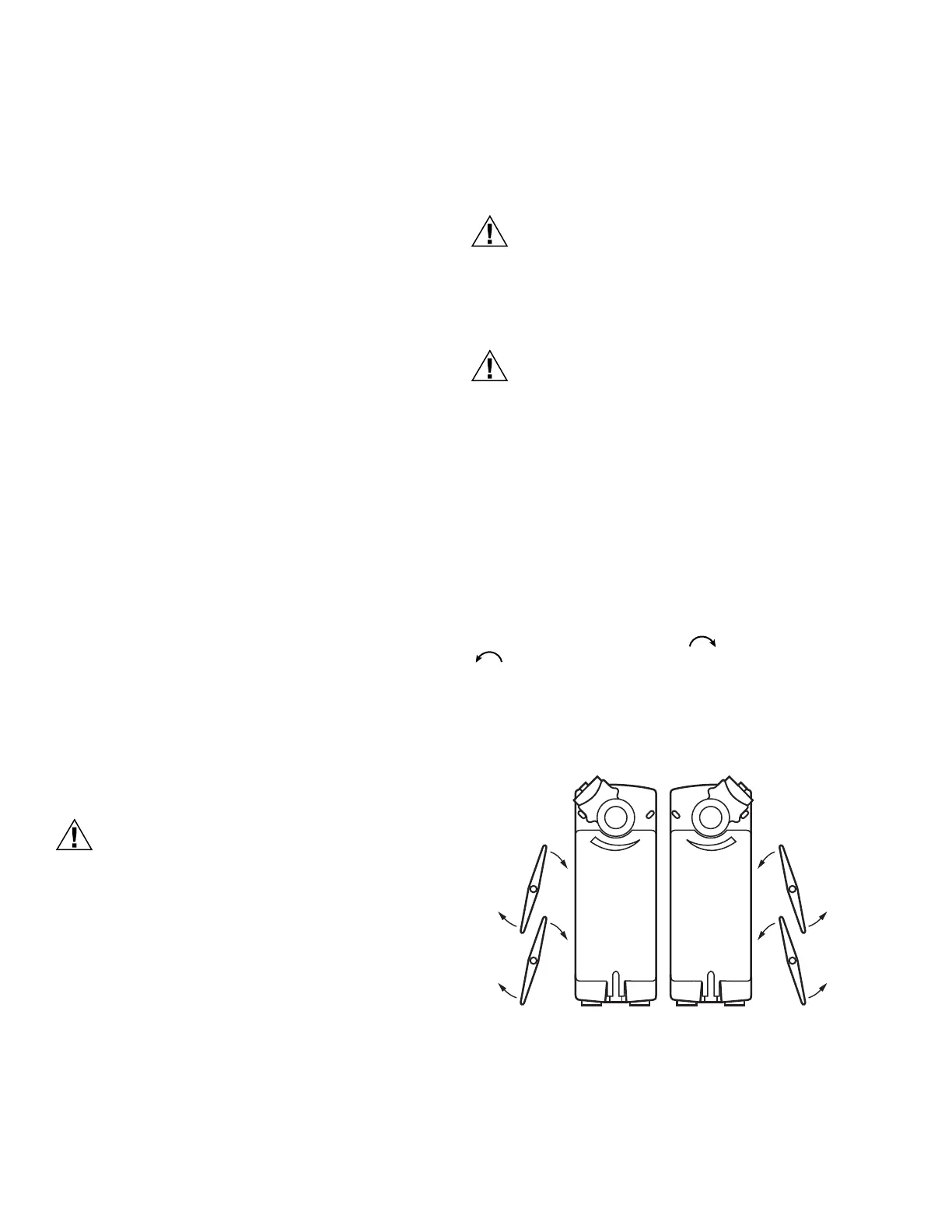

Determine Appropriate Mounting Orientation

The actuators are designed to open a damper by driving the

damper shaft in either a clockwise or counterclockwise

direction (see Fig. 2).

NOTES:

— Actuators are shipped in the fully closed (spring

return) position.

— An arrow molded into the hub points to tick marks

on the label to indicate the hub rotary position.

Fig. 2. Spring Return DCA mounting orientation.

Measure Damper/Valve Shaft Length

If the shaft is less than three inches in length, the shaft

coupling must be located between the damper/valve and

actuator housing. If the shaft length is more than three inches,

the shaft coupling may be located on either side of the actuator

housing.

T

R

T

D

A

D

×=

N

T

R

T

A

SF×

-------------------

=

M20953

CCW TO CLOSE

(FAIL-SAFE

POSITION)

CW TO OPEN

CW TO CLOSE

(FAIL-SAFE

POSITION)

CCW TO OPEN

Loading...

Loading...