Preventive Maintenance 603

Preventive Maintenance

completely of any dried ink, until the swaps used to clean it, do not show any indication of ink present on

the window.

1. Unload the substrate.

2. Turn of the printer and wait for it to cool down.

3. Wipe the sensor with one of the cotton swabs provided in the User Maintenance Guide kit, slightly

dampen with Methyl acetate to remove dried ink from the sensor window.

4. If the sensor window is heavily coated with dried ink, you may need to apply some pressure while

wiping, helping the cotton to absorb the ink. Continue cleaning with fresh swabs until the cotton

stays clean and the sensor window looks clean. When reflecting ambient light, a clean sensor shows

a blue-colored reflection that should extend uniformly across its whole surface. You can see this

reflection by moving closer and slightly changing your angle of view.

5. Methyl Acetate is a flammable liquid, after the cleaning procedure has finished, remove the liquid

and the cloth away from the vicinity of the printer.

6. Wait three or four minutes to let the liquid evaporate, before turning on the printer

Applying Oil to the Platen rollers

Occasionally, it maybe necessary to oil the Overdrive in order to stop the rollers from squeaking:

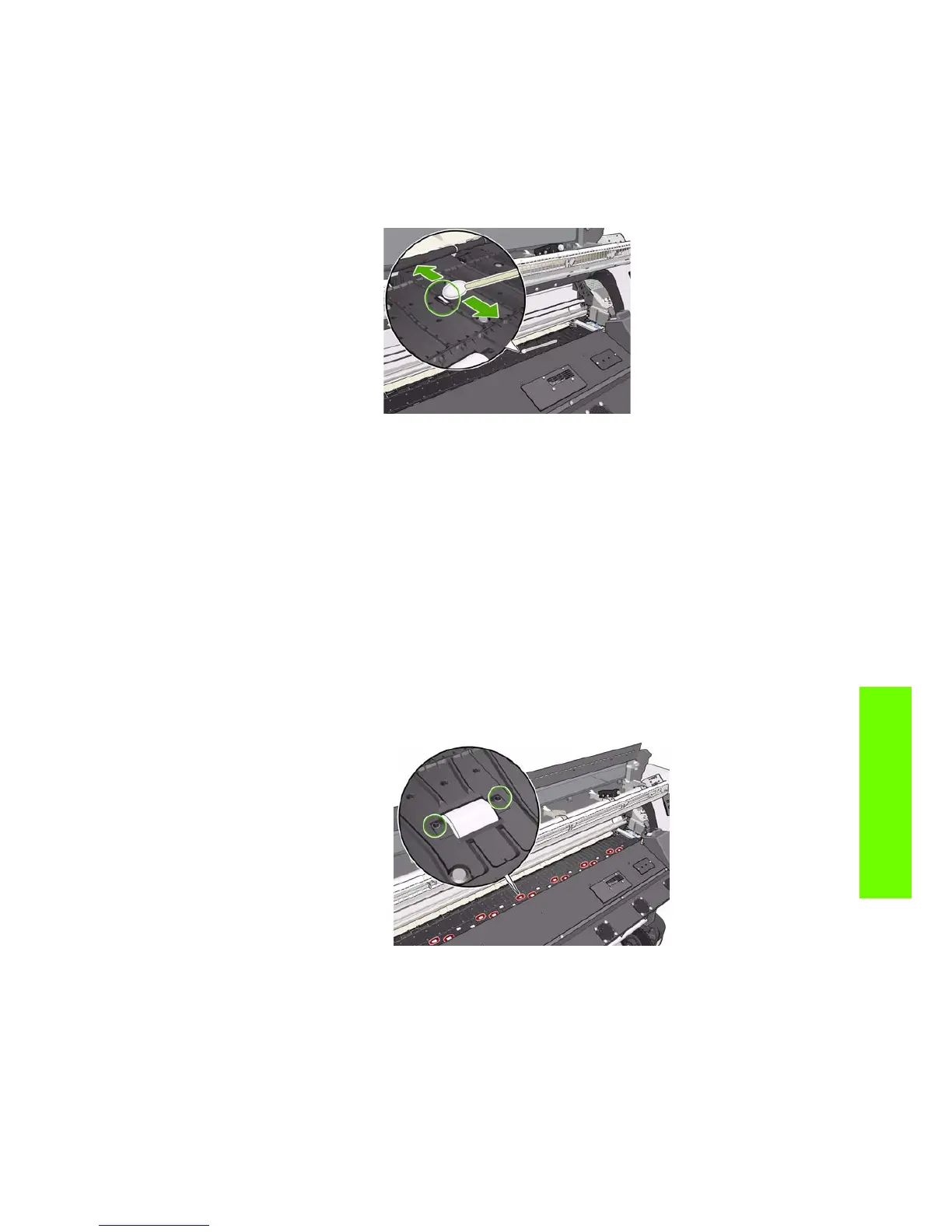

1. Unlock and open the Window.

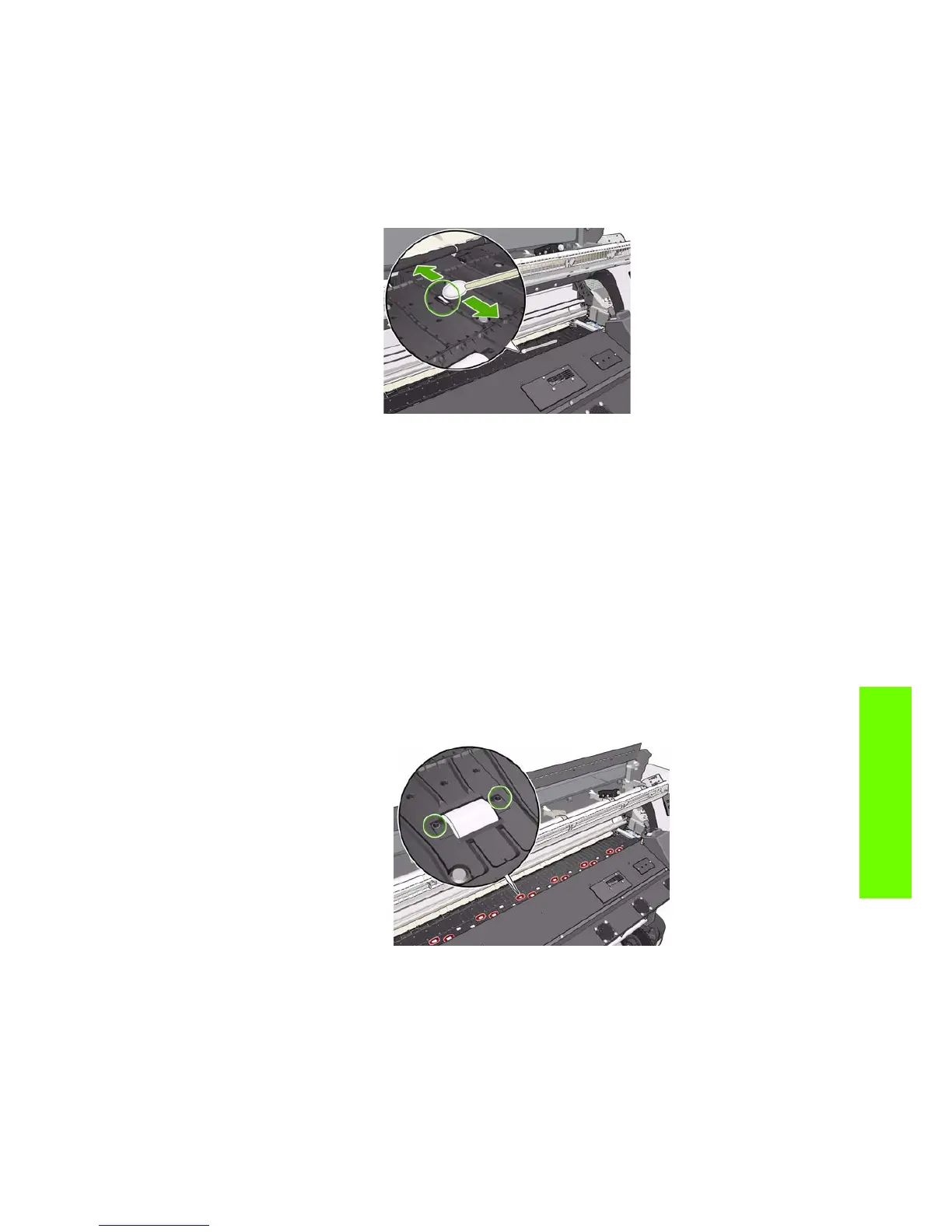

2. Locate the small holes in the platen near some of the rollers.

Loading...

Loading...