November 2018 Quick Start Installation Guide 2

Existing Mounting Bracket

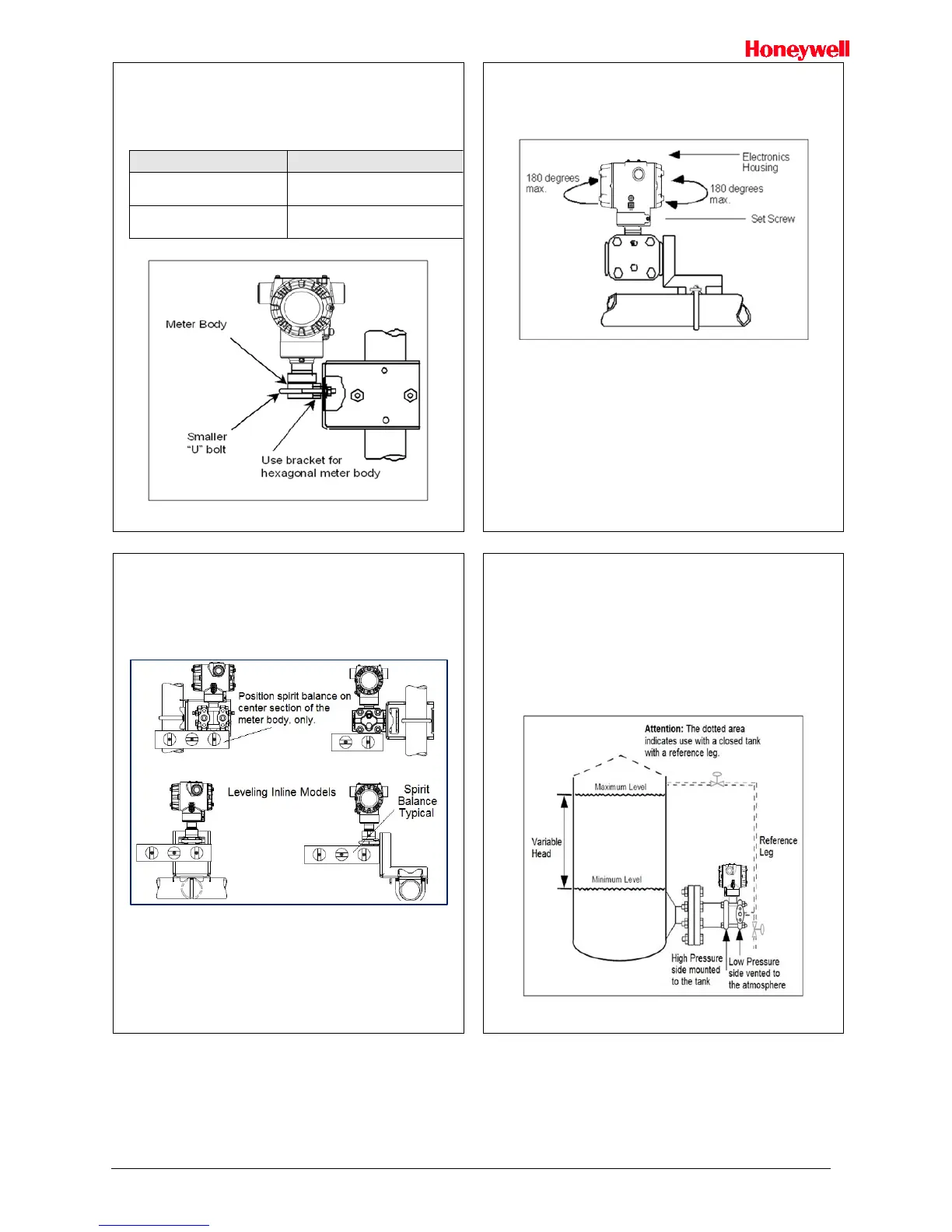

Align appropriate mounting holes in transmitter with holes in bracket and secure with

bolts and washers provided.

Note: If the meter body is hexagonal, you must use the additional bracket supplied.

If meter body is round, discard the bracket.

Example – LGP model transmitter mounted to optional angle mounting bracket.

DP, Dual Head GP, Dual Head AP

and DP Remote Seals.

Use alternate mounting holes in end of

heads.

In-line GP and AP (LGP model) or

GP/AP Remote Seal

Use smaller “U” bolt provided to attach

meter body to bracket. See Figure 3.

Figure 3: LGP and LAP models

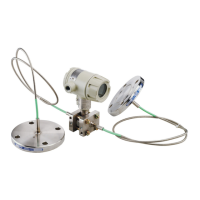

Rotating Transmitter Housing

Loosen set screw on outside neck of transmitter one full turn. Rotate Transmitter

housing in maximum of 180 degree increment in left or right direction from center to

position you require and tighten set screw (1.46 to 1.68Nm/13 to 15lb-in).

Figure 4 Example – Rotating Transmitter Housing.

