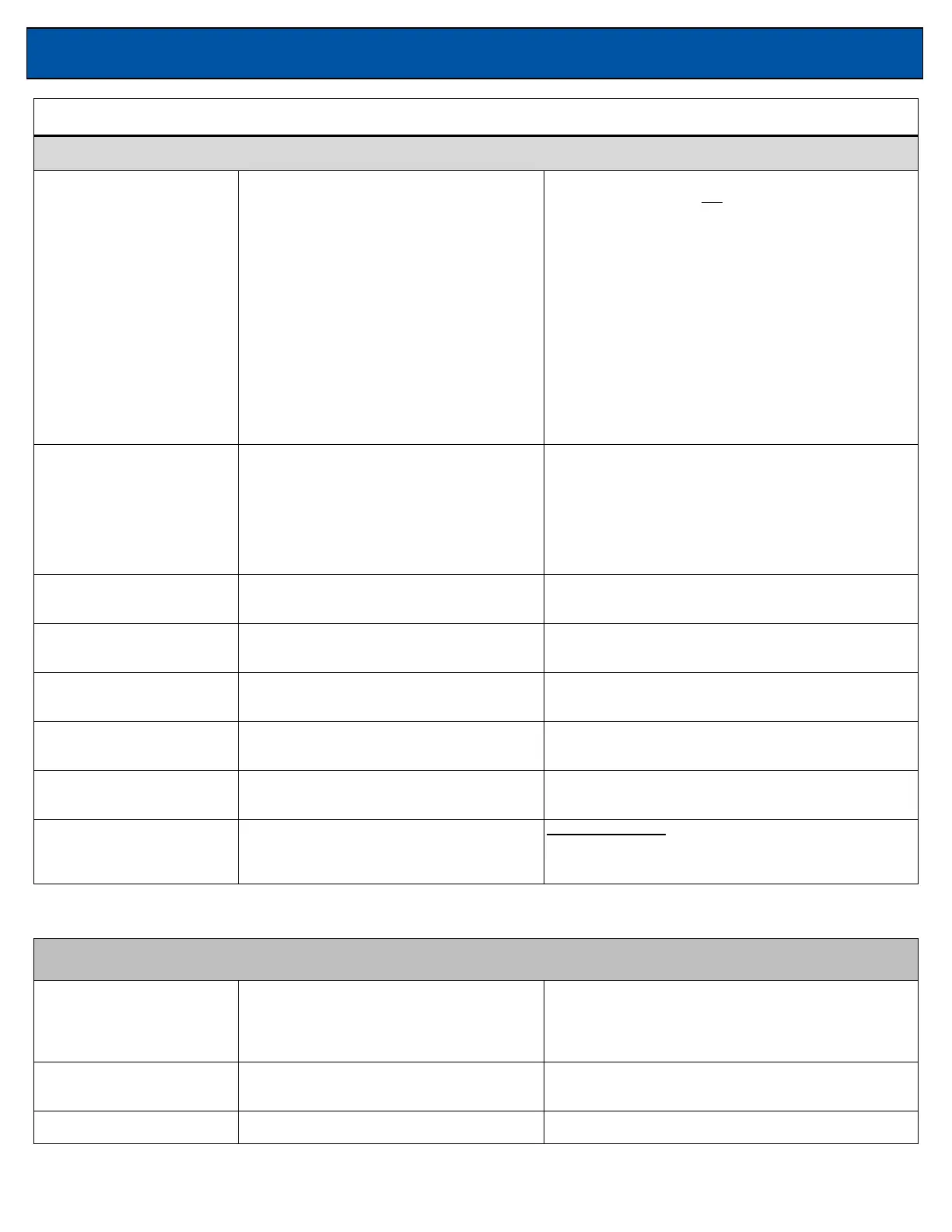

PROBABLE CAUSE

(The most recurring probable cause is listed first)

REMEDY

(Repairs should only be made by a qualified technician)

Heating / Burner System – Natural Gas or Liquid Propane Fired

Pilot will not light. Burner will not fire.

Trigger not pulled.

Thermostat not turned up.

Poor ground.

Gas valve turned off.

No voltage to valve.

Pilot orifice plugged.

Defective ignition module.

Defective pressure switch.

Defective transformer.

Defective flow switch.

Defective thermostat.

Faulty rocker switch.

Igniter not working.

Turn switch on. Press the reset switch.

Pull trigger. Burner should fire only when the trigger is pulled.

Adjust thermostat up.

Check & clean ground connections.

Turn gas valve on.

Check for 24 VAC between pilot valve (PV) & PV/MV. Valve will operate

between 20.5 & 28.5 VAC.

Remove orifice & clean.

Check for 24 VAC incoming @ 24v & 24v ground. (If you detect voltage

to module, but not through module, replace).

Check for 24v output. If no voltage, replace.

Replace.

Replace.

Replace.

Replace.

Test for spark. Test for continuity between ignition wire & ground.

WARNING! High voltage igniter can cause electrical shock.

Pilot lights, but burner will not fire.

Check for 24 VAC between main valve (MV) & PV/MV

when trigger pulled & unit on.

Failure to complete circuit to main valve.

Damaged or loose pilot assembly.

Insufficient or excessive gas pressure.

Check for continuity between ignition module ground &

If no VAC at the valve, replace module. If you get voltage, replace valve.

Check for controls continuity to main valve (thermostat, pressure switch,

flow switch).

Check for loose ignition wires.

Refer to installation guidelines. (Consult with a qualified gas technician)

Assure good ground.

Burner fires, but goes out.

Excess draft.

Protect from windy conditions. Install draft diverter.

