November 2018 Quick Start Installation Guide 4

Wiring Connections and Power Up

Summary

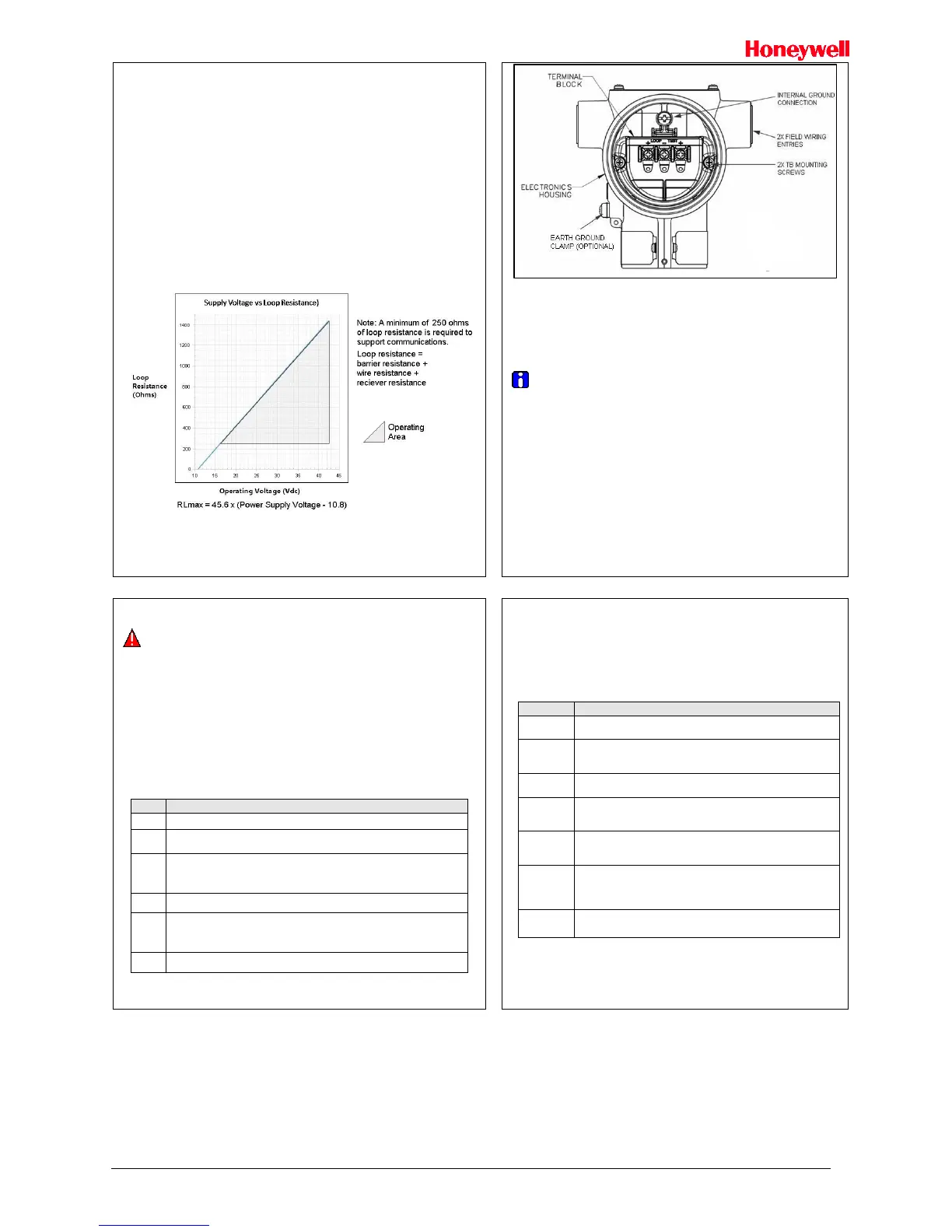

The transmitter is designed to operate in a two-wire power/current loop with loop

resistance and power supply voltage within the operating range shown in Figure 10

Figure 10

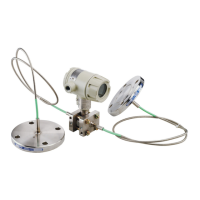

Loop wiring is connected to the transmitter by simply attaching the positive (+) and negative

(–) loop wires to the positive (+) and negative (–) SIGNAL screw terminals on the terminal

block in the transmitter’s electronics housing shown in Figure 11.

