10

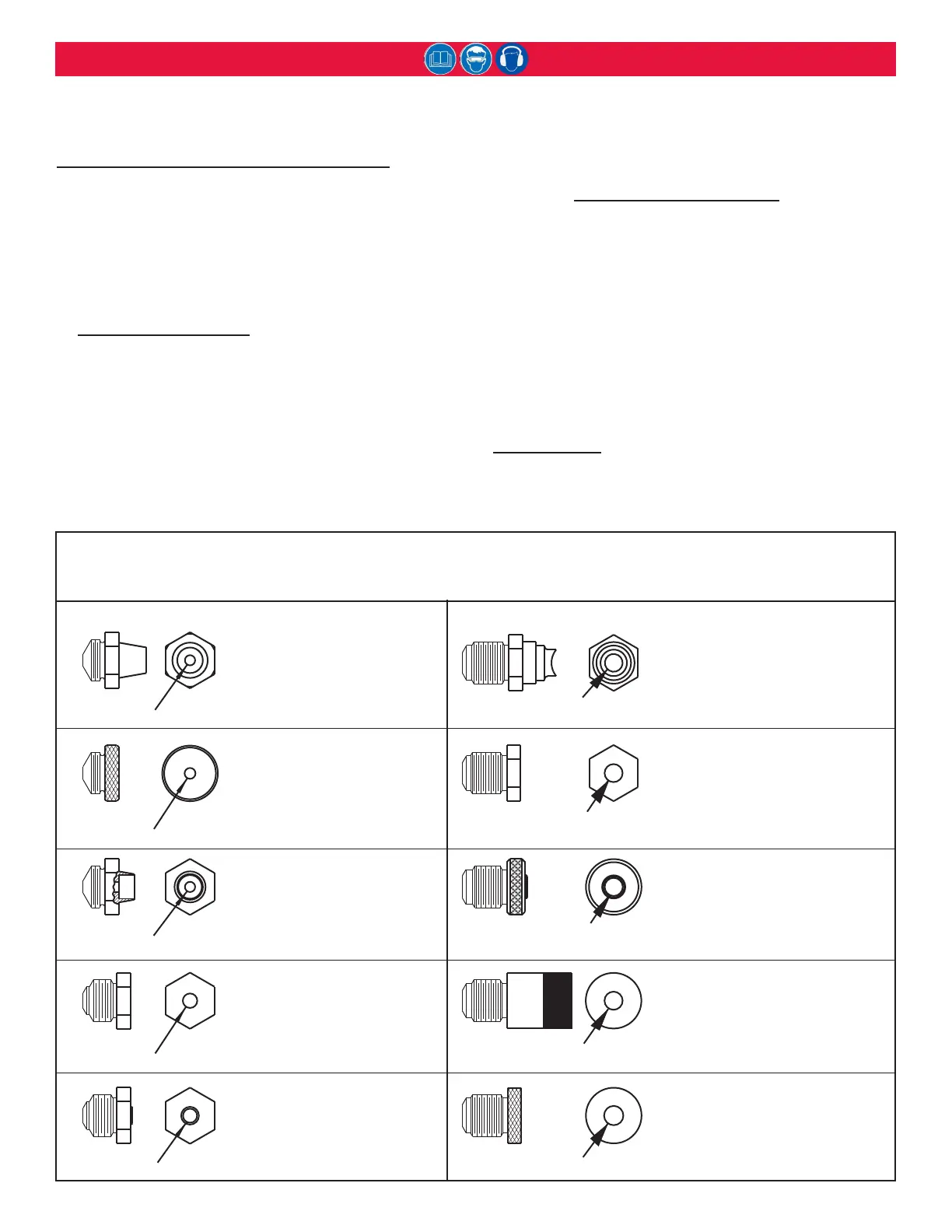

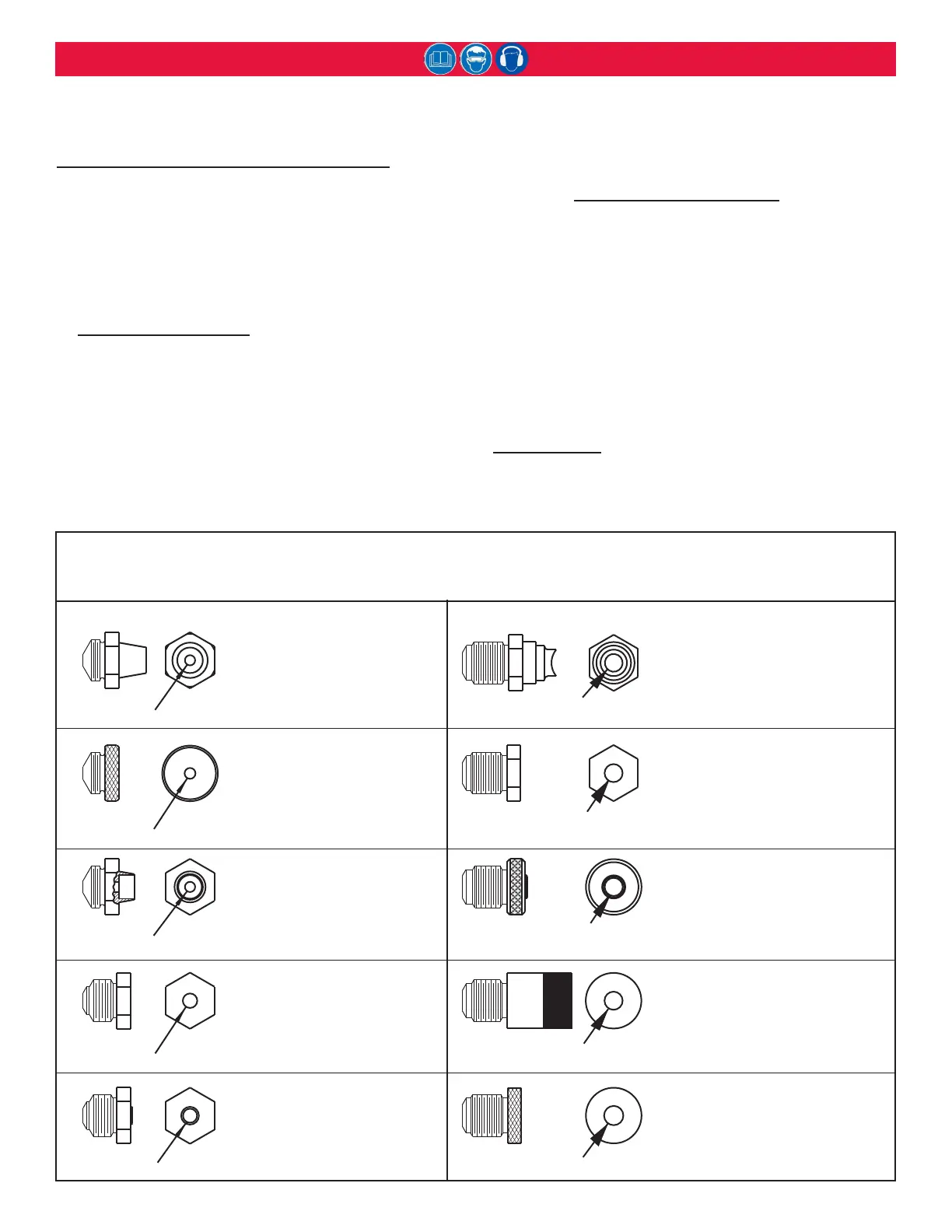

Ø.093

Ø.098

Ø.093

Ø.130

Ø.125

Ø.172

Ø.160

Ø.160

Ø.160

Ø.160

Part No. Description

1/4" Magna Lok

1/4” Pop Rivets

1/4” Plastic Rivets

Replaces Tip 202157

Spec. GM Glass Stop

Travel, Pop Rivets

1/4" Monobolts

1/4" Pop & Plastic

Rivets

1/4" Auto Split "T"

Rivets

3/16" Monobolts

5/32" & 3/16" Pop

& Plastic Rivets

1/8" Stand Off

Pop Rivets

'3/32" & 1/8"

Pop Rivets

1/8" for Trim Molding

Pop Rivets

202142

202193

202169

202157

202155

202168

202158

202190

202159

202156

Part No. Description

Discontinued - Replaced

by tip 202142 (pictured

below)

Steps for Proper Tool Maintenance and Operation

1. Disassemble and clean Nose components periodically or if

the pintails do not drop out freely. Use a pick to clean the

jaw grooves. Wash components in mineral spirits or isopro-

pyl alcohol. Apply a small amount of lubricant to the Jaws

and inside of Jaw Holder prior to assembly.

2. To ease Nose Tube and Nose Piece installation, extend

tool by pumping Handles.

3. Do not use tool as a lever if rivet pintail is jammed

while regripping. Instead, squeeze Handles and press the

Releasing Button while pushing tool nose against work

piece for the jaws to get a deeper grip.

4. If rivet pintail is stuck in tool after breaking, lightly tap

nose against a hard surface while squeezing Handles and

pressing the Releasing Button with tool pointing downward.

Pintail should then fall out.

5. Before operating tool, make sure that all Nose Parts have

been screwed in hand tight.

6. The tool has a 5/8” work travel, the completion of which

is indicated by a solid stop after approximately 12 pumps

(one cycle). Do not force beyond this point to insure

long life of tool.

7. The HK-150 should not be used at temperatures below

35°F unless it is rst brought to room temperature and

cycled several times. Normal use of the tool after warming

should keep it warm enough for proper operation.

8. If tool will not reverse, remove Nose Tube and inspect

for any foreign matter that might have caused jamming

between Jaw Holder and inside of Nose Tube.

9. Frequently check that nose components do not vibrate

loose during operation.

10. Do not rock tool when pumping it. This may cause rivets

to prematurely break.

11. Large fasteners can be set one handed in tight areas by

using short pump strokes.

tool MaIntenance

HK-150 Series Tools (HK1058) Arconic Fastening Systems and Rings

Loading...

Loading...