34-SM-03-01

Page 2

SMV 3000 Sensor and Flow Transmitter Functions

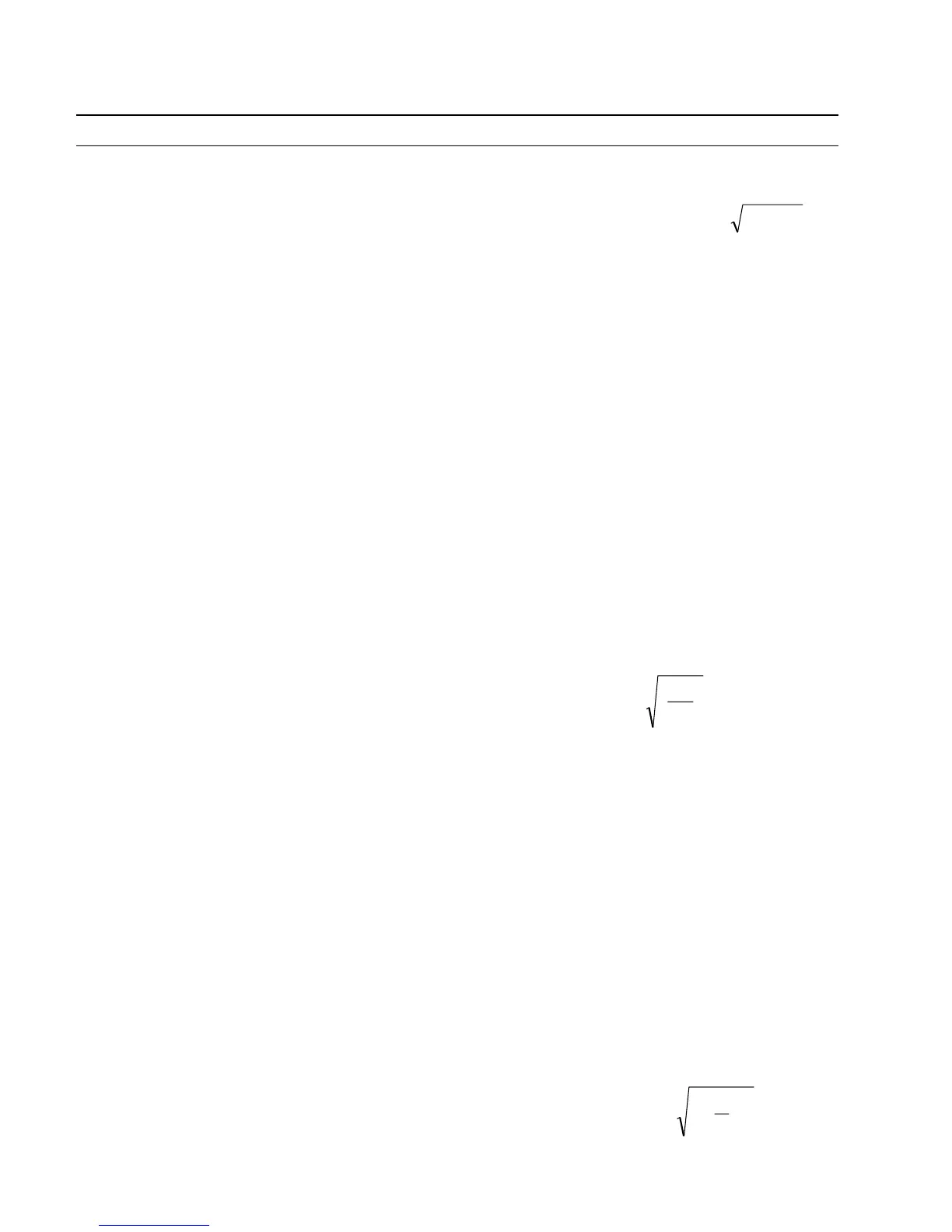

Honeywell’s SMV 3000 Smart

Multivariable Flow Transmitter

extends our proven “smart”

technology to the measurement

of three separate process

variables simultaneously with the

ability to calculate compensated

mass or volume flow rate as a

fourth process variable according

to industry standard methods for

air, gases, steam and liquids. It

measures differential pressure

and absolute or gauge pressure

from a single sensor and

temperature from a standard 100-

ohm Resistance Temperature

Detector (RTD) or thermocouple

type E, J, K, or T input signals.

