Do you have a question about the Honeywell SmartLine ST700 and is the answer not in the manual?

General guidance on attaching the transmitter to pipes or brackets.

Details on using optional or existing mounting brackets.

Instructions for mounting the transmitter using a flange connection.

How to adjust the transmitter housing orientation for optimal viewing.

Critical step for small spans to ensure correct mounting orientation.

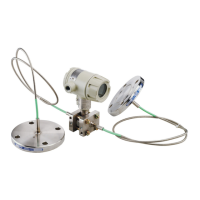

Procedures for flush and remote seal mounting configurations.

Procedures for installing conduit entry plugs and adapters for safe connection.

Steps for connecting power and loop wiring to the transmitter.

Safety requirements for explosion-proof installations in hazardous areas.

Configuring failsafe direction and write protect jumpers.

Procedure to zero the transmitter after mounting for accurate readings.

Overview of available parameters and their display status.

Details on safety certifications like SIL, CE Mark, and ATEX.

Comprehensive list of certifications for various hazardous area types.

Installation diagrams and entity parameters for intrinsic safety.

Entity parameters and diagrams for Fieldbus and PROFIBUS protocols.

Contact details for application assistance, sales, and support.

Honeywell's warranty policy and customer recourse for defective products.

The Honeywell SmartLine Pressure Transmitter ST 700 Basic is a robust and versatile device designed for measuring Differential Pressure (DP), Gauge Pressure (GP), and Absolute Pressure (AP) in various industrial applications. This quick start safety installation guide provides essential information for its setup and initial operation.

The ST 700 Basic SmartLine Pressure Transmitter operates on a two-wire power/current loop, providing an analog output signal that corresponds to the measured pressure. It is designed to integrate seamlessly into existing process control systems, offering reliable and accurate pressure measurements. The transmitter can be configured for specific failsafe actions (up-scale or down-scale) and includes a write protect feature to prevent unauthorized changes to its configuration parameters. This ensures operational integrity and safety in critical applications. The device supports HART communication, allowing for remote configuration, diagnostics, and data acquisition using compatible communicators.

The transmitter offers flexible mounting options, including attachment to 2-inch (50 mm) vertical or horizontal pipes using optional angle or flat mounting brackets. For flush-mount models, direct attachment to a process pipe or tank via a 1-inch weld nipple is possible, while models with integral flanges are supported by their flange connection. The transmitter housing can be rotated up to 180 degrees in either direction from the center, allowing for optimal viewing and access after installation.

For applications with small absolute or differential pressure spans, precise leveling of the transmitter is crucial to minimize positional effects on calibration (zero shift). This can be achieved using a spirit balance, particularly for models like STA725 and STA72S, which require vertical mounting. The device's display module provides a standard two-line, six-character LCD for local viewing of process variables and menu navigation. The menu allows access to parameters such as PV display, pressure units, flow units, scaling (low and high), LRV/URV entry, zero correct, DAC zero trim, DAC span trim, loop test, and contrast adjustment. An extended menu can be enabled for more advanced configuration options.

Conduit entry plugs and adapters are provided to ensure environmental ingress protection and compliance with national and local code requirements for hazardous locations. The transmitter accepts up to 16 AWG wire for loop power leads and is not polarity-sensitive, simplifying wiring.

The ST 700 Basic SmartLine Pressure Transmitter is designed for ease of maintenance and long-term reliability. The quick start guide outlines procedures for trimming the transmitter, which is essential for maintaining accuracy, especially after initial installation or when dealing with small differential pressure spans. This involves connecting a tube between the high and low-pressure input connections to eliminate air current effects, applying 24Vdc power, and using a digital voltmeter or applicable communicator to monitor the PV output. The transmitter can then be positioned to achieve a near-zero output reading, and the mounting bolts are tightened. A Zero Correct function, accessible via the local display or communicator, allows for fine-tuning to correct any minor errors after mounting.

For explosion-proof installations, specific precautions are outlined, such as keeping covers tight while energized and disconnecting power before removing end caps for service. The guide emphasizes the importance of replacing temporary plastic dust protectors with suitable cable glands, adapters, or blanking plugs to maintain the specified environmental ingress protection and hazardous location certifications. The modular design, with accessible terminal blocks and jumpers, facilitates easy wiring and configuration adjustments. The device's robust construction and adherence to various certifications (including EMC, ATEX, PED, FM, CSA, INMETRO, IECEx, NEPSI, SAEX, and EAC) ensure its suitability for demanding industrial environments, minimizing the need for frequent maintenance and maximizing operational uptime.

| Series | SmartLine |

|---|---|

| Model | ST700 |

| Output Signal | 4-20mA dc, Digital Communication |

| Process Temperature | -40 to 120°C (-40 to 248°F) |

| Ambient Temperature | -40 to 185°F (-40 to 85°C) |

| Process Connection | 1/2" NPT, 1/4" NPT |

| Housing Material | Aluminum or Stainless Steel |

| Protection | NEMA 4X, IP66/67 |

| Display | LCD with backlight, optional |

| Power Supply | 10.5 to 45 V DC |

| Communication Protocol | HART, FOUNDATION Fieldbus |

| Certifications | ATEX, IECEx, CSA |

Loading...

Loading...