SPYDER® LON PROGRAMMABLE, VAV/UNITARY CONTROLLERS

63-2685—03 4

— Hardware driven by the analog current outputs must have a

maximum resistance of 550 Ohms, resulting in a maximum

voltage of 11 volts when driven at 20 mA. If resistance

exceeds 550 Ohms, voltages up to 18 Vdc are possible at

the analog output terminal.

Electrical Shock Hazard.

Can cause severe injury, death or property damage.

Disconnect power supply before beginning wiring or

making wiring connections to prevent electrical shock

or equipment damage.

INSTALLATION

The controller must be mounted in a position that allows

clearance for wiring, servicing, removal, connection of the

LonWorks® Bus Jack, and access to the Neuron® Service Pin

(see Fig. 16 and Fig. 17 on page 14).

The controller may be mounted in any orientation.

IMPORTANT

Avoid mounting in areas where acid fumes or other

deteriorating vapors can attack the metal parts of the

controller, or in areas where escaping gas or other

explosive vapors are present. Fig. 4–Fig. 7 on page 6

for mounting dimensions.

For PVL0000AS, PVL4022AS, and PVL6436AS models, the

actuator is mounted first and then the controller is mounted.

For the other models, go to “Mount Controller” on page 5 to

begin the installation.

Mount Actuator onto Damper Shaft

(PVL0000AS, PVL4022AS, and

PVL6436AS)

PVL0000AS, PVL4022AS, and PVL6436AS controllers include

the direct-coupled actuator with Declutch mechanism, which is

shipped hard-wired to the controller.

The actuator mounts directly onto the VAV box damper shaft

and has up to 44 lb-in. (5 Nm) torque, 90-degree stroke, and

90 second timing at 60 Hz. The actuator is suitable for

mounting onto a 3/8 to 1/2 in. (10 to 13 mm) square or round

VAV box damper shaft. The minimum VAV box damper shaft

length is 1-9/16 in. (40 mm).

The two mechanical end-limit set screws control the amount of

rotation from 12° to 95°. These set screws must be securely

fastened in place. To ensure tight closing of the damper, the

shaft adapter has a total rotation stroke of 95° (see Fig. 1).

NOTES:

1. The actuator is shipped with the mechanical end-

limit set screws set to 95 degrees of rotation.

Adjust the two set screws closer together to

reduce the rotation travel. Each “hash mark” indi-

cator on the bracket represents approximately 6.5°

of rotation per side.

2. The Declutch button, when pressed, allows you to

rotate the universal shaft adapter (see Fig. 1).

IMPORTANT

Determine the damper rotation and opening angle

prior to installation. See Fig. 2 and 3 for examples.

