26 Operator’s Manual

Service Hurricane Power

Search for leaks with a piece of cardboard. Protect

hands and body from high pressure fluids.

IMPORTANT: Check oil level in reservoir tank when

oil is cold.

Do not overfill oil reservoir tank. Oil will expand during

operation and could overflow.

1. Park machine safely.

2. Allow engine to cool.

3. Clean reservoir and cap.

4. Sight through reservoir and ensure oil level is at

the full cold line. If oil is low, add oil to bring oil

level no higher than FULL COLD mark on tank.

NOTE: If oil is above FULL COLD line, drain oil to

proper level.

5. Tighten cap.

Changing Hydraulic Oil and Filters, ZT-3100

Hydro-Gear Hydraulic Oil Filter P/N 425-52114

The transaxles are designed with an external filter for

ease of maintenance. To ensure constant fluid quality

levels and longer life, an initial oil and filter change at

75 hours, then every 400 hours thereafter.

The following procedure can be performed with the

transaxles installed in the machine, and the machine

on level ground.

1. Park machine safely. Engage the parking brake.

2. Allow engine and transaxles to cool.

3. Jack machine up from rear. Use blocking to sup-

port machine.

4. Remove both rear tires. Apply the bypass valves

for both transaxles.

CAUTION: Skid plate is heavy.

5. Remove six 3/8-16 x 3/4 bolts that fasten skid

plate in position.

Use a floor jack to support the skid plate. Lower

jack and remove from under unit.

6. Remove toe kick to access the hydraulic filters,

set aside.

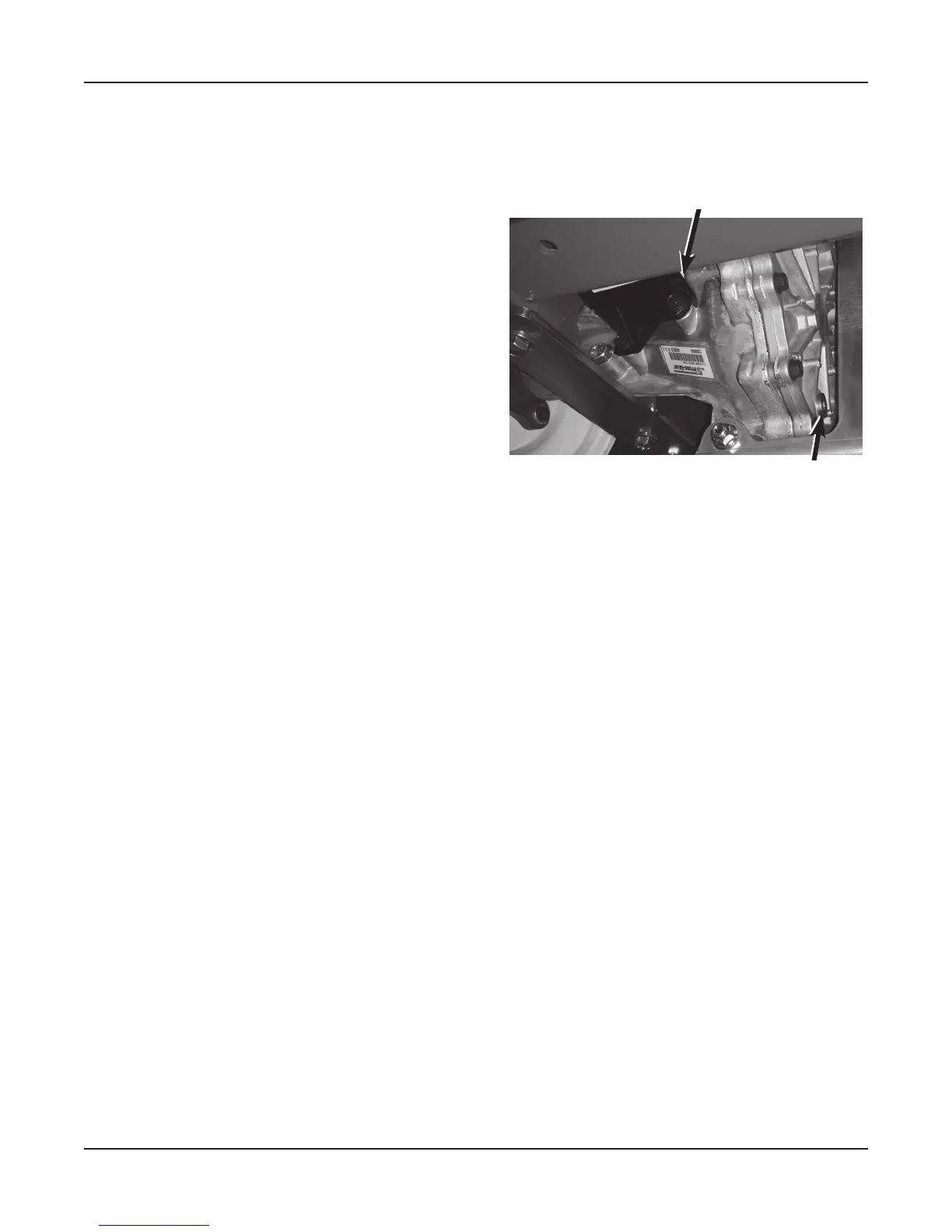

Hydraulic Oil Filter

(Not Visible Behind Filter Guard)

Drain Plug

Transaxle Drain Plug and Hydraulic Oil Filter.

