34-SM-03-01

Page 3

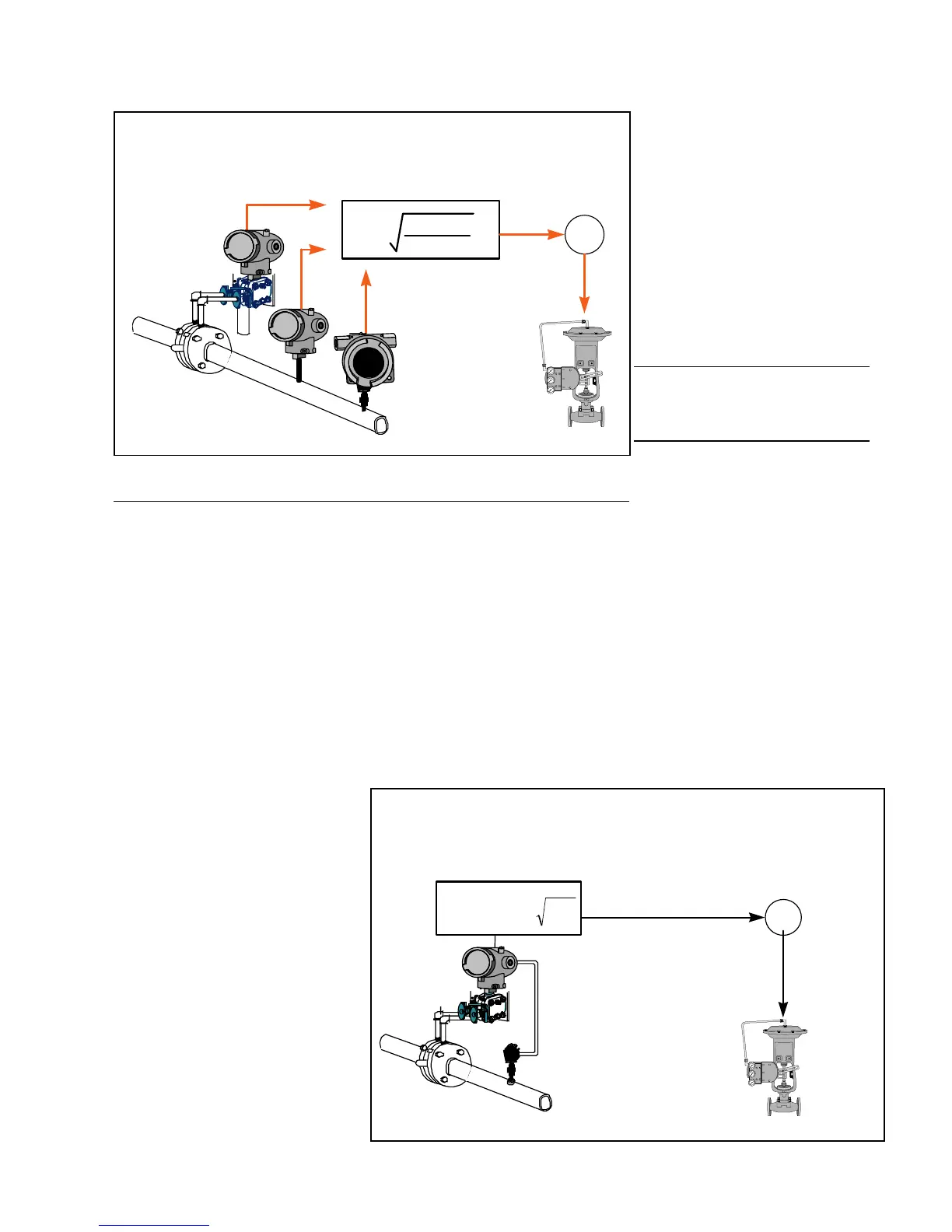

PT

Q

v

= k h

w

x T

P

FIC

Tem

.

DP

Pressure

PT

The “Old” Flow A

roach

Flow Com

uter or DCS

On the other hand, if you have a

more demanding flow application

utilizing an orifice plate or laminar

flow element that requires high

accuracy at larger flow

turndowns, choose the more

complex mass or volumetric flow

equation and compensate for

density as well as other variables

such as viscosity, discharge

coefficient, gas expansion factor,

velocity of approach factor and

thermal expansion factor.

