S8600B,C,H,M; S8610B,C,H,M; S8670D,E,J,K INTERMITTENT PILOT GAS IGNITION CONTROL

บริษัท เอดีดี เฟอร์เนส จํากัด

ADD FURNACE CO.,LTD.

44 ซอยบรมราชชนนี 70 ถนนบรมราชชนนี แขวงศาลาธรรมสพน์ เขตทวีวัฒนา กรุงเทพฯ 10170

โทร: 02-888-3472 โทร: ออกแบบ:08-08-170-170 แฟกซ์: 02-888-3258

https://www.add-furnace.com E-mail: sales@add-furnace.com

—

Operating ambient temperatures between -40°F and 175°F (-

40°C and 79°C); (165°F [74°C] for S8610 and

S8670 models).

—

Relative humidity below 95% noncondensing.

—

Protection from water, steam or corrosive chemicals that are

used to clean the appliance.

—

Protection from dripping water, such as from an

overfilled humidifier or from condensation.

—

Protection from dust or grease accumulation.

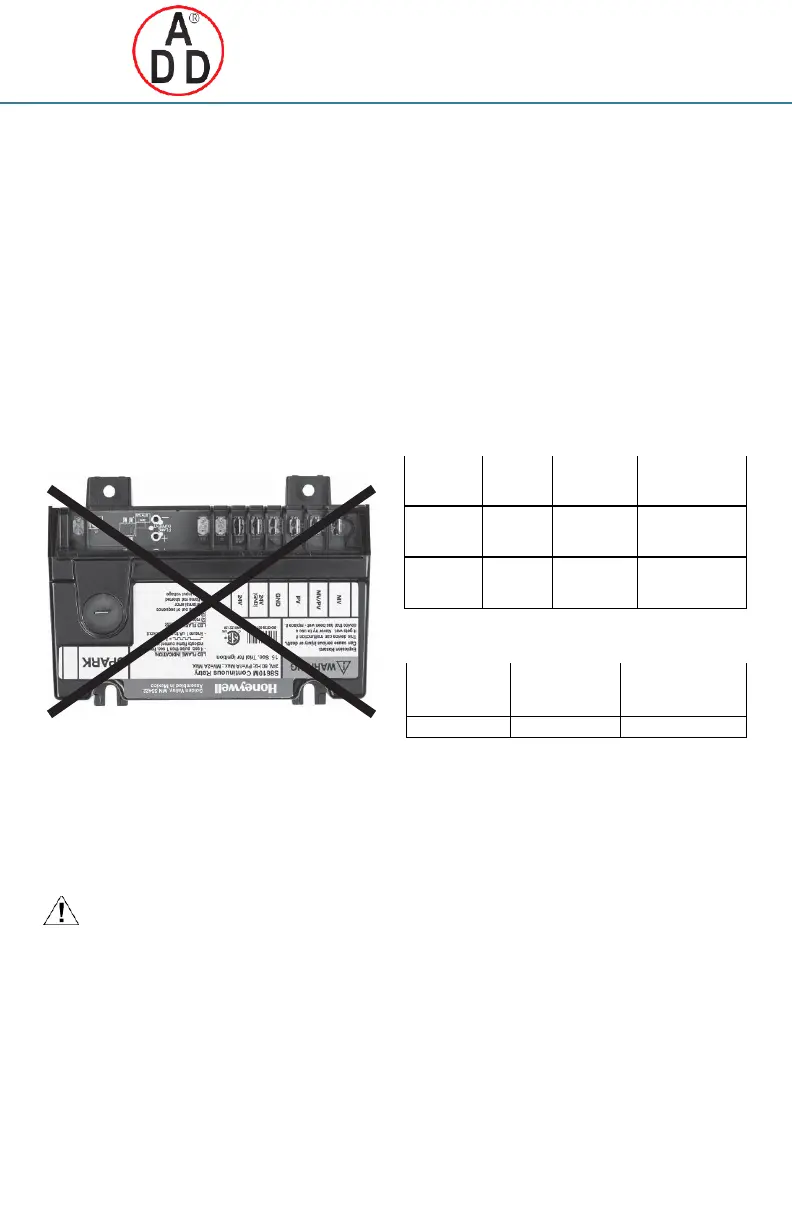

Mount the Ignition Module

Select a location close enough to the burner to allow a short (3 ft.

[0.9 m] max.), direct cable route to the pilot burner. Ambient

temperature at the module must be within the range listed under

Operating Temperature, on page 2. The module must be protected

from water, moisture, corrosive chemicals and excessive dust and

grease.

Mount the module with the terminals down to protect them from

dripping water and dust. As an alternative, it can also be mounted

with the terminals on either side.

IMPORTANT

Do not mount with terminals facing up.

M29897

Fig. 1. Incorrect Mounting (Model S8600M shown).

Fasten securely with four No. 6-32 machine or No. 8 sheet metal

screws.

Mount the System Controls

Mount any required controls, such as the gas control, spark

igniter, flame sensor, thermostat, limit, and transformer according

to manufacturer’s instructions.

Wire the System

CAUTION

Equipment Damage Hazard.

Disconnect power supply before beginning wiring or

making wiring connections to prevent electrical shock or

equipment damage.

All wiring must comply with local codes and ordinances. See Fig. 2

and Table 4 for proper wiring connections.

IMPORTANT

1.

As shown in the wiring diagrams, a common ground

is required on:

aThe pilot burner mounting bracket, and bThe

GND(BURNER) terminal on the ignition

module. Failure to use the GND(BURNER) terminal

may result in intermittent loss of spark and/or loss of

flame current sensitivity.

2.

Make sure the transformer has adequate VA. The

ignition module requires at least 0.1 A at 24 Vac. Add the

current draws of all other devices in the control circuit,

including the pilot and main valves in the gas control,

and multiply by 24 to determine the total VA requirement

of these components. Add this total to 2.4 VA (for the igni-

tion module). The result is the minimum trans- former VA

rating. Use a Class II transformer if replacement is

required.

CONNECT IGNITION CABLE

Use Honeywell ignition cable or construct an ignition cable that

conforms to suitable national standards such as Underwriters

Laboratories Inc. See Table 2 and Table 3.

.

Table 2. Honeywell Pre-assembled Ignition Cables (UL

Style 3257).

1/4 inch quick

connect,

insulated

Rajah connector

receptacle, 90 degree

rubber boot

1/4 inch quick

connect,

insulated

Rajah connector

receptacle, straight

rubber boot

Table 3. Recommended Ignition Cable for Field

Assembly.

Cable must be no longer than 36 in. (0.9 m). Solid conductor cable

recommended. To construct a cable, fit one end of ignition cable with

1/4 in. diameter Rajah connector receptacle and the other with a 1/4

in. female quick connect. Protect both ends with insulated boots.

NOTE: The cable must not run in continuous contact with a metal

surface or spark voltage will be greatly reduced. Use

ceramic or plastic standoff insulators as required.

Resistive spark cable reduces spark voltage and may

impact appliance performance.

To install:

(1)

Connect one end of the cable to the male quick

connect SPARK terminal on the igni- tion module.

(2)

Connect the other end of the cable to the igniter

or igniter-sensor stud on the pilot burner/igniter-

sensor.

CONNECT IGNITION MODULE

NOTE: Refer to Fig. 2 and Table 4 for the location of each

connection.

Loading...

Loading...