Each transmitter includes an internal terminal to connect it to earth ground. Also, a ground

terminal can be optionally added to the outside of the electronics housing. While it is not

necessary to ground the transmitter for proper operation, doing so tends to minimize the

possible effects of noise on the output signal and affords protection against lightning and

static discharge.

An optional lightning terminal block can be installed in place of the non-lightning terminal

block for Transmitters that will be installed in an area that is highly susceptible to lightning

strikes.

Figure 10: Two-wire power/current loop

Figure 11: Terminal Block and Grounding Screw location

Wiring Variations

The above procedures are used to connect power to a Transmitter. For loop wiring

and external wiring, detailed drawings are provided for Transmitter installation in

non-intrinsically safe areas and for intrinsically safe loops in hazardous area locations.

This procedure shows the steps for connecting power to the transmitter.

Wiring must comply with local codes, regulations and ordinances. Grounding

may be required to meet various approval body certification, for example CE

conformity. Refer to the ST 700 SmartLine Transmitter User’s Manual,

Documents # 34-ST-25-44 for details.

Explosion-Proof Conduit Seal

When installed as explosion proof in a Division 1 Hazardous Location, keep covers

tight while the Transmitter is energized. Disconnect power to the Transmitter in the

non-hazardous area prior to removing end caps for service.

When installed as non-incendive equipment in a Division 2 hazardous location,

disconnect power to the Transmitter in the non-hazardous area, or determine that the

location is non-hazardous before disconnecting or connecting the Transmitter wires.

Transmitters installed as explosion proof in Class I, Division 1, Group A Hazardous

(classified) locations in accordance with ANSI/NFPA 70, the US National Electrical Code,

require a LISTED explosion proof seal to be installed in the conduit, within 18 inches

(457.2mm) of the Transmitter. Crouse-Hinds type EYS/EYD or EYSX/EYDX are examples

of LISTED explosion proof seals that meet this requirement. Transmitters installed as

explosion proof in Class I, Division 1, Group B, C or D hazardous (classified) locations do

not require that explosion proof seal be installed in the conduit.

See Figure 11, above, for parts locations.

Remove the end cap cover from the terminal block end of the Electronics

Housing

Feed loop power leads through one end of the conduit entrances on

either side of the Electronics Housing. The Transmitter accepts up to 16

AWG wire.

Plug the unused conduit entrance as specified in Table 1.

Connect the positive loop power lead to the positive (+) terminal and the

negative loop power lead to the negative (-) terminal. Note that the

Transmitter is not polarity-sensitive.

Replace the end cap, and secure it in place using a 1.5mm hex wrench.

Trim the Transmitter

Procedure to Trim the Transmitter

For a transmitter with a small differential pressure span, you must ensure that the

transmitter is vertical when mounting it. You do this by leveling the transmitter side-

to-side and front-to-back. See Figure 5 for suggestions on how to level the

transmitter using a spirit balance. You must also zero the transmitter by following

the steps in this table.

Attach the transmitter to the mounting bracket but do not

completely tighten the mounting bolts

Connect a tube between the input connections in the high

pressure (HP) and low pressure (LP) heads to eliminate the

effects of any surrounding air currents.

Connect 24Vdc power to the transmitter. Connect a digital

voltmeter to monitor the PV output.

Use applicable communicator to establish communications with

the transmitter. For HART, use MCT or other HART

Communicator with applicable Honeywell DD's.

While reading the transmitter’s output on a communication tool

or a voltmeter, position the transmitter so the output reading is

at or near zero, and then completely tighten the mounting bolts.

The Local Display or applicable communicator can be used to

perform the Zero Corrects. This corrects the transmitter for any

minor error that may occur after the mounting bolts are

tightened.

Remove the tube from between the input connections, the

power, and the digital voltmeter or communication tool.

Loading...

Loading...