Description of Flow

Variables for Dynamic Flow

Compensation

Figure 2 —Flow Compensation Using the “Old” Approach

Discharge Coefficient

Discharge coefficient is defined as

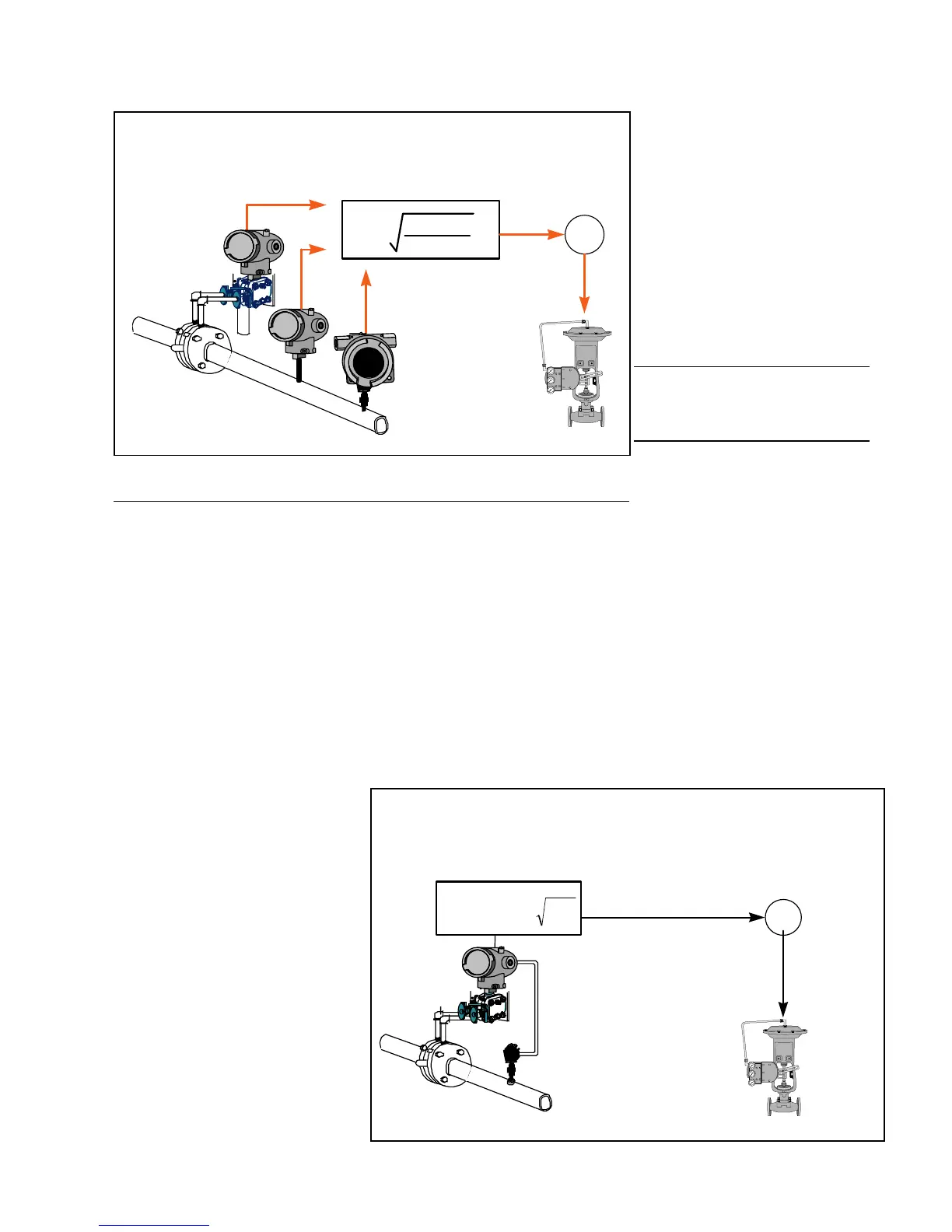

Today, the three key

measurements (differential

pressure, static pressure and

process temperature) and the flow

calculation can be made with one

multivariable transmitter. So,

whether you just want to

compensate for density or use full

dynamic flow compensation,

consider the SMV 3000 and the

“Enhanced” flow approach (Figure

3). Unlike most DP transmitters,

the SMV 3000 with dynamic

compensation can correct flow

With the SMV 3000, you have the

flexibility to choose which variables

you need to compensate. For

example, the

transmitter can be

easily configured to compensate

for density only and calculate

flowrate via a standard equation. If

you have a liquid, steam or gas

application with small flow

turndown requirements, choose the

easy, standard equation and in

minutes your mass or volumetric

flowrate is compensated for density

changes.

the true flowrate divided by the

theoretical flowrate and corrects

the theoretical equation for the

influence of velocity profile

(Reynolds number), the

assumption of no energy loss

between taps, and pressure tap

location. It is dependent on the

primary flow element, the β ratio

and the Reynolds number.

Reynolds number is in turn

dependent on the viscosity,

density and velocity of the fluid as

well as the pipe diameter per the

following

errors due to the K factor. Per

Equation 1, the K factor is not a

constant and can vary:

k = NCE

v

Y

1

d

2

Dynamic flow compensation is the

process of measuring the required

variables (differential pressure,

static pressure and temperature)

and using these variables to

perform real time, calculations of

variables such as density,

viscosity, Reynolds number,

discharge coefficient, thermal

expansion factor and gas

expansion factor - all which can

effect the accuracy of your mass

flow measurement.

SMV 3000

Transmitter

FIC

Control done in DCS

PLC

or Sin

le Loo

Controller

Tem

.

m

v

dh

w

1

2

PT

The “Enhanced” Flow A

roach

D

namic com

ensation of

Flow inside SMV 3000

Figure 3 —Flow Compensation Using the “Enhanced” Approach

Loading...

Loading...