While your pressure washer has been produced with

quality materials and craftsmanship, you as the owner

have certain responsibilities for the correct care of the

equipment. Attention to regular preventative

maintenance procedures will assist in preserving the

performance of your equipment.

Contact your Hydro Tek dealer for maintenance. A

small investment in preventative maintenance will add

many hours to the life of your pressure washer.

Perform maintenance more often under severe

conditions. Do not spray high-pressure water onto the

machine. Not all maintenance items apply to all

machines.

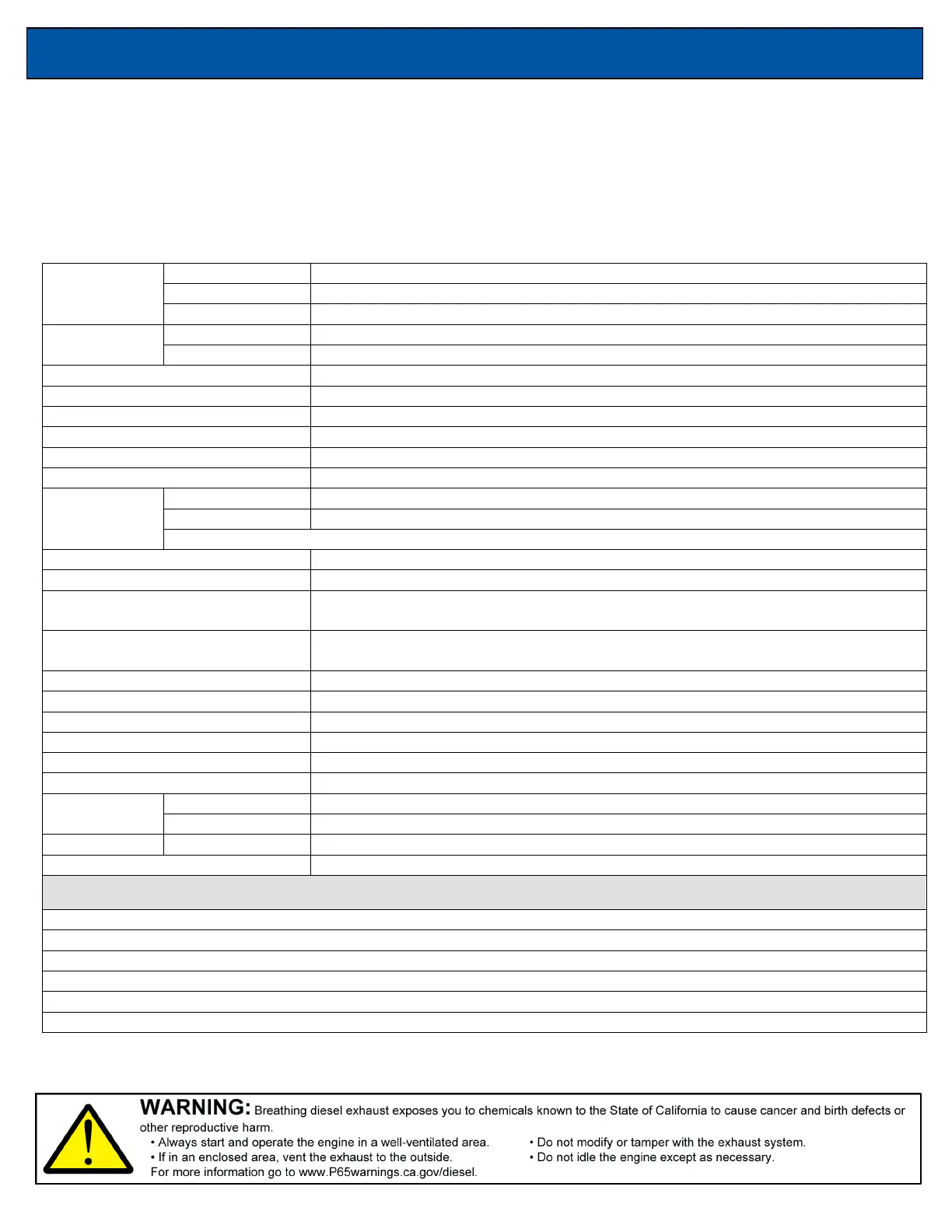

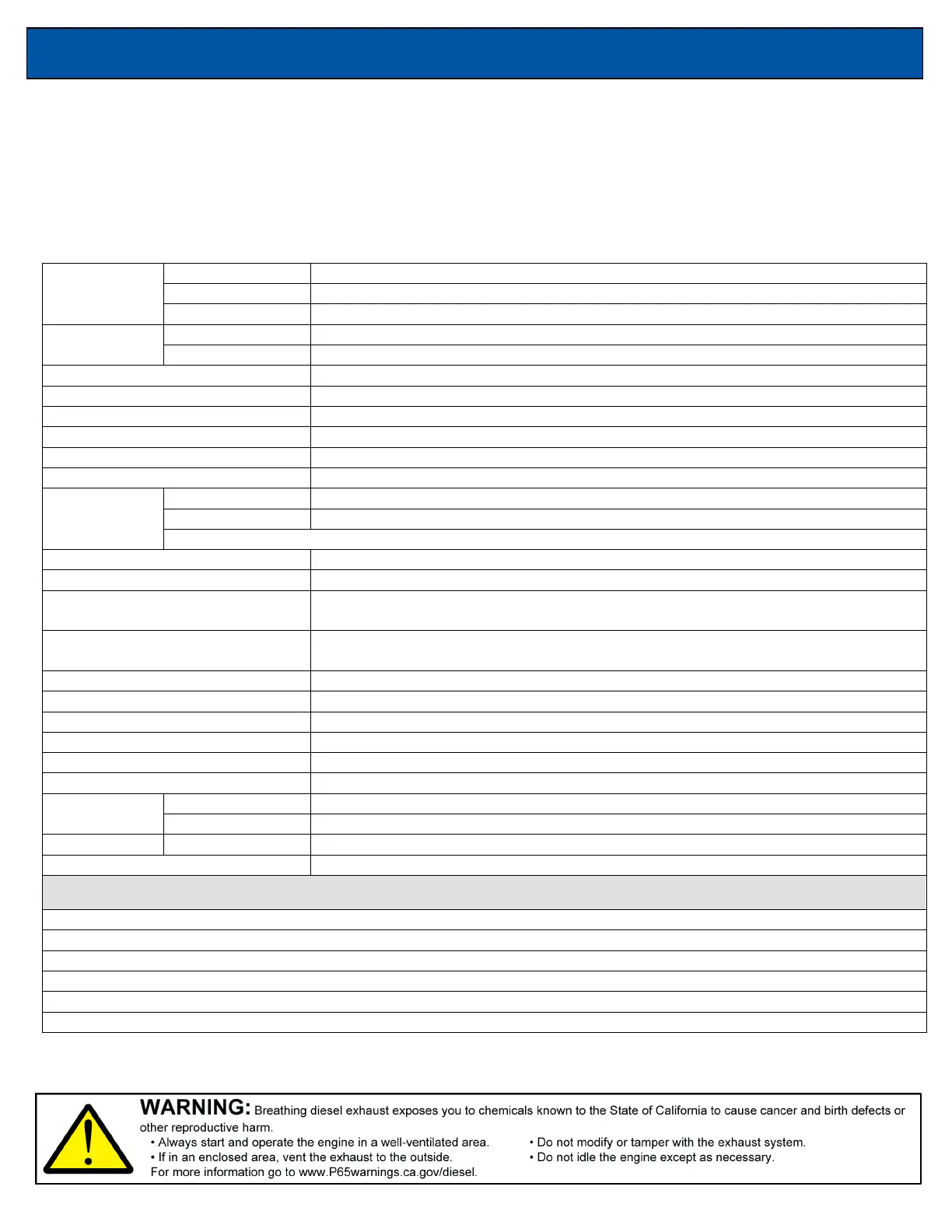

MAINTENANCE SCHEDULE**

After first 5 hours then every 100 hours especially in high ambient temperatures

Gas engine: every 100 hours / Diesel engine: refer to engine manual

Check daily (maximum 50% antifreeze)

Check monthly 12V DC Burner Systems: Replace battery every 2 years

Replace / Inspect Fuel Lines

After first 5 hours, then every 6 months or 500 hours

Axial pumps come filled with synthetic oil, which does not require changing

Clean/Replace Burner Filter

Monthly (More often if fuel quality is poor)

Fasteners / Exhaust Elbow

Periodically check your exhaust elbow and tighten all fasteners throughout

machine that may have come loose during running vibration or road travel

Burner Adjustment/Cleaning

Periodically (Check light sensing CAD cell control circuit and clean if needed)

Annually (Burner adjustment must be set to #1 smoke setting)

Annually (More often if required)

Every 6 months, or earlier if needed

Clean Water Screen/Filter

Weekly (More often if required)

Every 6 months (more often if required)

Monthly (Check tires for condition, tighten lug nuts, grease & check bearings)

MAINTENANCE INFORMATION

Cat Hydraulic, non-detergent 10w 40 ISO 68

Hydraulic, non-detergent SAE 30w

General, non-detergent SAE 30w

** Check the engine or motor manufacturer’s service guide for additional maintenance items and specific high

ambient temperature oil selection.

PREVENTATIVE MAINTENANCE SCHEDULE

Loading...

Loading...