125816 6-3 REV B

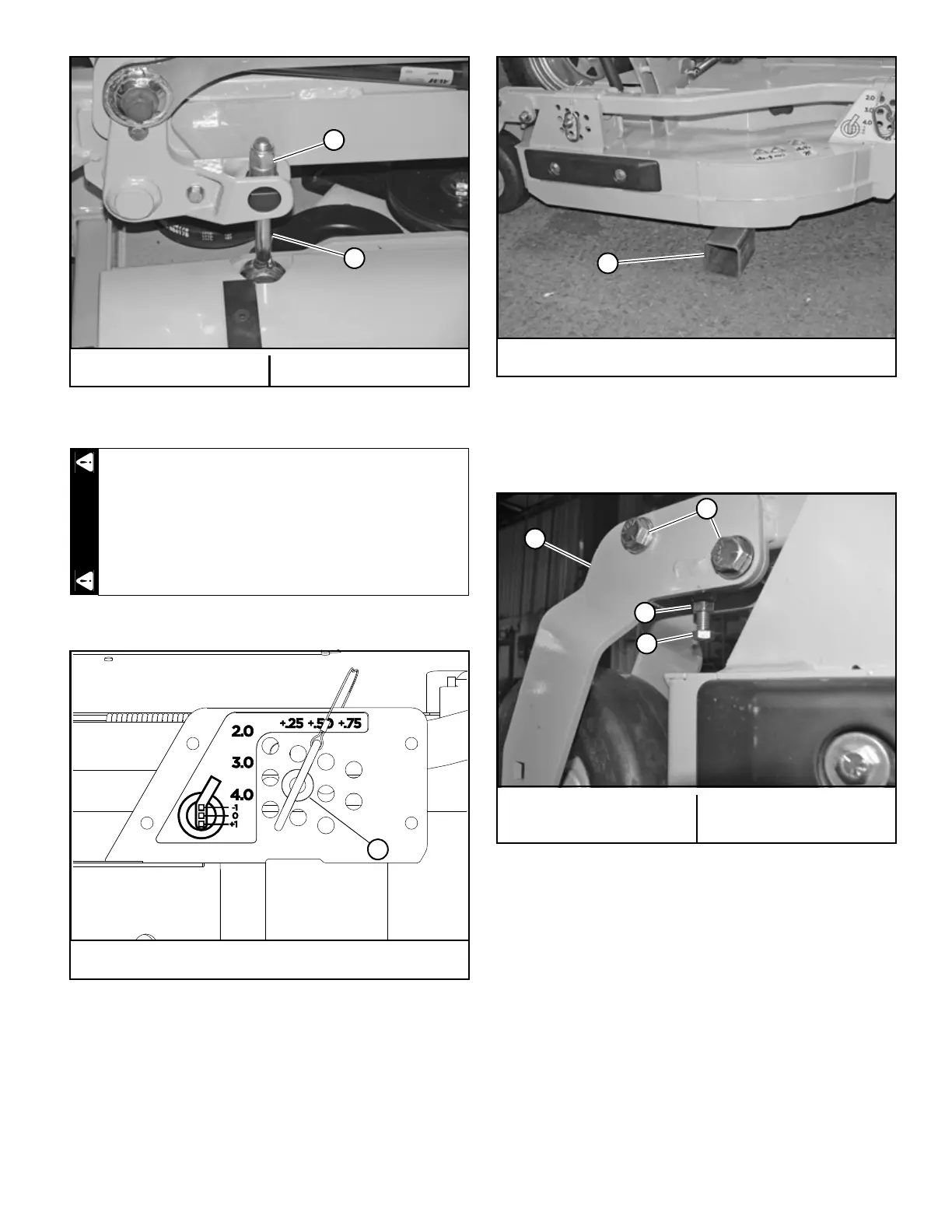

5. Lower the center deck to rest against the stop pin.

6. Set the deck cutting height for the front and rear side

deck gauge wheels at 3-1/4” (82.6 mm). Figure 6-7

7. Place a 3” (76.2 mm) high deck support block (two

stacked 2” x 4” blocks can be used to create a 3”

[76.2 mm] high support) at the outside edge of the side

deck. Figure 6-3 & Figure 6-8

8. Lower the side decks to fully rest on the 3” (76.2 mm)

blocks.

