November 2018 Quick Start Installation Guide 3

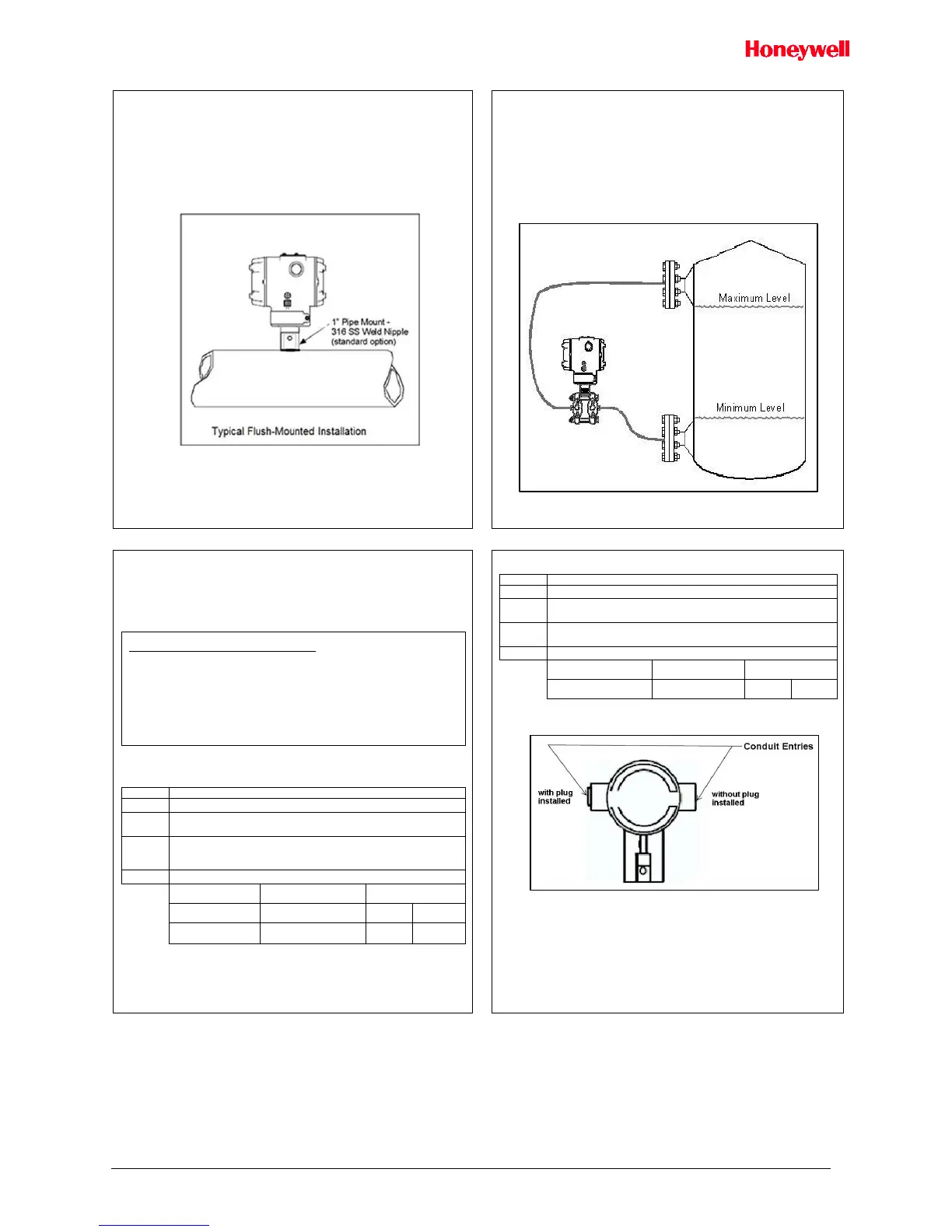

Flush Mounting

To mount a flush mounted transmitter model, cut a hole for a 1-inch standard pipe in the

tank or pipe where the transmitter is to be mounted. See Figure 7.

Weld the 1-inch mounting sleeve to the wall of the tank or to the hole cut on the pipe.

Insert the meter body of the transmitter into the mounting sleeve and secure with the

locking bolt. Tighten the bolt to a torque of 6.4Nm ±0.30Nm [4.7ft.-lbs. ±0.2ft.-lbs.]

Once the transmitter is mounted, the transmitter housing can be rotated to the desired

position. See Figure 7.

Figure 7: Flush Mounting

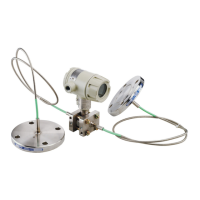

Remote Seal Mounting

Mount the transmitter at a remote distance determined by length of capillary tubing.

Note: The combination of tank vacuum and high pressure capillary head effect should

not exceed 9psi (300mm Hg) absolute.

On insulated tanks, remove enough insulation to accommodate the mounting sleeve.

Figure 8 Example – Typical Remote Seal Transmitter installation.

Note: For Sanitary 3-A installations, only mount the transmitter outside of the Non-

Product Contact area where incidental contact with the process material is unlikely,

use a minimum capillary length of 1.5m (5ft.)