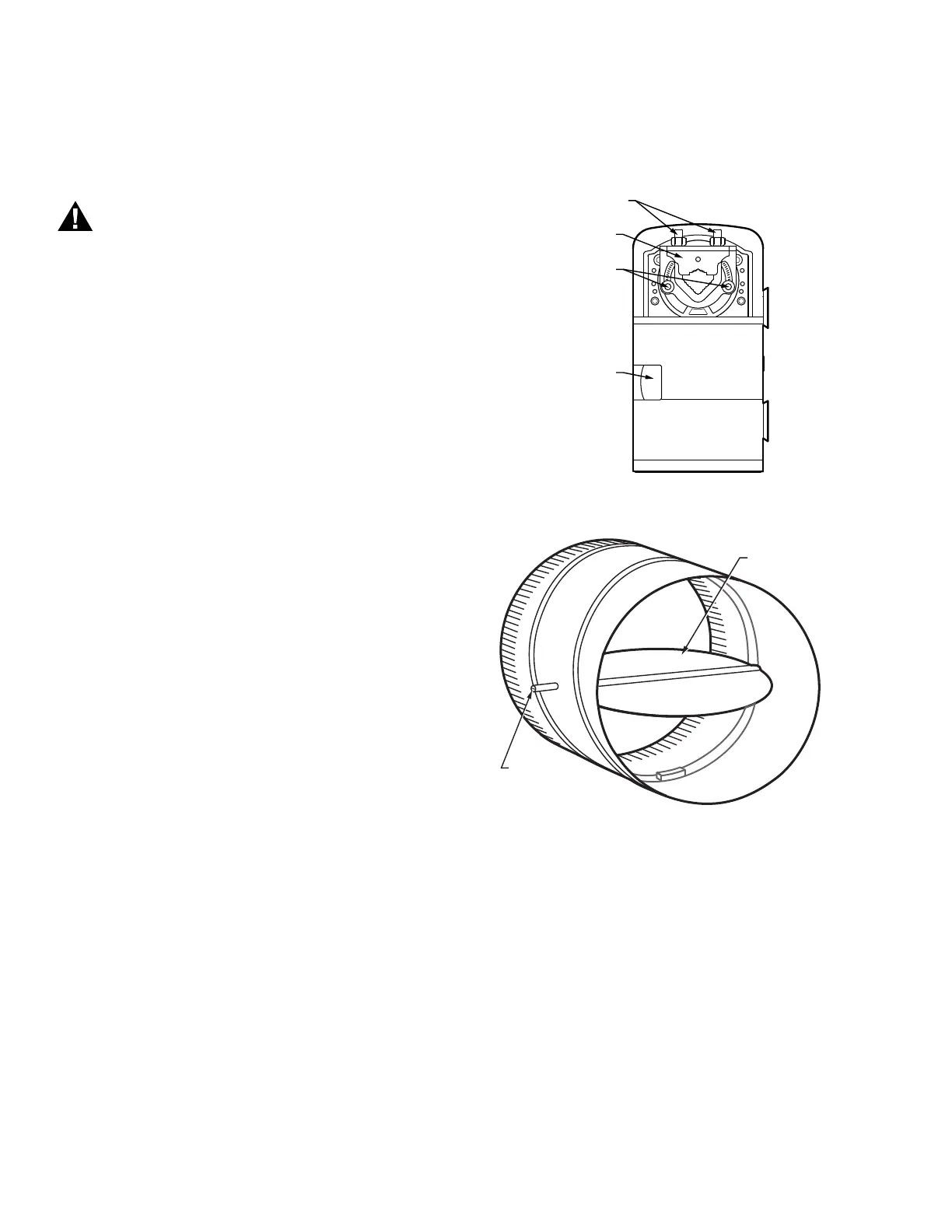

Fig. 1. Series 60 Floating Actuator.

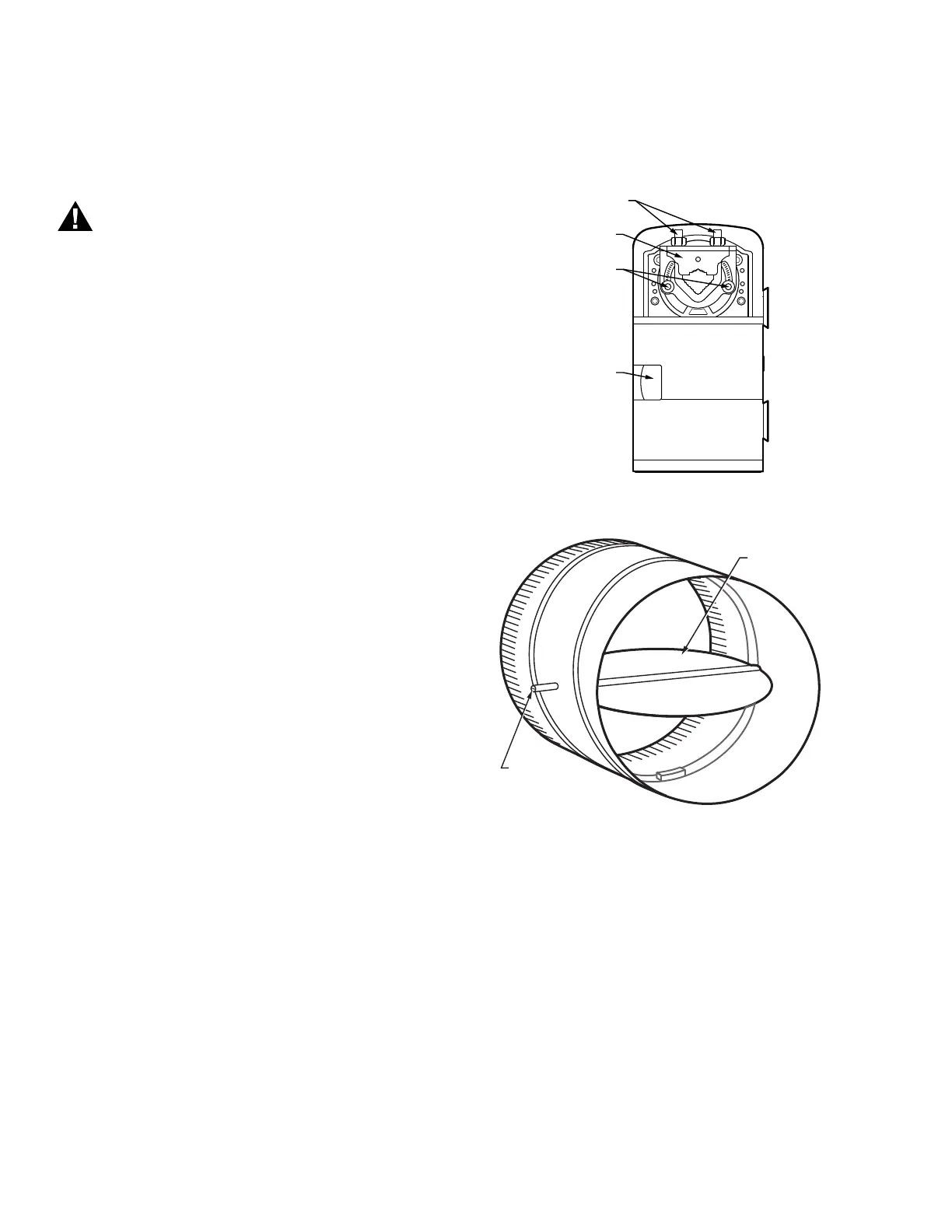

Fig. 2. Damper with 90 degree CW rotation to open.

IMPORTANT

Mount actuator flush with damper housing or add a

spacer between the actuator mounting surface and

damper box housing.

Before Mounting Actuator onto Damper

Shaft (PVL0000AS, PVL4022AS, and

PVL6436AS)

Tools required:

— Phillips #2 screwdriver - end-limit set screw adjustment

— 8 mm wrench - centering clamp

UNIVERSAL SHAFT

CLAMPING BOLTS (2)

M23568

UNIVERSAL

SHAFT ADAPTER

MECHANICAL

END LIMIT SET

SCREWS (2)

DECLUTCH

BUTTON

M23569

DAMPER SHAFT

ROTATES

CLOCKWISE

TO OPEN

DAMPER

Loading...

Loading...