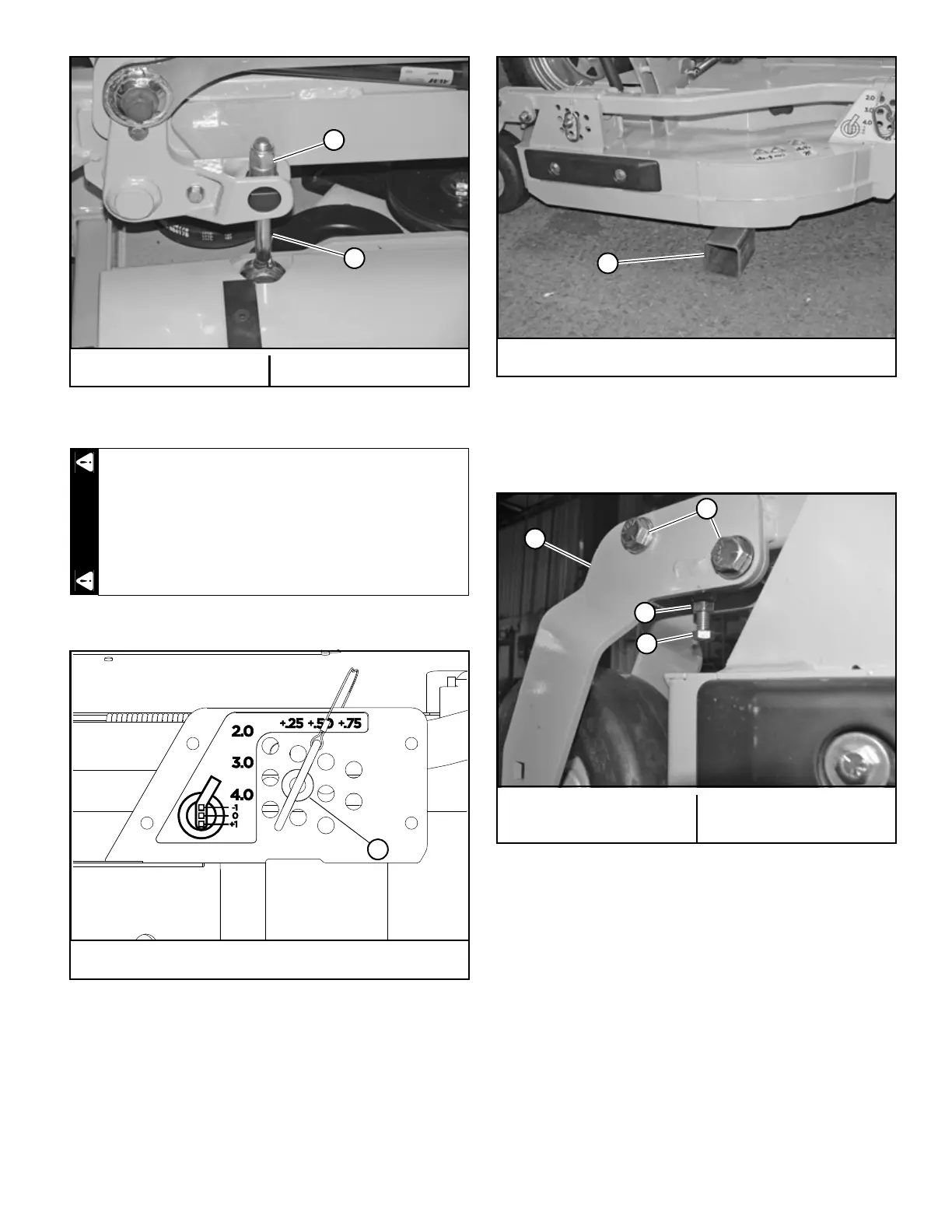

9. Loosen the two 1/2” bolts on the rear gauge wheel

arm. Loosen the jam nut and adjusting bolt so the rear

gauge wheel is not supporting any of the weight of the

side deck. Figure 6-9

10. The front gauge wheel should contact the ground. If

so, skip to Step 11. If not, the gauge wheel will need

adjusted down per Step 12.

11. There should be less than .125” (3.18 mm) gap

between the 3” deck block and the bottom side of the

deck edge. Figure 6-8

If so, go to Step 13. If not, the gauge wheel will need

adjusted up per Step 12.

12. Adjust the front gauge wheel up or down to satisfy

your deck adjustment needs.

Adjustments are made by removing the front wheel

from the wheel tube and re-arranging the two .125”

(3.18 mm) and one .25” (6.35 mm) spacers located

A. Nut B. Deck lift hanger

Figure 6-6

Stop engine. Make sure deck clutch switch is in

the down (OFF) position. Place control levers in the

brake position before leaving machine.

A. Set deck cutting height at 3–1/4"

Figure 6-7

A. 3" (76.2 mm) block

Figure 6-8

A. Rear wheel arm

B. 1/2" bolts

C. Jam nut

D. Adjusting bolt

Figure 6-9

Loading...

Loading...