Figure 8: Remote Seal mounting

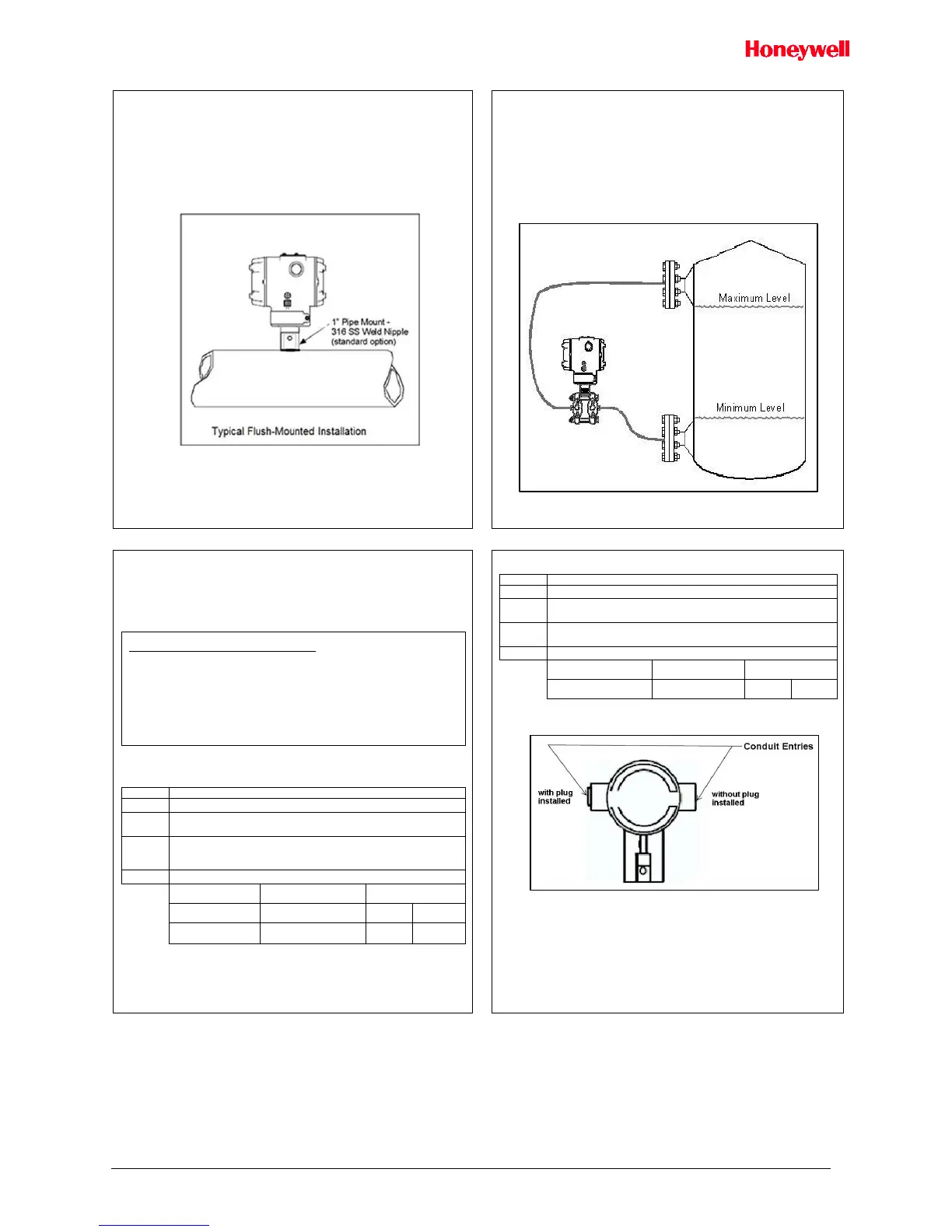

Conduit Entry Plugs and Adapters

Procedures

It is the User/Installer’s responsibility to install the Transmitters in accordance with

national and local code requirements. Conduit entry plugs and adapters shall be

suitable for the environment, shall be certified for the hazardous location when required

and acceptable to the authority having jurisdiction for the plant.

CONDUIT ENTRY PRECAUTIONARY NOTICE

THE CONDUIT/CABLE GLAND ENTRIES OF THIS PRODUCT ARE SUPPLIED

WITH PLASTIC DUST CAPS WHICH ARE NOT TO BE USED IN SERVICE.

IT IS THE USER’S RESPONSIBILITY TO REPLACE THE DUST CAPS WITH

CABLE GLANDS, ADAPTORS AND/OR BLANKING PLUGS WHICH ARE

SUITABLE FOR THE ENVIRONMENT INTO WHICH THIS PRODUCT WILL BE

INSTALLED. THIS INCLUDES ENSURING COMPLIANCE WITH HAZARDOUS

LOCATION REQUIREMENTS AND REQUIREMENTS OF OTHER GOVERNING

AUTHORITIES AS APPLICABLE.

Use the following procedures for installation:

Table 1 - Conduit Entry Plugs

Remove the protective plastic cap from the threaded conduit entry.

To ensure the environmental ingress protection rating on tapered

threads (NPT), a non-hardening thread sealant may be used.

Thread the appropriate size conduit plug (M20 or ½” NPT) into the

conduit entry opening. Do not install conduit entry plugs in conduit entry

openings if adapters or reducers will be used.

Tighten adapters according to the following table.

Table 2 - Conduit Adapters

Remove the protective plastic cap from the threaded conduit entry.

To ensure the environmental ingress rating on tapered threads (NPT),

a non-hardening thread sealant may be used.

Thread the appropriate size adapter (M20 or ½ NPT) into the conduit

entry opening

Tighten adapters according to the following table.

Figure 9: Electronic Housing Conduit Entries

Note. No plugs come installed in the housings. All housings come with temporary

plastic dust protectors (red) installed and are not certified for use in any installation

Loading...

Loading...