The SMV 3000’s flow calculation

may include compensation of

pressure and/or temperature as

well as more complex variables

such as viscosity, discharge

coefficient, thermal expansion

factor, velocity of approach factor

and gas expansion factor.

Proven Pressure Sensor

Technology with

characterization

The SMV 3000 utilizes proven

Piezoresistive sensor technology

and has an ion-implanted silicon

chip hermetically sealed in its

meter body. This single

piezoresistive capsule actually

contains three sensors in one; a

differential pressure sensor, an

absolute or gauge pressure

sensor, and a meter body

temperature sensor. Process

pressure applied to the

transmitter’s diaphragm transfers

through the fill fluid to the sensor.

Voltage bridge circuits on the chip

measures the differential and

static pressures while a resistor in

a voltage divider measures the

temperature. These three input

signals from the sensor coupled

with the characterization data

stored in the transmitter EPROM

are then used by the

microprocessor to calculate

highly accurate pressure and

temperature compensated values

for the differential pressure and

static pressure measurements.

In this way, the SMV 3000 can

provide an output signal that is

stable and fully compensated for

changes in process pressure and

ambient temperature over a very

wide range. Microprocessor-

based electronics coupled with

the sensor characterization

provide higher span-turndown

ratio, improved temperature and

pressure compensation, and

improved accuracy.

Process Temperature

Measurement and

Compensation

Similar to the differential and

static pressure measurements,

the SMV 3000’s temperature

electronics are characterized for

ambient temperature changes so

that the resistance or millivolt

input from a Pt. 100 Ohm RTD or

Type J, K, T or E Thermocouple

is compensated for ambient

temperature effects and therefore

can be reported as the most

accurate temperature possible.

The SMV 3000’s flexibility allows

the connection of either a

standard 2, 3 or 4 wire 100 ohm

RTD or a Type J, K, T or E

thermocouple without special

installation consideration. RTDs,

thermocouples and thermowells

can be ordered from Honeywell

under this specification. See

pages 18 and 19.

Mass Flow Measurements for

Steam, Air, Gas or Liquid

The SMV 3000 includes flow

equations for steam, air, gas and

liquids so that one model is all

you need in your plant. The

mass flow equation with dynamic

compensation (Equation 1) is

based on the ASME MFC-3M-

1989 standard for orifice meters.

Equation 1:

Q

m

= NCE

v

Y

1

d

2

h

w

ρ

f

Where,

Q

m

= mass flowrate

N = units conversion factor

C = discharge coefficient

Y

1

- gas expansion factor

E

v

= velocity of approach factor

ρ

f

= density at flowing conditions

h

w

= differential pressure

d = bore diameter

SMV 3000 Flow Compensation

Most differential pressure

transmitters utilized in steam, gas

and liquid flow applications today

measure the differential pressure

across a primary flow element

and report it to a DCS, PLC or

flow computer for flow calculation.

Most often, the calculation inside

assumes that the density of the

fluid is constant per the following

equation.

Q

v

= K

h

w

ρ

Where,

Q

v

= volumetric flowrate

h

w

= differential pressure

K = flow factor

ρ = flowing density

In other applications, one will take

the equation a step further and

compensate for changes in

pressure and temperature using

additional pressure and

temperature transmitters. For

example, if a gas is being

measured, the following volumetric

flow equation based on multiple

transmitters - the “Old” approach -

applies (Figure 2). Or, in the case

of Mass flowrate,

Q

m

= K

h

P

T

w

Loading...

Loading...