15

3585 Series Hydraulic Installation Tools (HK1080) Howmet Fastening Systems

TROUBLESHOOTING

1. Tool fails to operate when trigger is pressed.

a. Inoperative Powerig

®

Hydraulic Unit. See

applicable instruction manual.

b. Loose air or electric connections.

d. Loose or faulty hydraulic hose couplings.

e. ump valve not installed in tool.

2. Tool operates in reverse.

a. Reversed hydraulic hose connections between

hydraulic unit and tool.

at tool.

a. Hydraulic unit not operating properIy.

b. ump valve installed incorrectly.

c. Powerig Hydraulic Unit running in reverse (918:

918-5). See unit’s manual.

6. Tool operates erratically and fails to properly

install fastener.

a. Low or erratic hydraulic pressure; air in system.

c. ump valve installed incorrectly.

d. Excessive wear on sliding surfaces of tool parts.

e. Excessive wear of dump valve in tool.

7. Pull grooves on fastener pintail stripped during

PULL stroke.

fastener pintail.

b. Incorrect fastener grip.

d. Metal particles in jaw segments pull grooves.

e. Excessive sheet gap.

8. Collar of HuckBolt

®

Fastener not completely

swaged.

a. Improper tool operation. See Trouble 6.

b. Scored anvil.

9. Shear collar on HUCK Blind Fastener not driven.

a. Improper tool operation.

10. Tool “hangs-up” on swaged collar of HuckBolt

Fastener.

a. Improper tool operation. See Trouble 6.

11. Pintail of fastener fails to break.

a. Improper tool operation. See Trouble 6.

b. Pull grooves on fastener are stripped. See

Trouble 7.

c. PULL pressure too low.

dump valve.

good parts for suspected defective parts. Use this Troubleshooting information to aid in locating and correcting trouble.

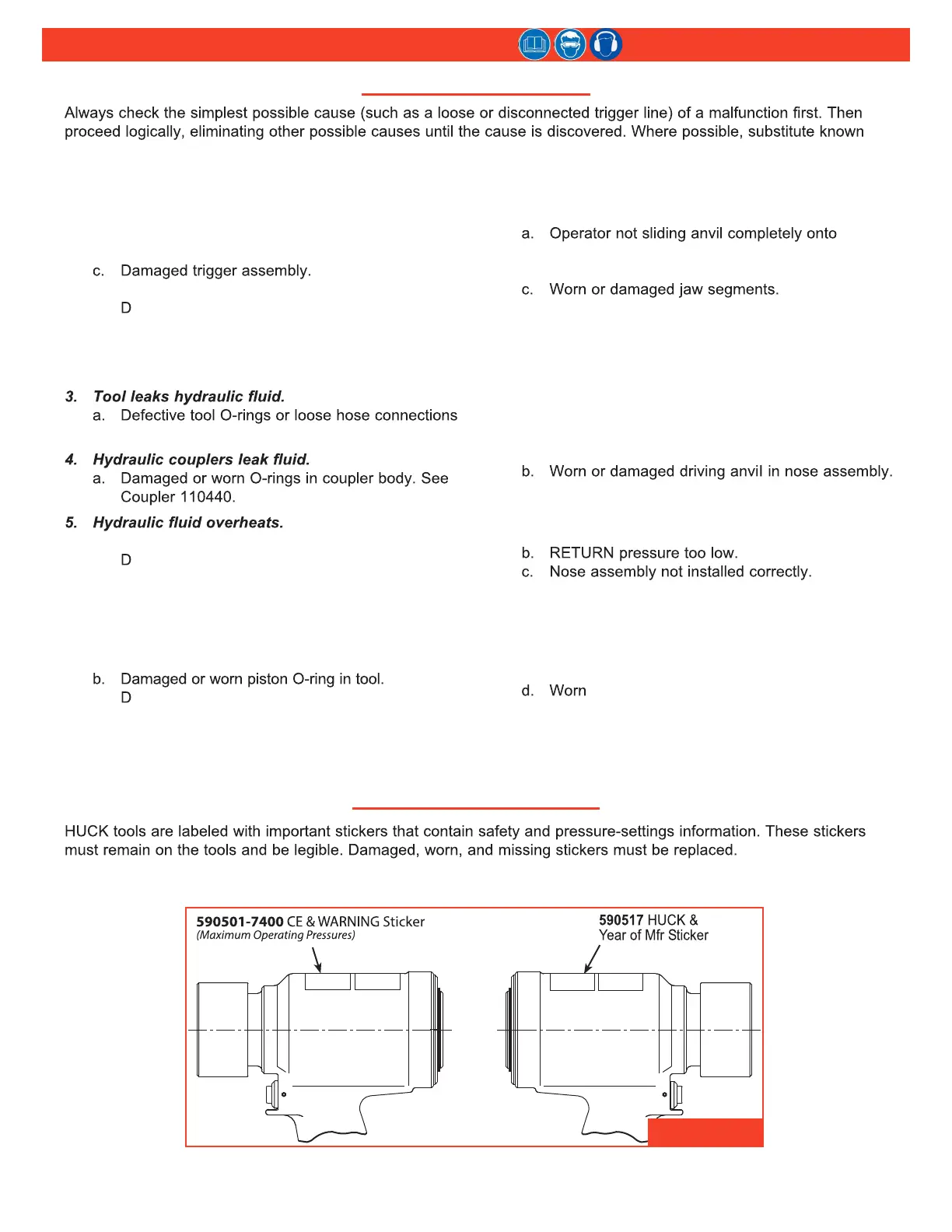

Sticker locations

and part numbers are shown below. A sticker must be ordered and replaced on the tool, in the location shown, if: i) it

becomes damaged or worn, ii) it has been removed from the tool, or iii) replacing the Cylinder.

STICKER LOCATIONS

FIGURE 5

Loading...

Loading...