7. Remove the three filter guard screws and filter

guard. Clean any loose debris from around the

perimeter of the filter. Place drain pan beneath

the oil filter.

8. Remove the oil filter from the transaxle. Dispose

of used filter properly.

9. Remove the drain plug from the transaxle, allow

all fluid to drain.

10. After the oil has drained, wipe the filter base sur-

face off and apply a film of new oil to the gasket

of the new replacement filter.

11. Replace the drain plug.

12. Install the new filter by hand, turn 3/4 to one full

turn after the filter gasket contacts the filter base

surface. Do not use a wrench.

13. Re-install the filter guard with three screws.

Torque screws to 65 in. lbs.

14. Repeat steps 8-14 on the opposite side transaxle

drive.

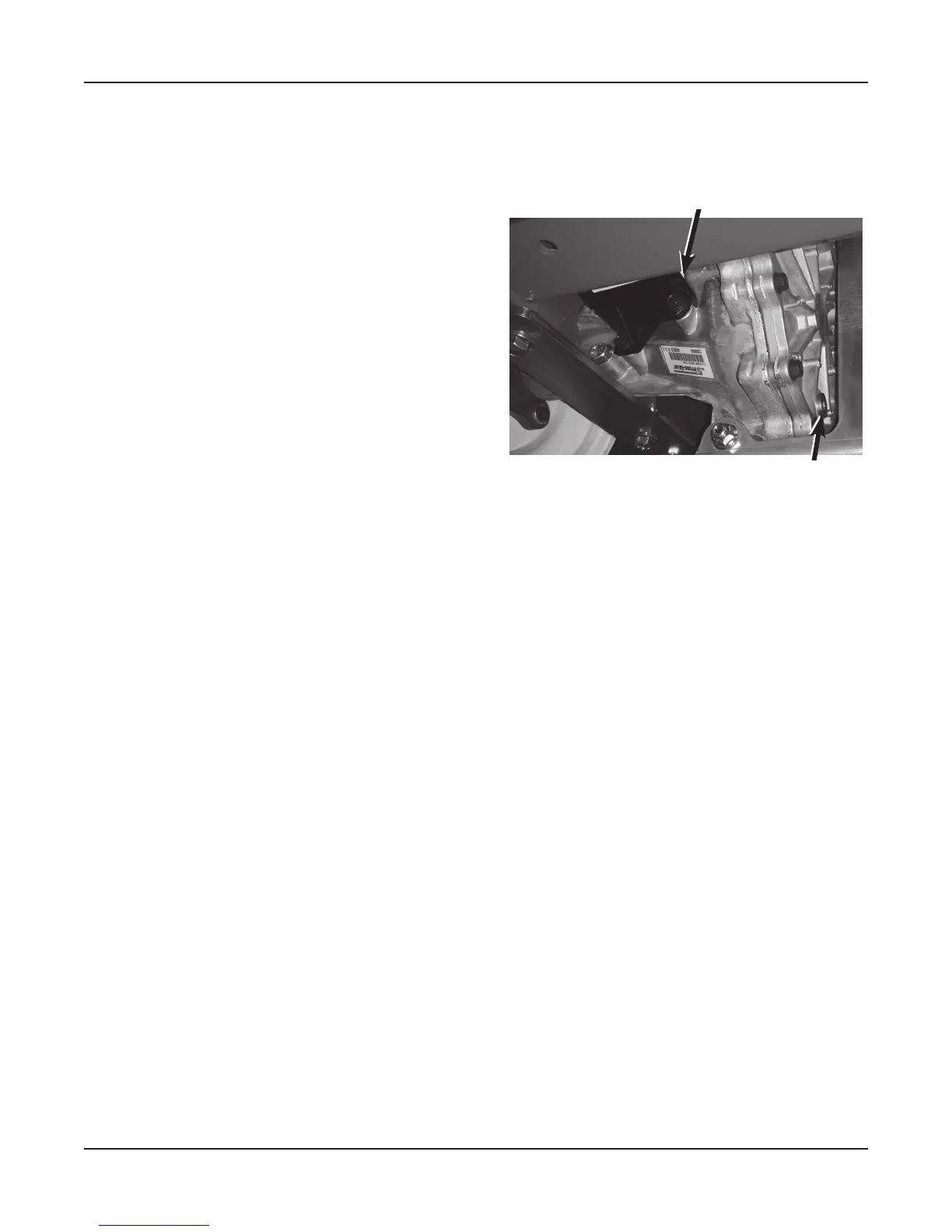

15. Remove the purge port plug from the back of the

transaxle. Refer to Purge Port Plug Location

photo.

Loading...

Loading...