Turn gas off. Call gas supplier.

NG or LP odor is present.

WARNING! Check all NG connections

with soap solution before operation.

Valve stuck.

Turn main gas valve off. Replace valve.

Discharge water temperature too high.

Incoming gas pressure to high.

Clean or replace spray nozzle, de-scale coil, & remove obstructions.

Lower gas pressure.

Replace spray nozzle with proper size.

Discharge water temperature not

reaching max. operating temperature.

Draft under burner manifold.

Increase gas pressure or install additional jets.

Prevent down draft with installation of down draft diverter. Prevent side

draft with nonflammable barrier.

Burner continues to fire even when

water is not being sprayed.

Faulty burner control circuit.

Main gas valve is stuck open.

Turn machine off immediately. Replace flow, vacuum, pressure, or

temperature switches.

Turn gas off. Replace main gas valve.

Valve/ Ignition module has been

subjected to moisture, had water

sprayed on it, or has been submerged

in water & does not work.

Flood or accidental spraying.

Replace valve / module: Do not attempt to repair or clean.

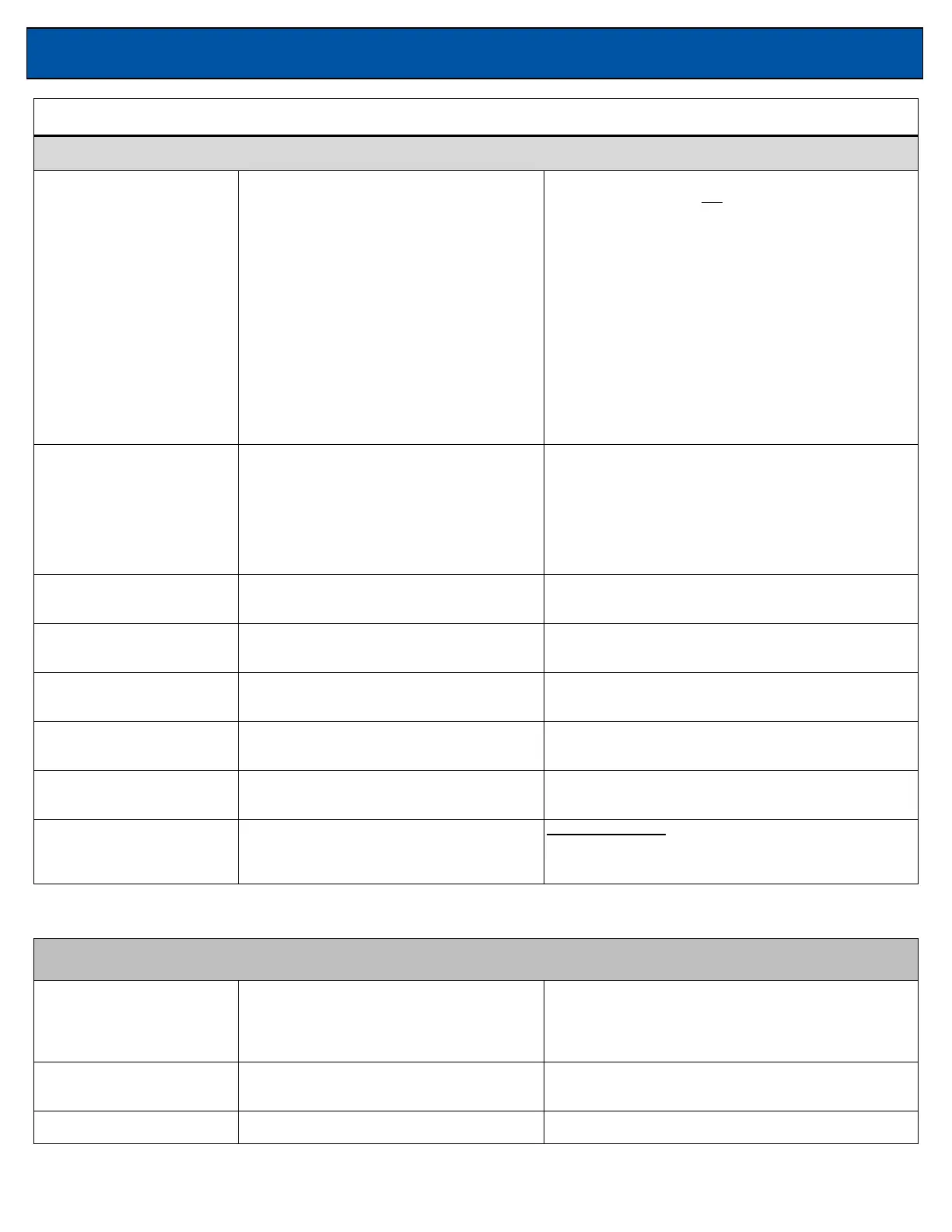

Heating / Burner System – Diesel Fired

(Additional Diesel Fired burner troubleshooting flow chart on next few pages)

Soot on coil exterior

Exhaust restricted

Air intake restriction

Improper voltage at burner motor

Adjust air band and fuel pressure to compensate

Increase air or decrease fuel. Coil may need cleaning

Remove restriction if obvious. Check for sooted coil

Remove restriction if obvious. Adjust air bands. Check fan

Check generator output if equipped. Check battery or charging system.

Improper or restricted fuel nozzle

Fuel gun assembly out of adjustment

Replace fuel nozzle

Adjust gun assembly location

Burner “Puffs” black smoke

Too much fuel pressure

Not enough air flow

Adjust fuel pressure at fuel pump

Adjust air bands

Loading...

Loading...