Figure 4: Rotating Transmitter Housing

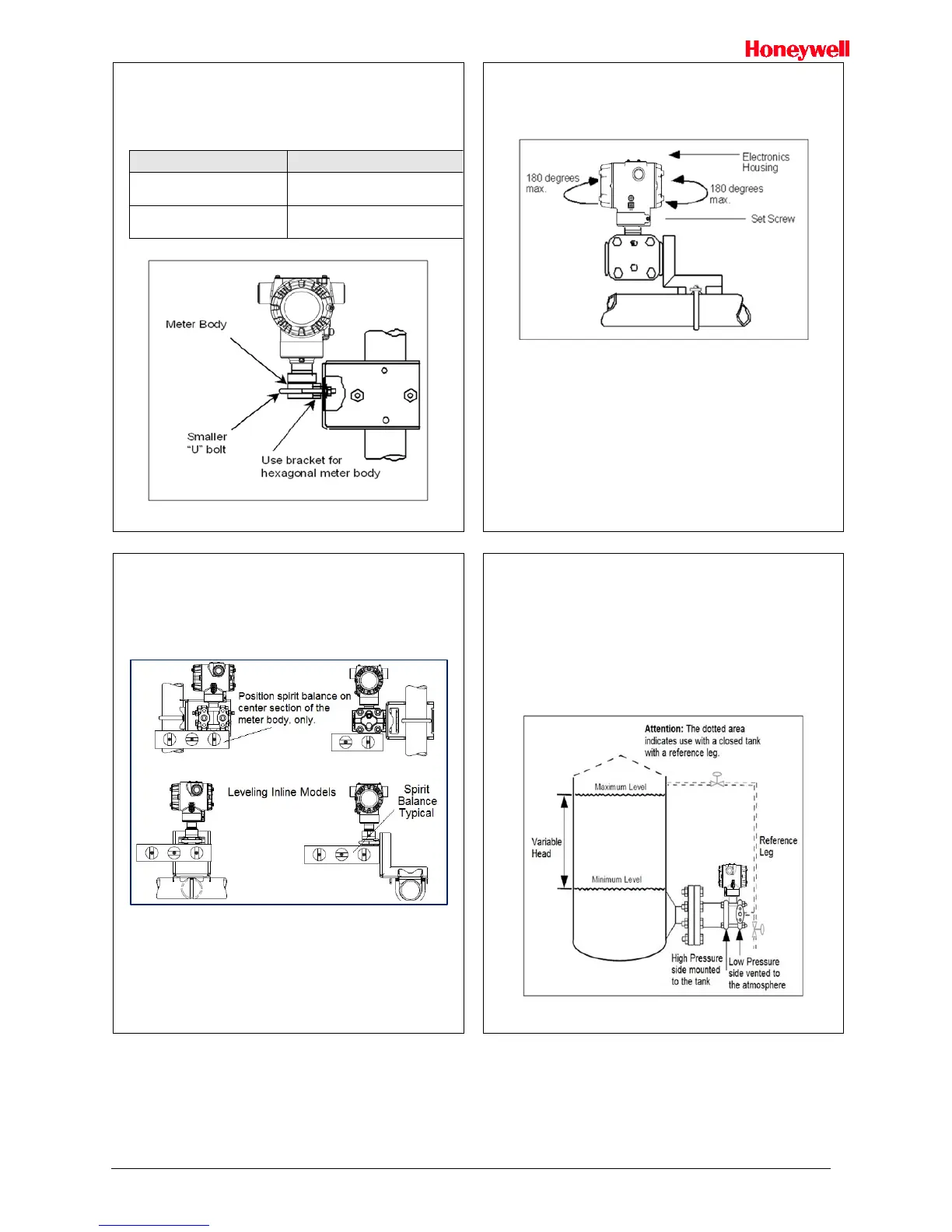

Leveling Transmitters with Small Absolute or Differential Pressure

Spans

Mounting position of these transmitters is critical due to the smaller transmitter spans.

To minimize these positional effects on calibration (zero shift), take the appropriate

mounting precautions that follow for the given transmitter model.

See Figure 5 for suggestions on how to level the transmitter using a spirit balance.

To perform a Zero Trim after leveling, refer to Trim the Transmitter on page 4.

Figure 5: Using level to mount transmitter

For transmitter models STA725 and STA72S you must ensure that the transmitter is

vertical when mounting it. You do this by leveling the transmitter side-to-side and

front-to-back.

Mount transmitter vertically to assure best accuracy. Position the spirit balance on the

pressure connection surface of AP body.

Flange Mounting

To mount a flange mounted transmitter model, bolt the transmitter’s flange to the flange

pipe on the wall of the tank.

On insulated tanks, remove enough insulation to accommodate the flange extension.

It is the End User’s responsibility to provide a flange gasket and mounting hardware that

are suitable for the transmitter’s service condition.

To prevent degradation of performance in Flush-Mounted Flanged Transmitters,

exercise care to ensure that the internal diameter of the flange gasket does not obstruct

the sensing diaphragm.

To prevent degradation of performance in Extended Mount Flanged Transmitters,

ensure that there is sufficient clearance in front of the sensing diaphragm body.

Figure 6: Flange mounting

Loading...

Loading...