V4730C/V8730C/V4734C 1:1 Gas/Air Servo Regulated Gas Valves

EN2R-9074 0612R1-NE 15

OPERATION

The V4730C/V8730C/V4734C are normally closed valves. The

valves open when energized and close when power is removed.

1. Do not put the system into service until you have satisfactorily

completed the Valve Leak Test, all applicable tests described

in the Checkout section of the instructions for the flame safe-

guard control, and any other tests required by the burner ma-

nufacturer.

2. All tests must be performed by a trained, experienced, flame

safeguard technician.

3. Close all manual fuel shutoff valves immediately if trouble oc-

curs.

After the installation is complete, cycle the valve several times

with the manual fuel shutoff valve cock closed. Make sure the val-

ve functions properly. Also, perform the Valve Leak Test before

putting the valve into service.

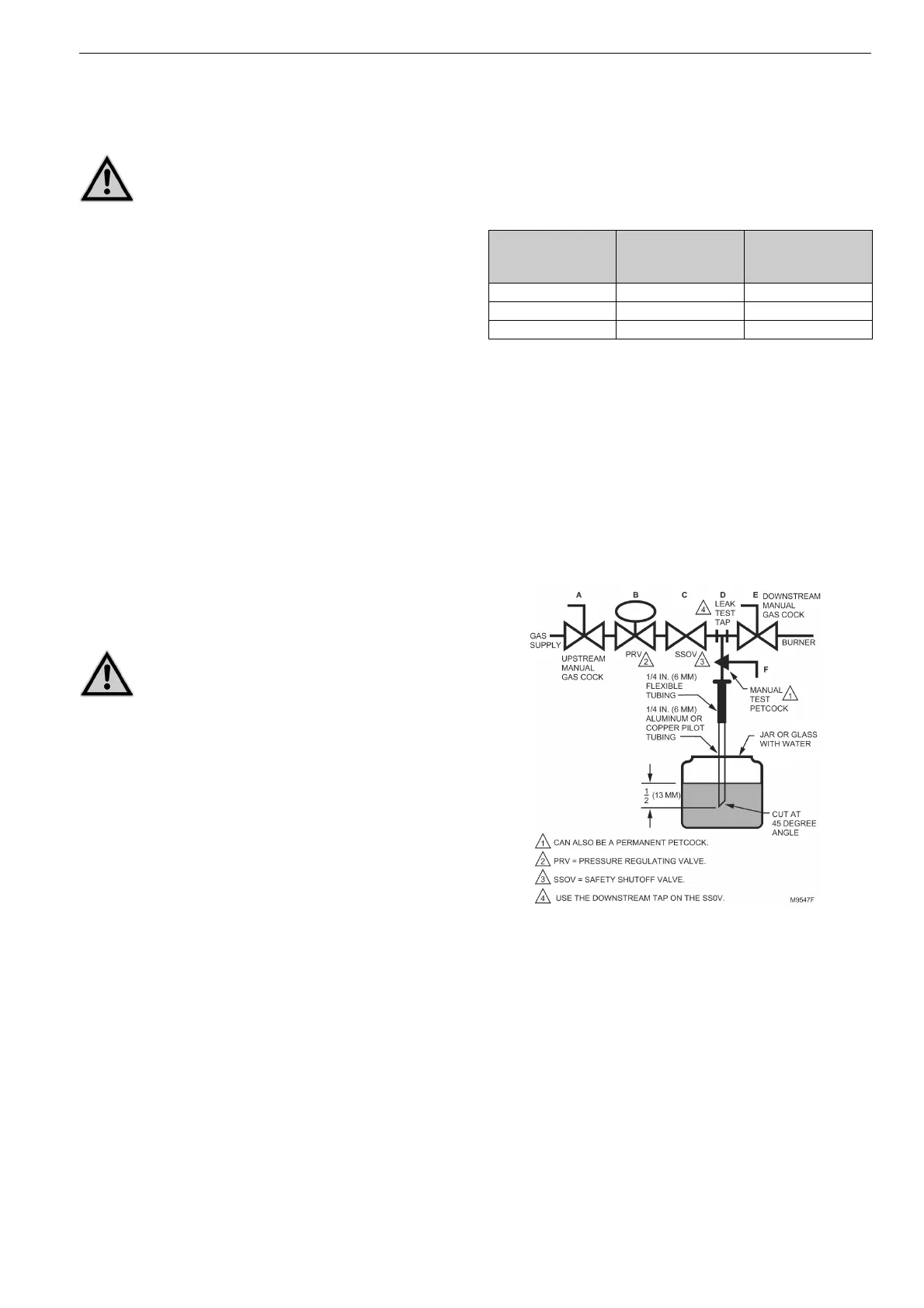

Valve Leak Test (Fig. 19)

This is a test for checking the closure tightness of the gas shutoff

valve. It should be performed only by trained, experienced, flame

safeguard technicians during the initial startup of the burner sys-

tem or whenever the valve is replaced. It is recommended that

this test should also be included in the scheduled inspection and

maintenance procedures. For a periodic inspection test, follow

steps 1, 3, 4, 5, 8, 9, 10, 12, 13, 17, and 18.

1. De-energize the control system to make sure no power goes

to the valves.

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the leak

test tap assembly.

4. To test the first SSOV, remove the 1/8 in. (3mm) NPT plug

from pressure tap point P.

5. Install the leak test tap into pressure tap point P on the valve

body.

6. Open the upstream manual gas cock (A) to repressurize the

first SSOV.

7. Immerse the 1/4 in. (6 mm) tube vertically 1/2 in. (13 mm) in

a jar of water.

8. Slowly open the manual test petcock (F).

9. When the rate of bubbles coming through the water stabili-

zes, count the number of bubbles appearing during a ten-se-

