Region: Global AP040390 REV1.2 This Installation Guide is applicable to 1600/1800/2000/1600B/1800B/2000B-4T microinverters

© 2021 Hoymiles Power Electronics Inc. All rights reserved.

01

2. Installation Steps

1. Accessories

Step 1. Plan and install the Microinverter

All accessories above are not included in the package and should be purchased separately.

Note:

1. Install the microinverter and all DC connections under the PV module to avoid direct sunlight, rain exposure, snow buildup, UV, etc.

2. Leave at least 2 cm of space around the microinverter enclosure to ensure ventilation and heat dissipation.

3. Mounting torque of the 8 mm screw should be 9 N·m. Please do not over-torque.

The order of Step 1 and Step 2 can be reversed according to your planned needs.

Item Description

A AC Trunk Cable, 12/10 AWG Cable

B M8*25 screws (Prepared by the installer)

C AC Trunk Connector

D AC Trunk Port Cap

E AC Trunk Port Disconnect Tool

F AC Trunk End Cap

G AC Trunk Connector Unlock Tool

- Use the AC Trunk Connector Unlock Tool to

unlock the connector upper cover.

1 ) Disassemble the AC Trunk Connector and remove the cable.

2 ) Install the AC Trunk End Cap at one side of AC Trunk Cable (The end of AC Trunk Cable)

3 ) Install AC end cable on the other side of AC Trunk Cable (connected to the distribution box)

- Loosen the three screws with screwdriver.

Untighten the cap and remove the cable.

*Note:

HMS-1600/1800/2000-4T Quick Installation Guide

FA B C E GD

A ) Mark the position of each microinverter on the rail, according to the PV module layout.

Step 2. Plan and build the AC Bus Cable

AC Trunk Cable is used to connect the microinverter to distribution box.

A ) Select the appropriate AC Trunk Cable according to the spacing between microinverters. The connector spacing of

the AC Trunk Cable should be close to spacing between microinverters to ensure that they are well-matched. (Hoymiles

provides AC Trunk Cable with different AC Trunk Connector spacing.)

B ) Determine how many microinverters you plan to install on each AC branch and prepare AC Trunk Connectors

accordingly.

C ) Take out segments of AC Trunk Cable as you need to make AC branch.

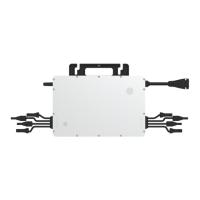

B ) Fix the screw on the rail.

C ) Hang the microinverter on the

screws, and tighten the screws. The silver

cover side of the microinverter should be

facing the panel.

- Insert the AC Trunk End cap and screw the

cap back to port, then tighten the cap.

- Unlock the port upper cover, loosen the screws

with screwdriver and remove the extra cable.

(Skip this step if there is no cable at this side.)

- Plug the upper cover back to the Trunk

connector.

4.0±0.5N·m

Mounting Torque : 9 N·m

click