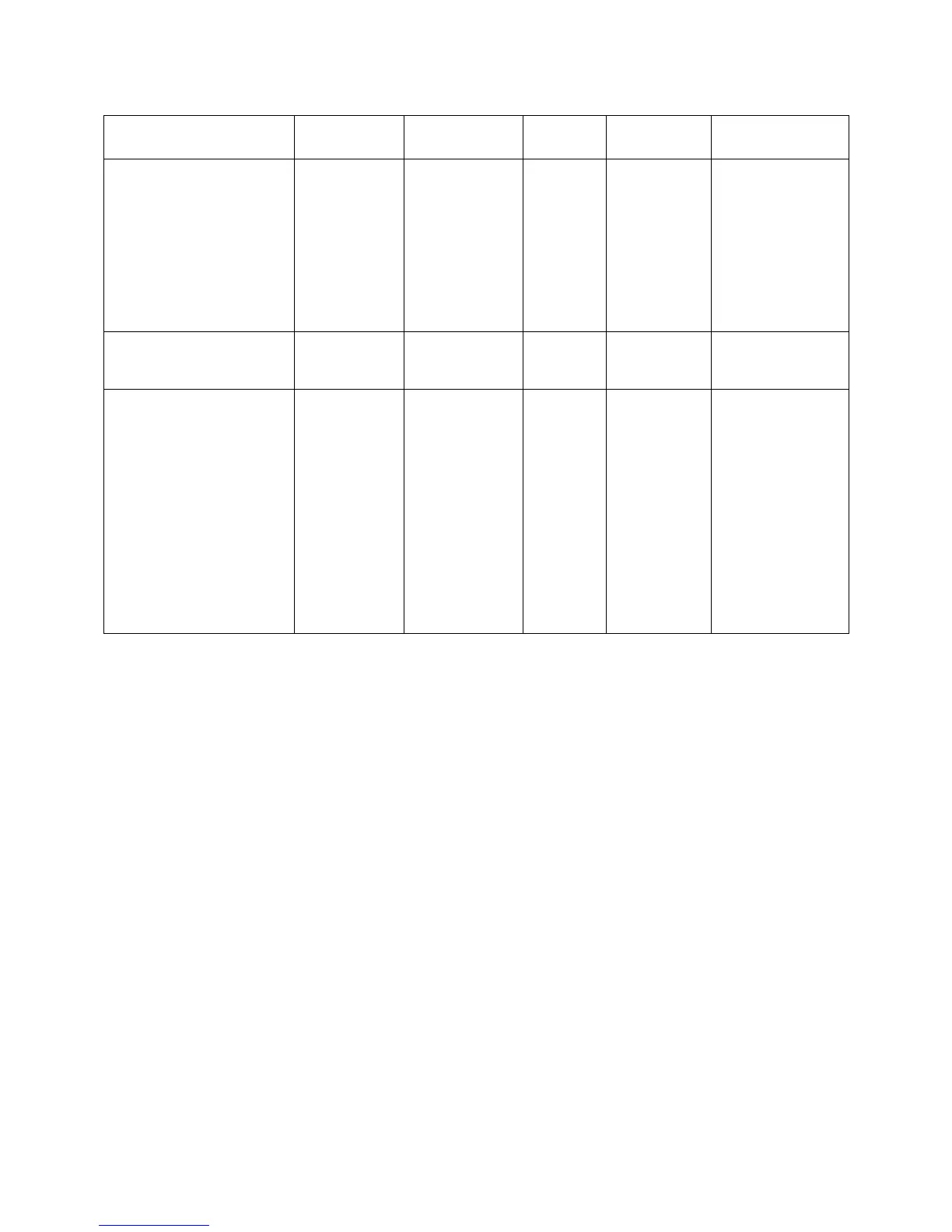

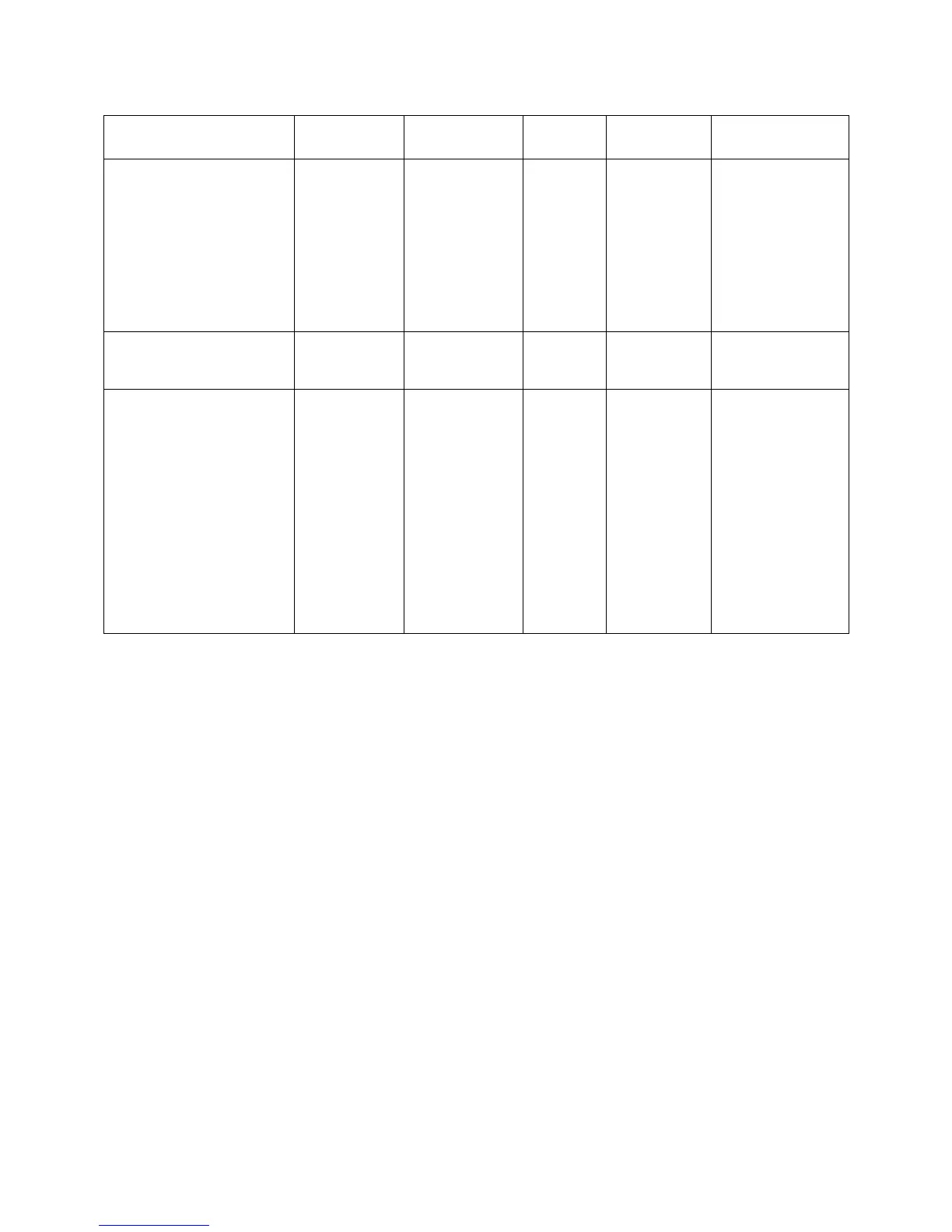

4.12: Hydro-Action

®

Plant Condition Chart

Sludge Volume Test

Characteristics

Black particles

In sludge.

Sludge does not

settle well.

Chunks of

floating material

above main

sludge layer.

Solids do not

separate

from liquids well.

Very little

settling usually

5-10 %.

Septic odor.

Very little

settling.

Sludge

particles

are

very small.

Same

as

organic

under

loading.

20-60%

particles.

Particles

resemble

small

pieces

of sponge.

Diffuser stones

may need to

be changed

to increase

dissolved O

2

level and

maintain

chocolate color.

If chocolate

color cannot

be maintained,

then the plant

will have to

be pumped.

(*3)

Look for

ways

to increase

organic

load.

Refrain

from

or reduce

the use of

toxic

substances.

(*2)

Reduce flow

of liquid to

designed GPD.

(*1)

*(1). Volumetric overloading (flow rate exceeds designed flow rate) could be caused by a

number of things. The most common are leaky toilets or faucets. Only sanitary waste (sinks,

tubs, washing machines, toilets, etc.) should be allowed in the Hydro-Action

®

plant. To check if

excess water is entering the plant, observe plant discharge point when house facilities are not in

use.

*(2). Find out if owner is using large amounts of chemicals such as unusual amounts of bleach,

disinfectants, photographic wastes, etc. Also check to see that water softener backwash is not

allowed in plant. This can cause a chemical imbalance and destroy needed bacteria. Backwash

should be routed to a separate disposal area. Any unusual types of waste not normally

associated with a household should be kept out.

*(3). When Hydro-Action

®

plant and pretreatment tank are being pumped, a qualified service

technician should oversee the job. Care should be taken not to damage internal components.

Plant and pretreatment tank should be washed and cleaned as they are being pumped. The

waste from the tanks should be disposed of in compliance with state and federal law. Hydro-

Action

®

recommends pumping the plant every 2 to 6 years; however, there is not a set time

because loading varies from household to household. Care should be taken when pumping

plant and pretreatment tank. Empty tanks can be hydraulically displaced (float tank) by ground

water. If soil is water-saturated tanks should not be completely emptied. Wasting sludge (solids)

can be accomplished without completely empty tanks.

Loading...

Loading...