cond period. Each bubble appearing represents a flow rate of

0.001 cfh (28 cch). See Table 4.

10. Close the upstream manual gas cock (A).

11. Remove the leak test tap from the valve body.

12. Using a small amount of pipe sealant on the 1/8 in. (3 mm)

NPT plug, reinstall the plug in pressure tap point P

13. To test the second SSOV, remove the 1/8 in. (3 mm) NPT

plug from the flange pressure tap point 4.

14. Install the leak test tap into pressure tap point 4.

15. Close the downstream manual gas cock (E).

16. Energize the first SSOV

Table 4: max. bubbles per pipe size

17. Immerse the 1/4 in. (6 mm) tube vertically 1/2 in. (13mm) into

a jar of water.

18. Slowly open the manual test petcock (F).

19. When the rate of bubbles coming through the water stabili-

zes, count the number of bubbles appearing during a ten-se-

cond period. Each bubble appearing during a 10-second

period represents a flow rate of 0.001 cfh (28 cch).

See Table 4.

20. De-energize First SSOV

21. Remove the leak test tap from the valve body.

22. Using a small amount of pipe sealant on the 1/8 in. (3 mm)

NPT plug, reinstall the plug in pressure tap point 4.

Fig. 19: Valve leak test

After the Test

1. . Make sure the downstream manual gas cock (E) is closed.

2. Open the upstream manual gas cock (A) and energize the

valve through the safety system.

3. Test with rich soap and water solution to make sure there is

no leak at the test tap (D) or any pipe adapter/valve mating

surfaces.

4. De-energize the valve (C).

5. Open the downstream manual gas cock (E).

6. Restore the system to normal operation.

WARNING

Explosion and Electrical Shock Hazard. Can cau-

se severe injury, death or property damage.

WARNING

Electrical Shock Hazard. Can cause severe injury

or death.

Remove the power from the system before beginning

the valve leak test to prevent electrical shock. More

than one disconnect may be involved.

Pipe Size (in. NPT) Maximum Seat

Leakage (UL)

Maximum Number

of Bubbles in 10

seconds

1/2 - 3/4 235 cch 6

1 275 cch 7

1 - 1/4 340 cch 8

Loading...

Loading...